MODEL AD-1000

AUTOMATIC DRAIN

580 CARNEGIE STREET 1-800-227-2822

MANTECA, CA 95337 FAX 209-239-5114

www.motorguard.com

Rev 01/18 33152

The AD-1000 Automatic Drain is designed to drain accumulated water and oil from drain lines, condensate drop legs, receiver tanks and filters. The unit

features a top threaded port for ease of installation. A protective stainless steel screen, umbrella baffle and large sump area collect moisture, oil sludge

and dirt. An internal float drain automatically empties bowl of accumulated liquid while minimizing air loss.

FEATURES

Highly Visible, Ball-Float Type Sight Glass

Stainless Steel Screen

Non-Clogging Float-Type Drain

SPECIFICATIONS

Operating Temperature Range: 40 -120 F

Maximum Inlet Pressure: 175 PSI

Port Size: 1/2 NPT

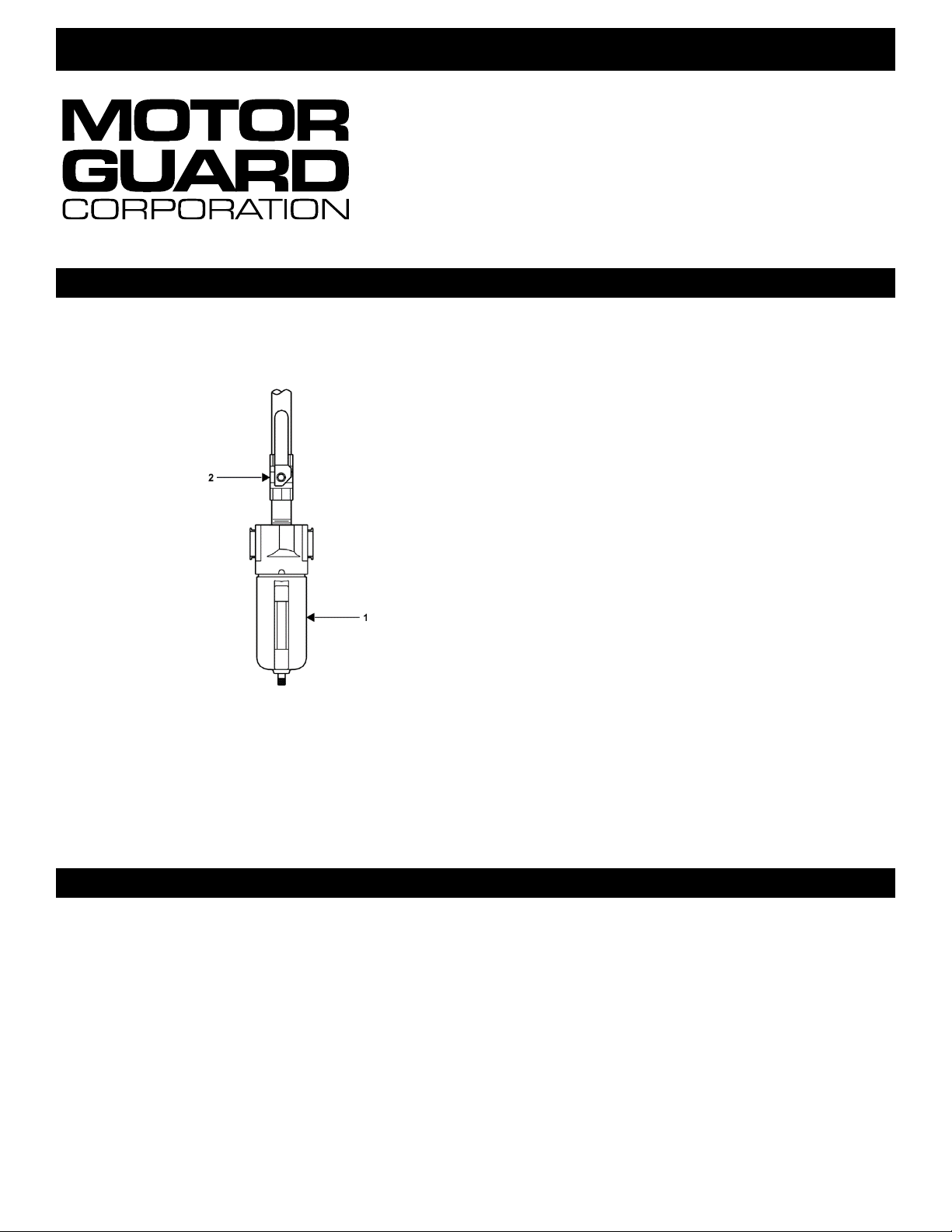

Before installing unit, relieve upstream pressure completely. Install unit (1) at lowest point in system and at the bottom of long vertical drops. Slope

adjacent piping toward drain for best results. Install manual shut-off valve (2) (field supplied) upstream of unit to facilitate service. Unit is designed for

installation in a 1/2" line, use appropriate fittings for installation in other line sizes. Apply pipe thread compound to male thread connections. Install unit

level with drain facing down.

WARNING: This product is intended for use on industrial compressed air systems only. It is not to be used on life support or breathing air

systems. Do not install where pressures or temperatures can exceed those listed above.

Before pressurizing, be sure bowl is turned fully clockwise. Pressurize slowly to avoid high-pressure surge.

Inspect daily for leaks.