The Specialist In Drum Handling Equipment

Drum Pumps

morsedrum.com

Copyright 2019 - Morse Mfg. Co., Inc. Form PL26 (Updated 11 Jun, 2019) 8

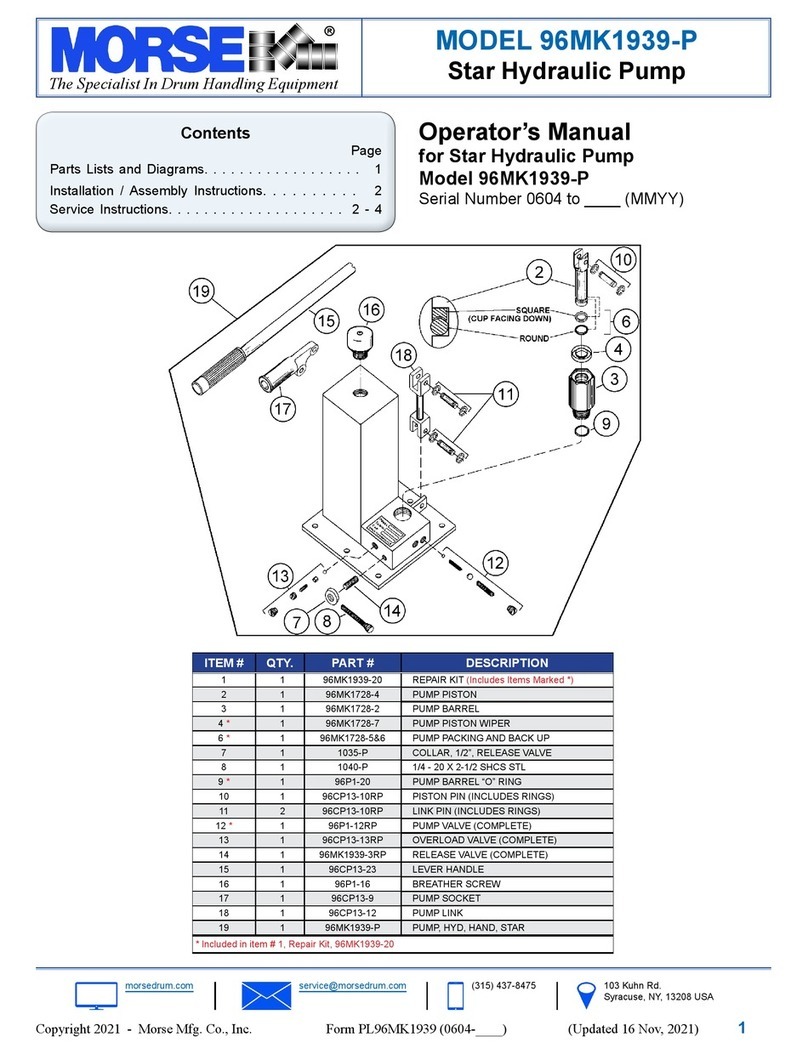

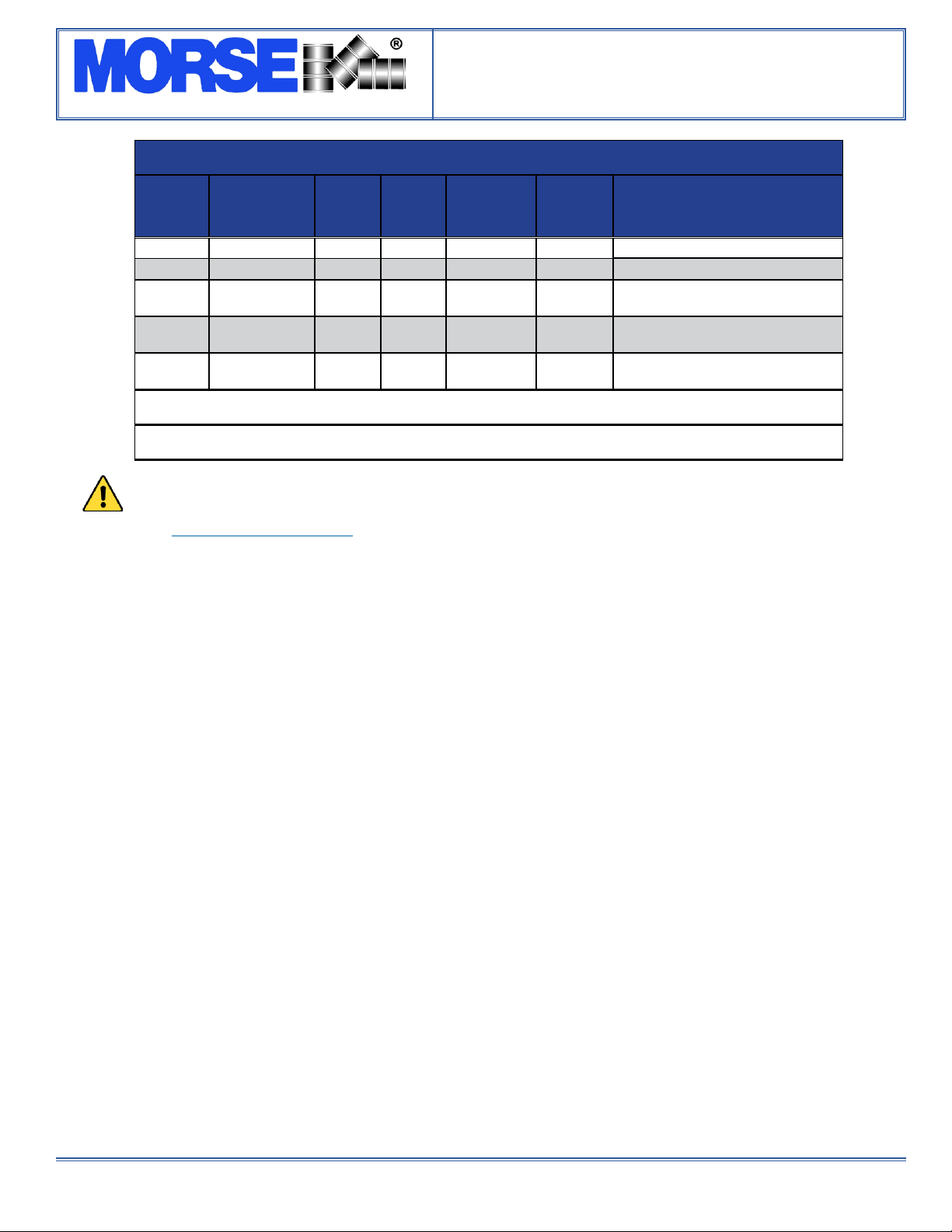

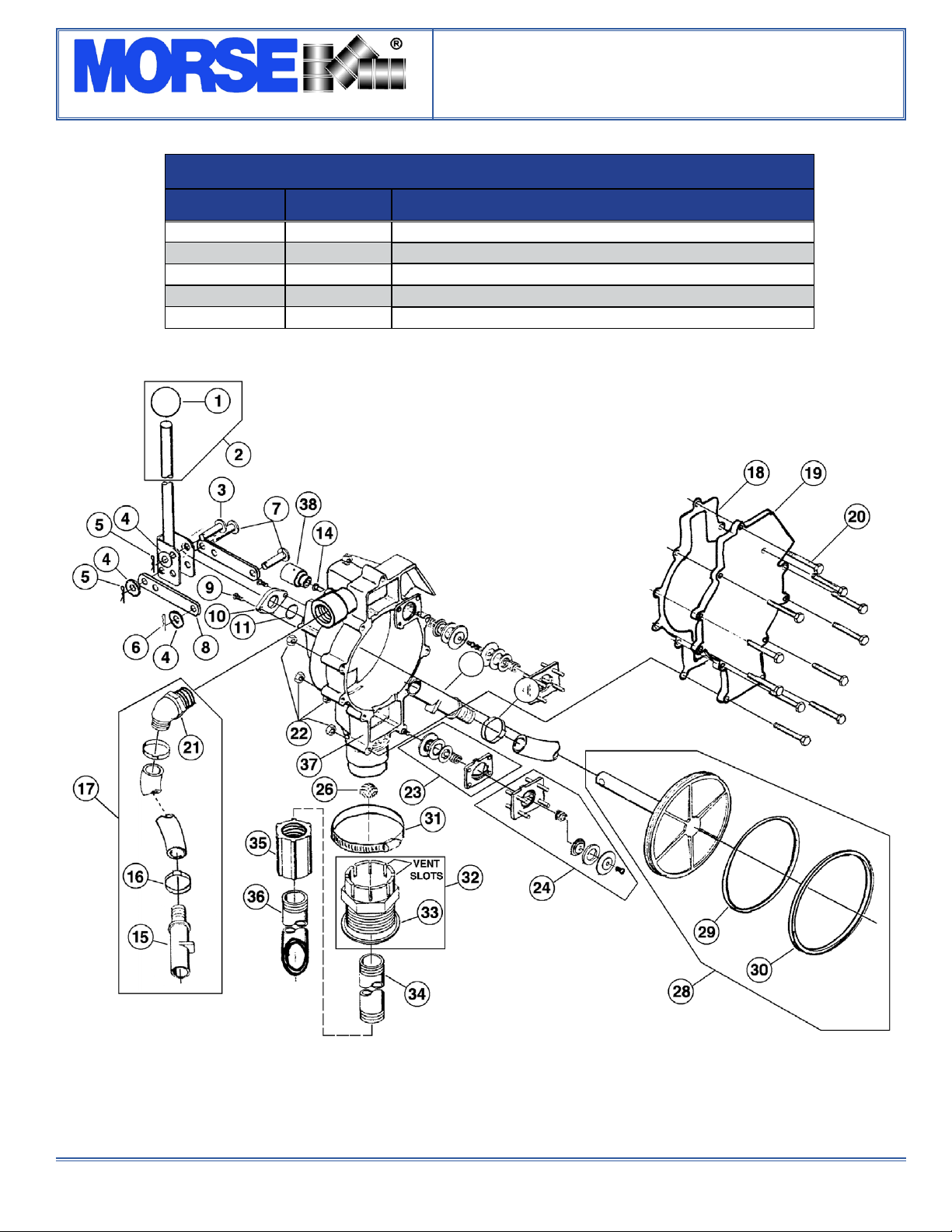

ITEM QTY. MODEL PART # DESCRIPTION

1 1 ALL PUMP MODELS 1049-40 KNOB, POLYPROPYLENE, PAC

2 1 ALL PUMP MODELS 1050-01 HANDLE ASM, PUMP, PAC

3 1 ALL PUMP MODELS 1053-00 PIN, CLEVIS 5/16 X 1-1/8, PAC

4 4 ALL PUMP MODELS 1380-90 WASHER, FLAT, NYLON, PAC

5 2 ALL PUMP MODELS 1379-00 CLIP, HAIRPIN, SMALL, PAC

6 1 ALL PUMP MODELS 1027-00 CLIP, HAIRPIN, LARGE, PAC

7 2 ALL PUMP MODELS 1031-00 PIN, CLEVIS, 5/16 X 1-1/4 PAC

8 2 ALL PUMP MODELS 1052-00 LINK, PLATED STEEL, PAC

9 2 ALL PUMP MODELS 1348-10 SCREW, 10-14 X 3/4 SS, PAC

10 1 26, 27-1AE, 27-4AV 1032-30 PLATE, RETAINING, PE, PAC

10 1 28-5BV, 28-6BE 1032-90 PLATE, RETAINING, HALAR, PAC

11 1 27-1AE, 28-6BE 1030-72 O-RING, PISTON ROD, EPDM PAC

11 1 26, 27-4AV, 28-5BV 1030-73 O-RING, PISTON ROD, VITON PAC

14 1 27-1AE, 28-6BE 1040-72 VACUUM BREAKER, EPDM, PAC

14 1 26, 27-4AV, 28-5BV 1040-73 VACUUM BREAKER, VITON, PAC

15 2 26, 27-1AE, 27-4AV 1325-30 NOZZLE, NO-LEAD, PE, PAC

15 1 28-5BV, 28-6BE 1325-90 NOZZLE, NO-LEAD, HALAR, PAC

16 2 ALL PUMP MODELS 1044-12 CLAMP, HOSE, CRIMPED, SS, PAC

17 1 26, 27-1AE, 27-4AV 1342-02 HOSE, PVC W/ PE NOZZLE, PAC

17 1 28-5BV, 28-6BE 1342-92 HOSE, PVC, HALAR NOZZLE, PAC

17 1 26, 27-1AE, 27-4AV 1342-04 HOSE, NITRILE, PE NOZZLE, PAC

17 1 28-5BV, 28-6BE 1342-94 HOSE, NITRILE, HALAR NOZZLE

17 1 26, 27-1AE, 27-4AV 1342-05 HOSE, EPDM W/ PE NOZZLE

17 1 28-5BV, 28-6BE 1342-95 HOSE, EPDM, HALAR NOZZLE, PAC

17 1 26, 27-1AE, 27-4AV 1342-07 HOSE, CLPE W/ PE NOZZLE, PAC

17 1 28-5BV, 28-6BE 1342-97 HOSE, CLPE, HALAR NOZZLE, PAC

18 1 27-1AE, 28-6BE 1204-72 GASKET, COVERPLATE, EPDM, PAC

18 1 27-4AV, 28-5BV 1204-73 GASKET, COVERPLATE, VITON, PAC

18 1 26 1204-90 GASKET, COVERPLATE, CORK, PAC

19 1 26, 27-1AE, 27-4AV 1209-30 COVERPLATE, PE, RED, PAC

19 1 28-5BV, 28-6BE 1209-60 COVERPLATE, RYTON, BLACK, PAC

20 11 26, 27-1AE, 27-4AV 1206-00 SCREW, 1/4-20 X 2, PAC

20 11 28-5BV, 28-6BE 1206-10 SCREW, 1/4-20 X 2 SS, PAC

21 1 26, 27-1AE, 27-4AV 1214-30 ADAPTER, HOSE, PE, 60DEG, PAC

21 1 28-5BV, 28-6BE 1214-90 ADAPTER, HOSE, HALAR 60DEG PAC

22 11 26, 27-1AE, 27-4AV 0721-00 NUT, 1/4-20 HEX, PLATED, PAC

ITEM QTY. MODEL PART # DESCRIPTION

22 11 28-5BV, 28-6BE 0721-10 NUT, 1/4-20 HEX, SS, PAC

23 2 27-1AE 1340-02 VALVE ASM, SMALL, PE EPDM PAC

23 2 26, 27-4AV, 28-5BV 1340-03 VALVE ASM, SMALL PE VITON PAC

23 2 28-6BE 1340-92 VALVE ASM SMALL, HALAR, EPDM

23 2 28-6BE 1340-93 VALVE ASM SMALL, HALAR VITON

24 2 27-1AE 1341-02 VALVE ASM LARGE, PE EPDM, PAC

24 2 26, 27-4AV, 28-5BV 1341-03 VALVE ASM, LARGE PE VITON, PAC

24 2 28-6BE 1341-92 VALVE ASM LARGE, HALAR EPDM

24 2 28-6BE 1341-93 VALVE ASM LARGE, HALAR VITON

26 1 ALL PUMP MODELS 1038-10 SCREEN, FILTER, SS, PAC

28 1 27-1AE 1338-02 PISTON ASM, PE, EPDM, PAC

28 1 26, 27-4AV, 28-5BV 1338-03 PISTON ASM, PE, VITON, PAC

28 1 28-6BE 1338-92 PISTON ASM, HALAR, EPDM, PAC

28 1 28-6BE 1338-93 PISTON ASM, HALAR, VITON, PAC

29 1 27-1AE, 28-6BE 1029-72 O-RING, PISTON, EPDM, PAC

29 1 26, 27-4AV, 28-5BV 1029-73 O-RING, PISTON, VITON, PAC

30 1 26, 27-1AE, 27-4AV 1028-90 RING, PISTON, TEFLON, PAC

30 1 28-5BV, 28-6BE 2024-90 RING, PISTON, TEFLON, THICKER

31 1 ALL PUMP MODELS 1056-10 CLAMP, BUNG ADAPTER, SS, PAC

32 1 26, 27-1AE, 27-4AV 1043-01 ADAPTER, PE, CORK NITRILE, PAC

32 1 28-6BE 1201-92 ADAPTER, HALAR W/ EPDM, PAC

32 1 27-4AV, 28-5BV, 28-6BE 1201-93 ADAPTER, HALAR W/ VITON, PAC

33 1 26, 27-1AE, 27-4AV 1381-90 GASKET, BUNG ADAPTER, PAC

33 1 28-6BE 1822-72 O-RING, BUNG ADAPTER, EPDM PAC

33 1 28-6BE 1822-73 O-RING, BUNG ADAPTER VITON PAC

34 1 26, 27-1AE, 27-4AV 1007-30 TUBE, EXTENSION, 16-1/2 PE PAC

34 1 28-5BV, 28-6BE 1007-90 TUBE, EXTENSION, 16-1/2 TEFLON

35 1 26, 27-1AE, 27-4AV 1055-30 COUPLING, 1” NPT PE, PAC

35 1 28-5BV, 28-6BE 1055-90 COUPLING, 1” NPT HALAR, PAC

36 1 26, 27-1AE, 27-4AV 1045-30 TUBE, SUCTION, 16-1/2 PE, PAC

36 1 26, 27-1AE, 27-4AV 2029-30 TUBE, SUCTION, 10-1/4” PE, PAC

36 1 28-5BV, 28-6BE 1045-90 TUBE, SUCTION, 16-1/2 TEFLON

37 1 26, 27-1AE, 27-4AV 1022-30 HOUSING, PUMP, HALAR, PAC

37 1 28-5BV, 28-6BE 1022-60 HOUSING, PUMP, RYTON, PAC

38 1 26, 27-1AE, 27-4AV 2022-30 PLUG, VENT, PE, PAC

38 1 28-5BV, 28-6BE 2022-90 PLUG, VENT, HALAR, PAC