3

UK

1 Safety instructions

• Please read this document prior to set-up of the unit� Ensure that the product is

suitable for your application without any restrictions�

• If the operating instructions or the technical data are not adhered to, personal

injury and/or damage to property can occur�

• Improper or non-intended use may lead to malfunctions of the unit or to un-

wanted effects in your application� That is why installation, electrical connec-

tion, set-up, operation and maintenance of the unit must only be carried out by

qualified personnel authorised by the machine operator�

• In order to guarantee the correct condition of the device for the operating time it

is necessary to use the device only for media to which the wetted materials are

sufficiently resistant (→ Technical data).

• The responsibility whether the measurement devices are suitable for the

respective application lies with the operator� The manufacturer assumes no

liability for consequences of misuse by the operator� Improper installation and

use of the units result in a loss of the warranty claims�

CAUTION

For medium temperatures above 50 °C (122 °F) some parts of the housing can

heat up to over 65 °C (149 °F)� Risk of burns�

►In this case do not touch the unit�

►Protect the housing against contact with flammable substances and uninten-

tional contact�

►Do not press the pushbuttons manually; instead use another object (e�g�

ballpoint pen)�

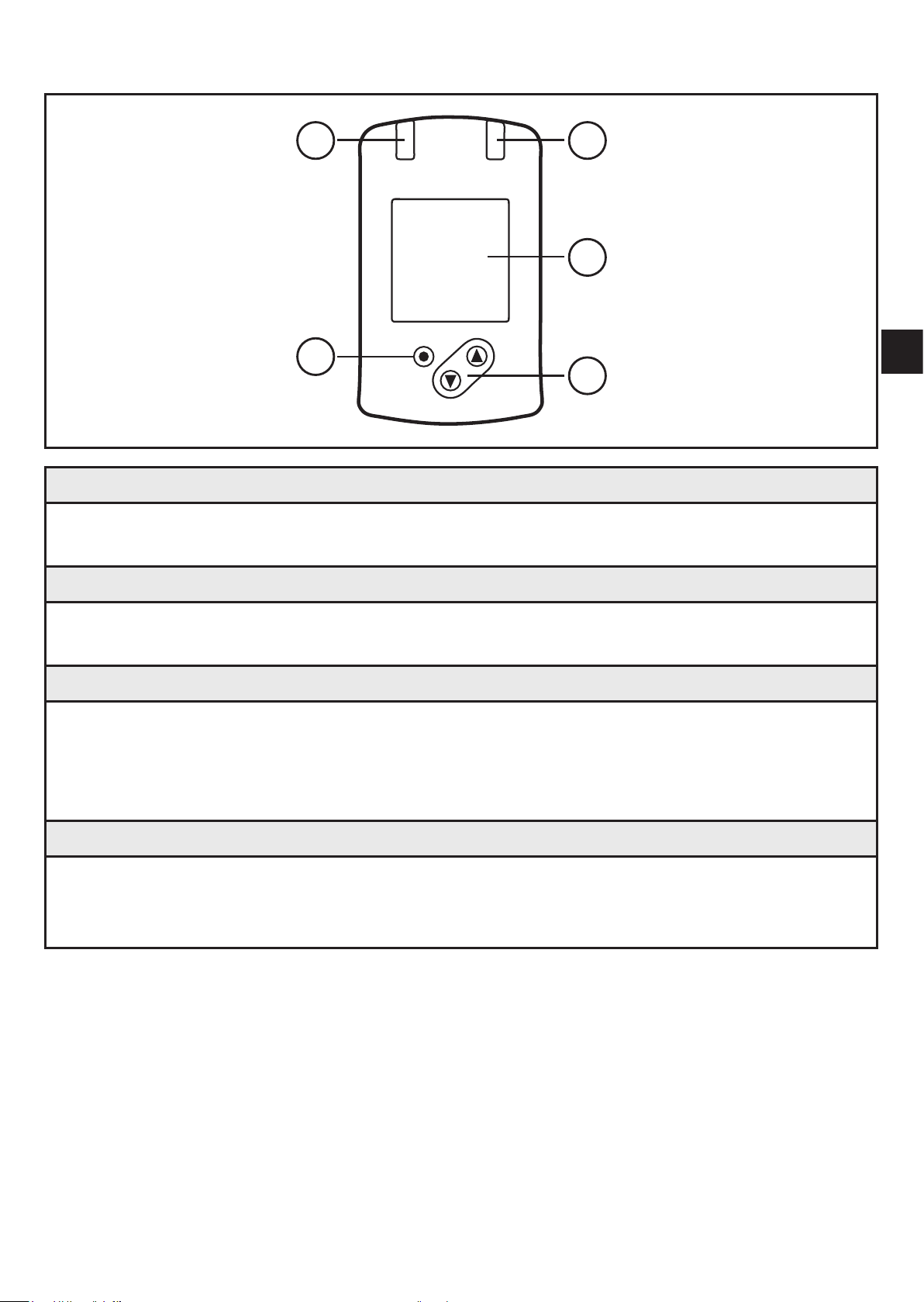

2 Functions and features

The unit monitors water-based fluids (water, deionised water, cooling water)�

It detects the two process categories volumetric flow and medium temperature�

Pressure Equipment Directive (PED):

The units comply with the Pressure Equipment Directive and are designed

and manufactured for group 2 fluids in accordance with the sound engi-

neering practice� Use of group 1 fluids on request�