Contents

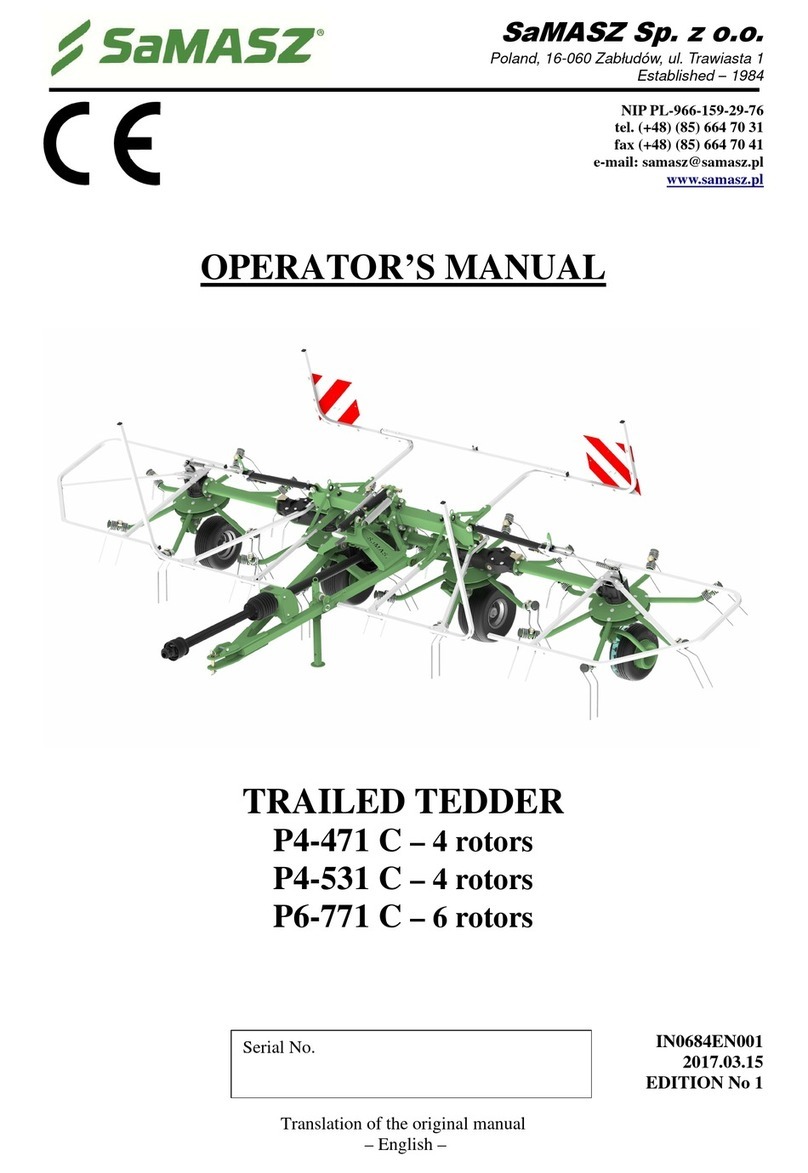

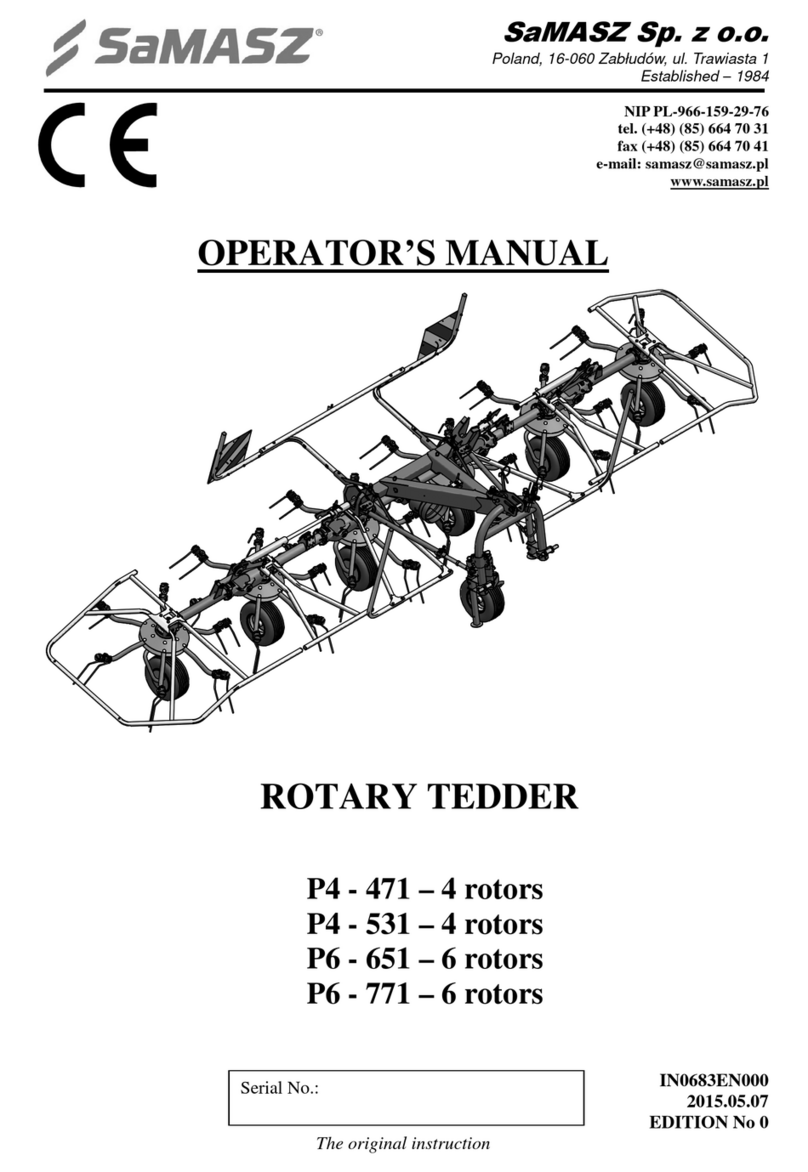

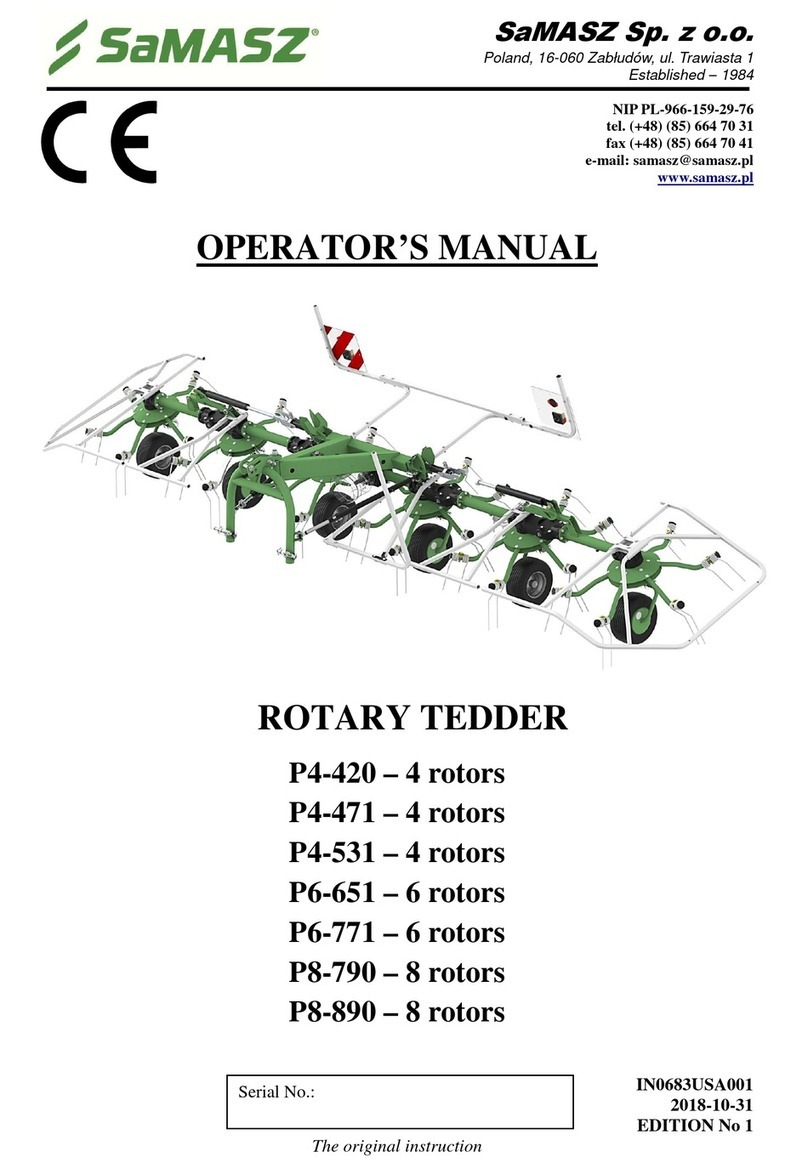

1. IDENTIFYING THE MACHINE..................................................................................................... 4

2. INTRODUCTION...................................................................................................................... 4

3. PROPER USE ......................................................................................................................... 5

3.1. Technical data ..................................................................................................................................5

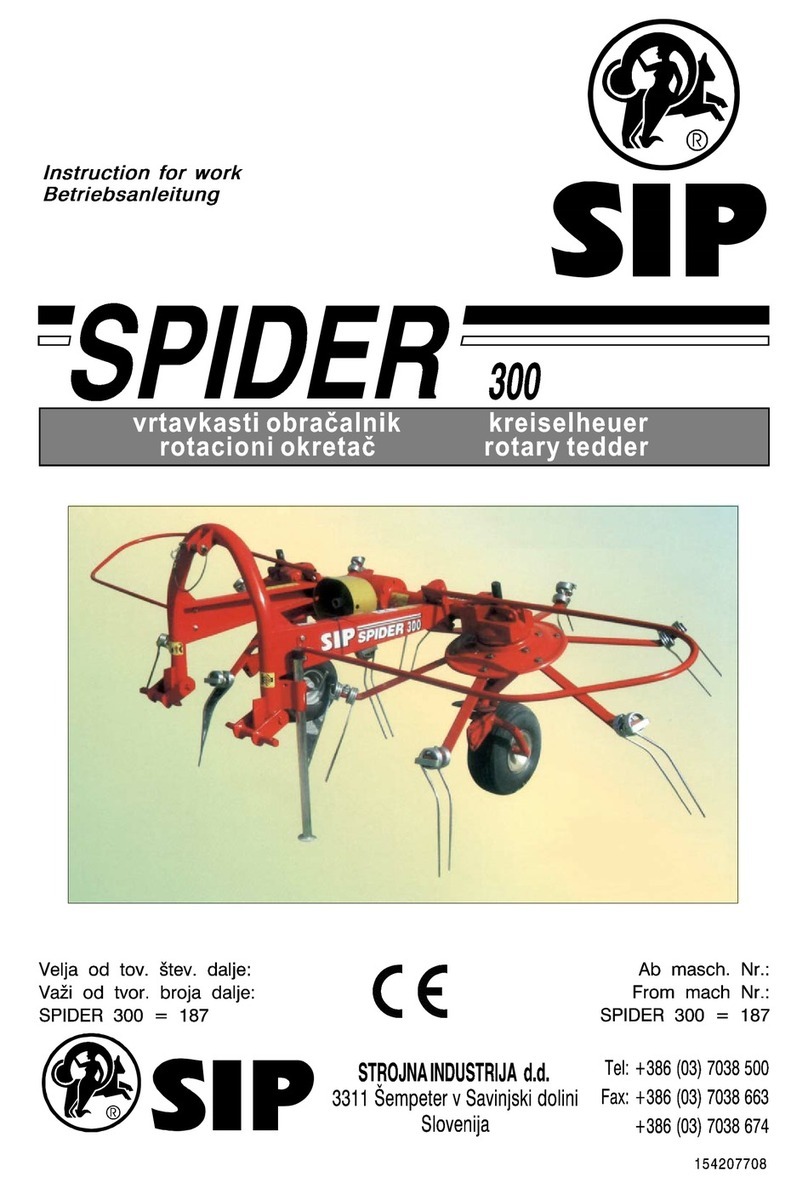

3.2. Design of trailed rotary tedder............................................................................................................6

3.3. Standard equipment and spare parts..................................................................................................7

4. SAFETY ADVICE ..................................................................................................................... 7

4.1. Safety rules and regulations...............................................................................................................7

4.2. Qualifications of operator..................................................................................................................9

4.3. Conditions of connecting tedder with vehicle....................................................................................10

4.4. Transport........................................................................................................................................10

4.4.1. Putting the machine onto another vehicle for transport..............................................................10

4.5. Working parts..................................................................................................................................11

4.6. PTO shaft........................................................................................................................................11

4.7. Hydraulic assembly .........................................................................................................................11

4.8. Residual risk ...................................................................................................................................12

4.8.1. Residual risk evaluation............................................................................................................13

4.9. Warning decals ...............................................................................................................................13

5. USE OF TEDDER ....................................................................................................................16

5.1. Attaching the tedder to the tractor ...................................................................................................16

5.2. Tedder hydraulics control ................................................................................................................16

5.3. Preparing the tedder for transport....................................................................................................17

5.4. Preparing the tedder for transport on public roads............................................................................22

5.5. Mounting PTO shaft ........................................................................................................................23

5.6. Switching from transport to working position ...................................................................................24

5.7. Preparing the tedder for work...........................................................................................................25

5.8. Operation........................................................................................................................................28

5.8.1. Tedding on the edge of the field ...............................................................................................28

5.9. Removing clogging and jams ...........................................................................................................29

5.10. Dismounting machine from tractor ............................................................................................30

6. MOUNTING AND ADJUSTMENTS..............................................................................................30

6.1. Mounting of the tines ......................................................................................................................30

6.2. Daily maintenance...........................................................................................................................31

6.3. After-season maintenance and storing .............................................................................................31

6.3.1. Restarting the machine after storing period...............................................................................31

7. LUBRICATION.......................................................................................................................32

7.1. Angular gearboxes for carousels......................................................................................................32

7.2. Vertical gearboxes ..........................................................................................................................32

7.3. Main gears......................................................................................................................................33

7.4. Joints .............................................................................................................................................34

7.5. Risks present when lubricating.........................................................................................................35

8. DEFECTS AND THEIR REPAIRS.................................................................................................35

9. DISASSEMBLY AND WITHDRAWAL FROM USE............................................................................36

9.1. Repair .............................................................................................................................................36

9.2. Demontage and scrapping ...............................................................................................................36

10. WARRANTY CARD .................................................................................................................36

11. WARRANTY TERMS ...............................................................................................................37

11.1. Warranty claims procedures......................................................................................................37

11.2. Warranty repairs record ............................................................................................................38