Movax TAD30-2 User manual

Master

page b

Movax Oy

Tölkkimäentie 10

13130 Hämeenlinna

FINLAND

www.movax.com

marketing@movax.

User manual

from SN 1080 onwards

v1.0 2.12.2015

Soil Drill

TAD30-2

Master

page b

INDEX

1. INTRODUCTION .....................................................................................................................

2. SAFETYAND WARRANTY ...................................................................................................

2.1 SAFETY ......................................................................................................................

2.2 WARRANTY CONDITIONS .....................................................................................

3. MOVAX TAD30-2 ....................................................................................................................

4. USING MOVAX TAD – SOIL DRILL .....................................................................................

4.1 ATTACHING THE SOIL DRILL TO THE EXCAVATOR .........................................

4.2 FUNCTIONS ...............................................................................................................

4.3 CONNECTING AUGER TO KELLY BAR ................................................................

4.4 POSITIONING FOR DRILLING ...............................................................................

4.5 DRILLING ..................................................................................................................

5. MAINTENANCE ......................................................................................................................

5.1 LUBRICANTS FOR TAD30-2 ...................................................................................

5.2 DAILY MAINTENANCE ...........................................................................................

5.3 WEEKLY MAINTENANCE .......................................................................................

5.4 MONTHLY MAINTENANCE ...................................................................................

5.5 PIN ASSIGNMENT ON THE VALVE BLOCK (Manual, AutoC) ..........................

5.6 JOYSTICK .................................................................................................................

APPENDIX

1. GENERAL WARRANTY CONDITIONS

2. USED AUGERS

4

5

5

5

6

7

7

8

9

10

11

12

12

12

13

13

15

17

5.5 PIN ASSIGNMENT ON THE VALVE BLOCK (MCS Pro / Lite) ............................ 16

Master

page

1. INTRODUCTION

Movax TAD is a telescopic soil drill that can be

mounted on a standard excavator. TAD does not

require changes on a mechanical structure of the

excavator but can be used as attachment.

Read this instruction manual trough to get under-

standing of safe and allowed use of TAD soil drill.

This manual helps user to get started on site as well

as explains regular maintenance procedures.

Manual includes instructions of control buttons that

an operator use to control hydraulic functions on the

soil drill. This manual does not cover Movax auto

control system. Read separate Auto Steering manual

if your excavator is equipped with this system.

For spare parts there is separate manual `Spare Parts

Book`. Spare part ID number must be mentioned

when placing order. Also, remember to inform the

serial number, type and all the possible changes that

have been done on your Movax TAD. This insures

you will receive the correct spare parts.

Only an operator trained by a Movax manufacturer

or distributor is allowed to operate the soil drill.

Trained operators will receive the operator’s certi-

cate. This is also a condition of warranty.

INTRODUCTION

4

Master

page b

SAFETYAND WARRANTY

1. Movax operator must

be having an operator’s

certicate.

2. The soil drill has to

be connected to excava-

tor according to instruc-

tions. Note requirements

for hydraulic system of the

excavator and connections.

3. Maintenance has to be

performed according to the

instructions given in this

manual or Movax service

personnel.

4. Pressure relief valves

on a valve block on the soil

drill must not be set over

allowed maximum. Failing

to follow this may lead to

break down of telescope

lifting gear. Maximum

pressures are shown on a

hydraulic scheme on spare

part manual.

5. The soil drill should

be only used for soil drill-

ing purposes according to

instructions on this manual.

◊ Operator must be

trained for TAD soil drill

◊ Ensure there are no per-

sonnel in working area

◊ Obey safety instruc-

tions for excavator

◊ Check a connection

between the excavator and

the soil drill regularly and

always before use.

◊ Note stability and lift-

ing capability of the exca-

vator. It is recommendable

to avoid working sideways

to tracks.

◊ Avoid moving a boom

and an arm of the exca-

vator to positions where

accidental movement of

the excavator may cause

collision between soil drill

and cabin. Tilt the soil drill

away from cabin when lift-

ing it up or lowering down.

◊ Beware of drilled

bores in a ground. Bore is

weakening the surround-

ing ground and there is a

risk of falling into it. Never

leave open bores without

proper covering or isolat-

ing.

◊ Beware of over head

electric cables.

◊ Always check for

underground cables, pipes

and other structures before

drilling.

◊ Do not use the tel-

escope of the soil drill for

lifting.

◊ Lower the soil drill to

the ground before leaving

the cabin.

◊ Support and tie the soil

drill properly when loading

and transporting without

the excavator.

◊ Do not go under dril

when it is lifted.

◊ Beware that telescope

can slowly lower down

itself.

SAFETYAND WARRANTY

2.2 WARRANTY SAFETY

2.1 2.1 SAFETY

See general warranty condi-

tions for Movax products

(Appendix 1)

5

Master

page

3. MOVAX TAD30-2

MOVAX TAD30-2

Elevator

Telescope

Elevator

cylinder

Hydraulic

block

Rotation

motors

6

Master

page b

4. USING MOVAX TAD – SOIL DRILL

Before use read this users manual trough and ensure

you have comprehensive knowledge of its functions.

4.1 ATTACHING THE SOIL DRILL TO THE EX-

CAVATOR

Movax soil drill can be mounted on the excavator

with suitable quick hitch or with pins. For safety

reasons make sure that locking mechanism on the

quick hitch full lls the standards and is in good

working condition.

For the hydraulic functions the soil drill needs to be

connected to one way auxiliary circuit of the exca-

vator. In addition to this there is a need for drain-

age line that is connected directly to hydraulic tank

of the excavator. Minimum sizes of the piping are

shown in a table below.

Connect the drainage and the return lines before

connecting the pressure line. Ensure that all ball

valves on the excavator pipes are open if installed.

Hydraulic motors will be damaged if the lines are

not connected properly prior the use of the soil drill.

Also, keep all connectors clean and use protector

caps when not connected.

Then connect an electric cable that is needed to

control the functions of the drill. Electric connector

must also kept clean and dry for problem free opera-

tion.

HYDRAULIC REQUIREMENTS FOR TAD-30S

Pressure pipe / hose ø 30 mm / 1”

Return pipe / hose ø 30 mm / 1” or

42 mm / 1 ¼”

Drainage pipe / hose ø 7 mm / ⅜”

Oil ow, minimum* 75 l/min

Oil ow, maximum* 250 l/min

Relief setting 320 BAR

Return pressure, maxi-

mum 5 BAR

*Auger RPM is depending on the oil ow.

TAD30-2 11 – 74 1/min

USING MOVAX TAD – SOIL DRILL

7

Master

page

4.2 FUNCTIONS

Rotation. The auger is rotated by two axial piston

motors. TAD-30s has two different speeds for rota-

tion. Higher speed employs only one of the motors

with maximum torque of 15.000 Nm. Lower speed

mode engages both motors and delivers 30.000 Nm

of torque.

Lowering and raising the auger. Telescope and el-

evator mechanisms are used for lowering and raising

the auger during drilling. Keep the auger paralled

and centered to the bore at all times. Careless mov-

ing the boom or the arm may cause bending forces

to the telescope lead to break downs.

Movax TAD30-2 soil drill has telescopic kelly bar

with two moving extensions. Movement is imple-

mented with a hydraulic cylinder. The mechanism is

working two ways thus enabling the hydraulic push

and pull. During the drilling work the kelly bar can

be also released to oating mode.

Elevator refers to a lift mechanism on between main

body and a part that links the soil drill to the exca-

vator. Elevator is moving the drill up and down by

hydraulic cylinders. This can be used for reaching

the maximum depth but also for drilling or pulling

out at any depth as it creates same direction linear

movement as the telescope.

Side tilt. The soil drill tilts 30º both side ways. This

movement works with two hydraulic cylinders. The

tilt is used to straighten the drill when the excavator

is on slope or uneven surface. Tilt can be also used

for raked drilling.

USING MOVAX TAD – SOIL DRILL

8

Master

page b

4.3 CONNECTING AUGER TO KELLY BAR

The auger is mounted into the telescopic kelly

bar with bolt-on adapter that is changeable for

different size and shape bars. This enables the use

of the augers with different connection standard.

Ask you Movax dealer for needed type adapter.

Following procedure is easy and safe way for

mounting the auger. Pay attention to safety, never

go between moving parts.

1. Make sure the adapter is rmly bolted to the

telescope kelly.

2. Lay the auger on the ground and support the

end against solid rest, track of the excavator in

example.

3. Line up the soil drill and the auger.

4. Rotate the auger or the telescope until the kelly

bar and the box are in same position. Note the

position of the locking pin and hole.

5. Use telescope to push the kelly bar into the

auger.

6. Install the locking pin(s).

USING MOVAX TAD – SOIL DRILL

9

Master

page

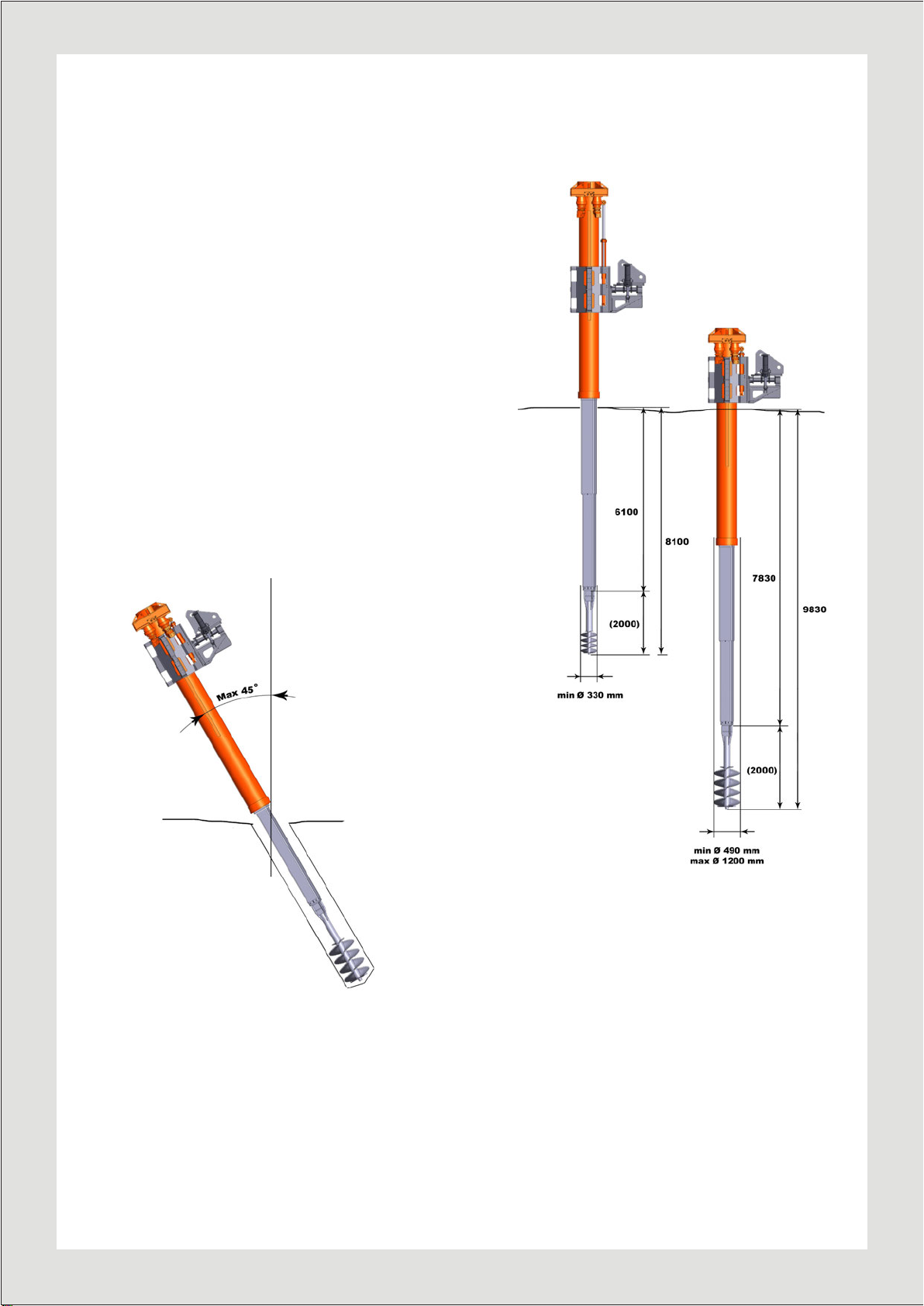

4.4 POSITIONING FOR DRILLING

Lift the soil drill upright position and move to

wanted location of drilling. The telescope is ide-

ally in a shortest position at the beginning and

the elevator roughly halfway or lover position.

Then use the boom of the excavator to position

the end of the auger about half metre above the

ground. Alignment can be done by moving the

arm, the bucket cylinder of the excavator and tilt

function on the soil drill.

Movax soil drill can be used also for raked piles.

Drilling angle must not exeed 45 degrees thus

drilling on horizontal position is not allowed.

Rotation of the telescope in too big inclination

can cause a damage to the mechanism used to

drive the telescope.

Working range measured to the end of the

telescope and with 2000 mm long auger.

USING MOVAX TAD – SOIL DRILL

10

Master

page b

4.5 DRILLING

Begin the drilling by starting the rotation clockwise.

Rotation speed can be set by changing the oil ow

from the excavator. This is easily done by chang-

ing the running speed of a diesel engine. TAD-30s

enables two different speeds by running one or two

motor at the time. Higher speed is in use by using

one motor and lower speed with higher torque when

running both motors. It is recommendable to start

with one motor and switch to two when more torque

is needed.

Rotating auger can be now lowered to the ground by

utilising the telescope. There are two ways of op-

erating telescope. It can be released to go down by

the gravity and a force created by the auger ights.

Other option is to push the kelly out hydraulically

and that way put more down force in a case that au-

ger is not cutting well into soil by its own weight.

The auger should be driven into the soil from 0.2 to

0.8 metres at time depending on the ground condi-

tion, size of the auger as well as the type of the

auger. Then stop the rotation and rotate some half

round counter clock wise to get the auger loose

from the cutting point. This may not be needed with

granular and very light soils. Pull the telescope in

until whole length of the auger is above the ground.

In addition to telescope movement the elevator can

be used to lift the auger up. In order to avoid bend-

ing the telescope tubes be cautious when moving

the boom, arm or bucket cylinder whilst the auger is

lovered into the ground or casing.

Remove the soil from the auger by rotating it coun-

ter clock wise.

USING MOVAX TAD – SOIL DRILL

11

Master

page

5. MAINTENANCE

5.1 LUBRICANTS FOR TAD-30

1. Lubricant for greasing points; grease

nipples, rotary gear, slide bearings and all

slides on the telescope and the elevator:

Open gear grease, greasing intervals on

chapters below.

2. Lubricant for planetary gears: 80W-90

API GL-5 gear oil. First change after 40

hours, then every 6 months or 250 hours.

5.2 DAILY MAINTENANCE

Check daily:

1. Hydraulic hoses and connections, pay

attention to possible damages, leakage and

loose fastening

2. Oil level of the planetary gear

3. The bolts on kelly bar end - check the

torque and tighten if needed

4. Slides on the elevator frame

5. Mechanical connection to the excavator

and the bolts connecting the adapter to the

drill

6. Tilt pin and fasteing of the tilt cyliders

Note. Do not operate the drill if any of the

mechanical or hydraulic components is

damaged or loose.

Grease daily:

1. Slide bearing in lower end of a frame

tube.

2. Slides on the elevator.

3. Telescopic kelly bar (may not be neces-

sary on daily basis).

Note 1. Continuous rotation of the drill is

not allowed while greasing the telescope

with the drill in horizontal position. The

rotation can be still used shortly to spin the

telescope around for better access for greas-

ing.

Note 2. Do not rotate when top cover is

open. There is a risk for hose failure.

MAINTENANCE

12

Master

page b

5.3 MAINTENANCE WEEKLY OR EVERY

40 HOURS

Check weekly:

1. Open the top cover and inspect the gear

wheels, clean if needed.

2. Inspect a rotary joint. Make sure there are

no leakages and check that the rotary joint

cannot turn around but a stopper is rmly

xed.

3. All points mentioned in a chapter DAILY

MAINTENANCE

4. Retract telescope, after that two grease

nipples comes visible (marked “A” in photo)

Grease weekly:

1. Gear wheels inside the top cover

2. Bearing of the rotary gear

3. Tilt pin and cylinder bearings.

4. Retract telescope, after that two grease

nipples comes visible (marked “A” in photo)

5.4 MONTHLY MAINTENANCE

1. Clean the gear wheel casing and telescope.

1.1. Open the top cover and remove the adapter

for the auger from the telescopic kelly bar

1.2. Clean the gear wheel casing and telescopic

kelly bar both inside and outside. Use high

pressure cleaner with hot water if available.

2. Inspect all related parts

3. Use new bolts for kelly bar adapter

4. Shim or change the slides on the elevator if

necessary

5. Inspect and lubricate all points mentioned in

the chapters DAILY -AND WEEKLY MAIN-

TENANCE.

MAINTENANCE

A

A

13

Master

page

6. Check the chain adjustment in the telescope.

6.1 Pull mechanically the telescope fully in to the

shortest length. You can ensure fully in position

with hand winch.

6.2 Tighten the nuts using special tool. Right mo-

ment is achieved by hand tightening when using

this tool. This way right tightness of retraction

chains is ensured.

MAINTENANCE

6.3 Under top cover can be found two springs

(marked “B” in photo). These springs must have 7

mm compression from free length to ensure right

tightness on extension chains.

B

B

14

Master

page

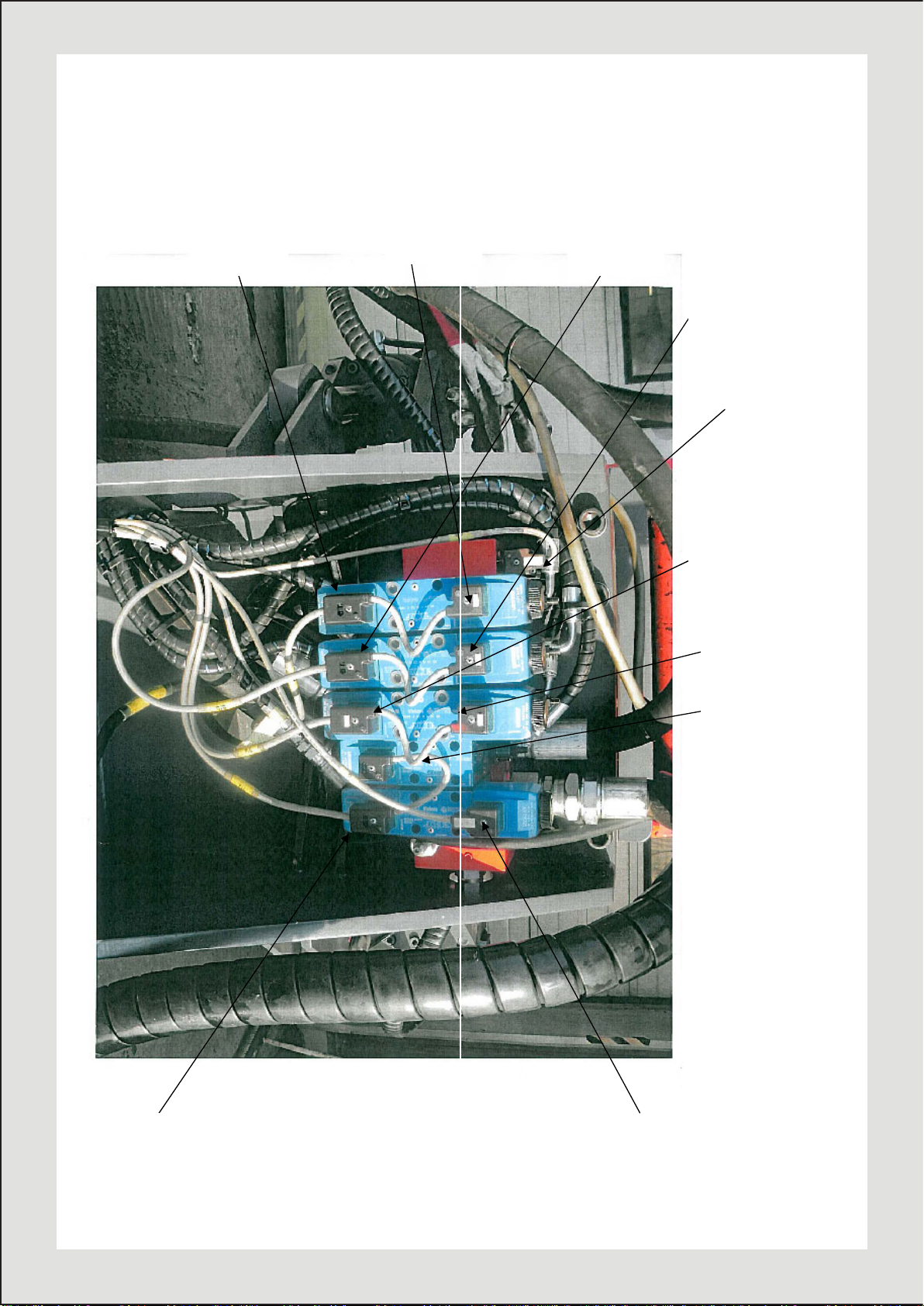

MAINTENANCE

s

Telescope up

Cable No.7

Telescope down Elevator down

Cable No.8 Cable No.6

Elevator up

Cable No.5

Rotation reverse

Motor 1

Cable No.2

Rotation forward

Motor 1

Cable No.9

Motor 2

Cable No.1

Tilt right

Cable No.3

Tilt left

Cable No.4

Auger

float

Cable No.10

Activation of

5.5 PIN ASSIGNMENT ON THE VALVE BLOCK0DQXDORU$XWR&FRQWUROV\VWHP

15

10

&DEOH

95/6

3/4

1/2

7/8

5.6 PIN ASSIGNMENT ON THE VALVE BLOCK AU-02-0-4 FOR MCS PRO AND MCS

LITE CONTROL SYSTEMS (CABLE 40438)

Wire No. Function

1 Elevator up

2 Elevator down

3 Tilt right

4 Tilt left

5 Rotation reverse motor 1

6 Rotation forward motor 1

7 Telescope up

8 Telescope down

9 Activation of motor 2

10 Auger oat

16

Master

page b

- 9 -

FUNCTION

TAD-30S

BUTTON OR

COMBINATION

Auger rotation reverse 1

High torque / low speed 2

Kelly up 3

Kelly down 4

Elevator up 5

Elevator down 6

Tilt left 7

Tilt right 8

Auger rotation / drilling clockwise

9

Kelly float on / off 9 + click 2

Joystick

65

9

1 2

3 4

7 8

10 11

TAD-30

FUNCTION BUTTON OR

COMBINATION

Auger rotation fast forward

Motor 1 9

Auger rotation fast reverse 1

Auger rotation forward

High torque (low speed)

Motor 1 and 2 9 + 2

Auger rotation reverse

(low speed) 1 + 2

Tilt right 3

Tilt left 4

Elevator up 5 + 11

Elevator down 6

Telescope up 7

Telescope down 8

Kelly oat on / off 9 + click 2

Drill straightening, automatic 9 + 11

5.JOYSTICK

17

! " # $ % # & ' # ( ) ' * + , , # ' $ % , # ' ' %

& ' , & ) # % + ' & # + ) , ) # , % # % , % ' ) ' %

+ ' # ' % , ' -

. / ) '

* ' # ' % . + % * ' # % %

! " # % # & ' #

( ) ' * + , ) % + # & ' ' % , % ' # # + # , ) % + % , ' #

( ) ' * +

! " # 0 % * % ' % ' % & & # ( ) ' * + % $ #

1 # # ' ' & * % % * '

# % , * % % % * * % ' $ # % , &

# 2 ' $ * % % + ' , * % &

3 , # ' ' % * '

' % & ' # 4

5 # + $ , , ) % ' + & * ' $ , # ' ' %

65 , ) % + % & & # ' % ) , ' % $ ' 6

! " # ' % * % ' $ # ' $

* ' 7 ' % & & ' # + ' , * # ) , %

, 5 % * * % ) % # ' * ' # 2 + ' , * # ) , % 6 * * # 6

! " #

# 5 , ) % + ' ' %

! " # # + $ % % % * % % ' 6&

5 , ) % + + 8 % , & ' + # ' & & % ) + , , # ' $ &

- & ' + ' ' %

# % , 4

5 9 + & ' $ ' $ * % : % % 7 % & % 7 , 5

65 ; # + $ % , , ) # * # ) , % 6 * # $ ' % ' % ) , ' % $ ' 6

! " # $ ' % ' % ) , ' % ' ' % ) , ' + ) & # & ' # ' * # ) ,

, 5 ; # + $ % , , ) # ) % ' $ % * * % + ) , ) # * * # 6

!

" #

# 5 ; # + $ % , , ) # 6 , ) % * ' + ' , 8 + # $ ' % ' % ) , ' %

$ ' 6

! " # ' % * % ' %

5 ; # ' , ' # ' , , % % 6)$ 6 # + $ # * # ) , %

APPENDIX 1

18

< ; # # ' ' & , # ' ' %

, ) % + + ) % % # # + $ # * # ) , # + $ # *

! " # ' % * % 7 '

( ) ' # 6

! " #

! " # % ' $ , $ % , # + $ , , # ' $ ' % , ' * ' , & ' % 7 ' '

' % & # ' % , # # + $ * # 6 , ) % + ' % , # 6

! " # # , ) % + $ % * & + % # & ' * '

; # ' % $ + & # % , # ' ' % ' & & * ' + ' & 6 % & # ) $ $ ' ' %

6 * ' % = # ' % * ) ' % % & # 6 $ ' ' % 7 # ' % * ) , 6 % & # '

> ?

+ & ' # ' % ' , , ) ' ' ' # 6 ' *

> ?

+ & ' 7 1 - . @ @ A

19

Please return completed warranty card to Movax Oy Ltd by email to m[email protected] or

by fax to +358 (0)3 616 1641or by mail to Tölkkimäentie 10, FI-13130 Hämeenlinna, Finland.

Warranty card can also be filled at www.movax.com.

WARRANTY CARD

Model

Serial number

Movax Oy Ltd grants a warranty to the delivered new equipment according to Movax warranty conditions. The

warranty period is 12 months and the warranty period starts when Movax Oy Ltd has delivered the equipment to

the customer. The delivery is considered made when the customer has received the equipment or Movax Oy Ltd’s

representative has installed the equipment as agreed. The warranty card is required for warranty coverage and it

helps in case of any warranty issues.

DISTRIBUTOR / DEALER (seller)

Company name:

Contact person:

CUSTOMER

Company name:

Contact person:

Address:

Phone:

Email:

MOVAX PRODUCT

Model:

Serial number:

Installation date:

Installation made by:

Additional information:

20

Table of contents