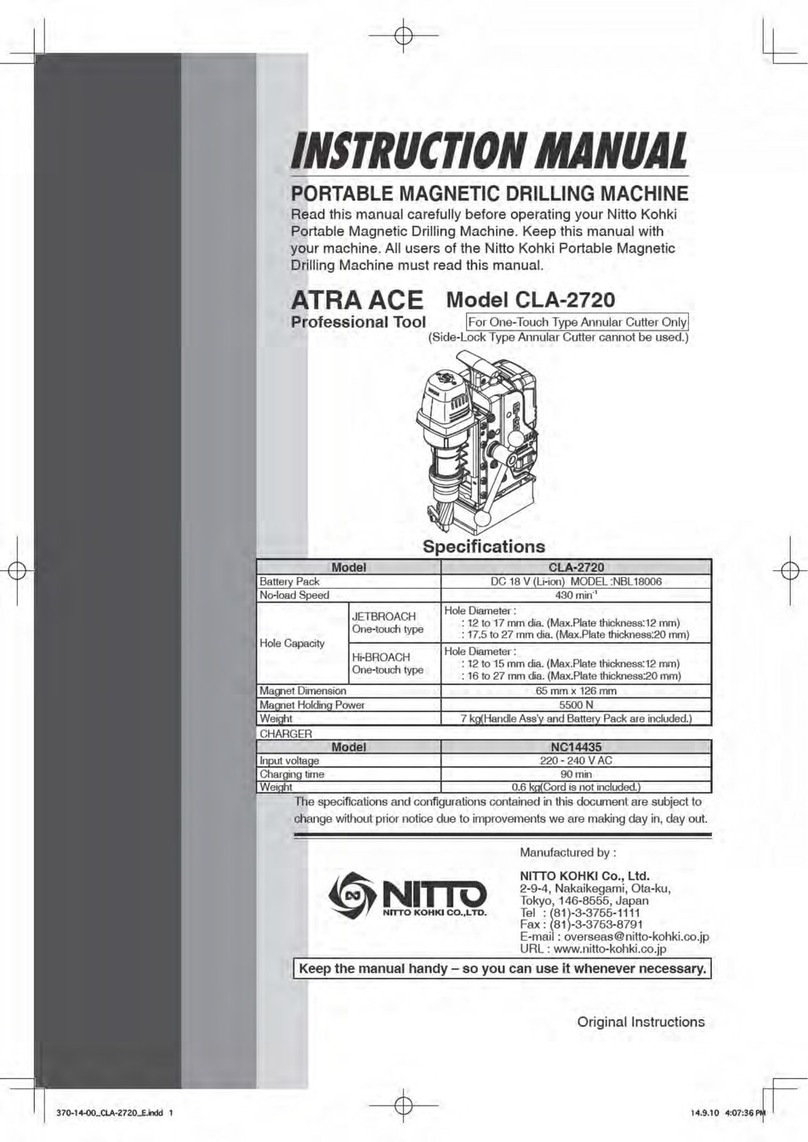

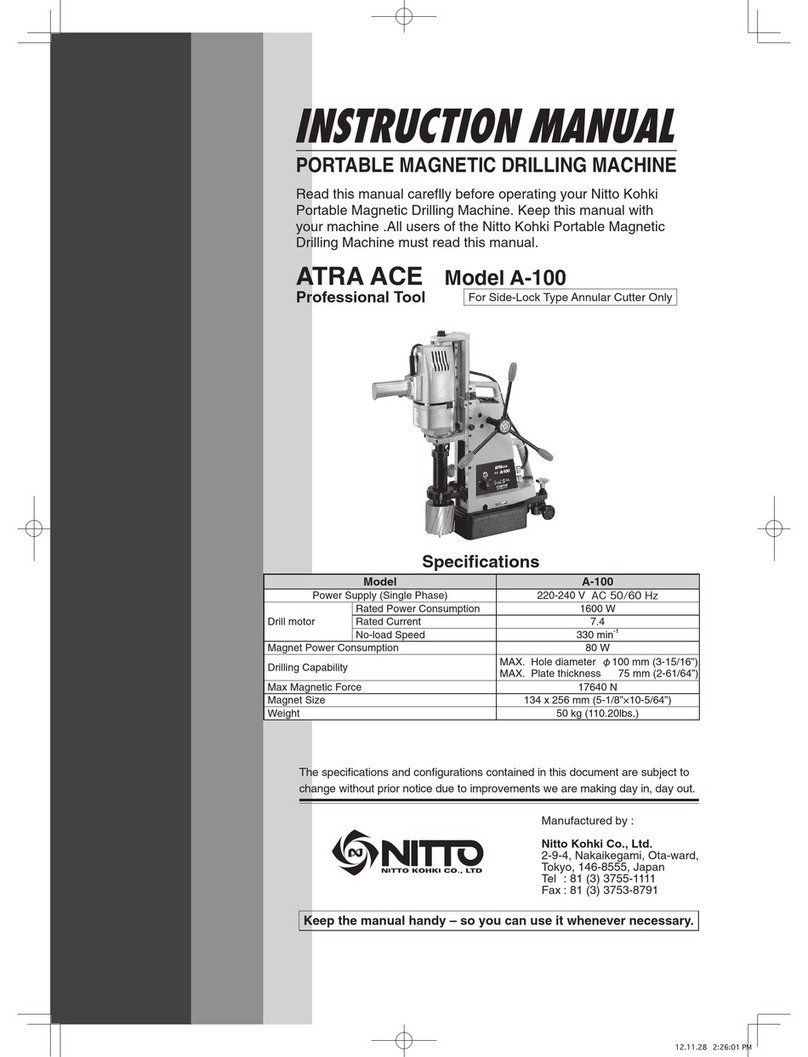

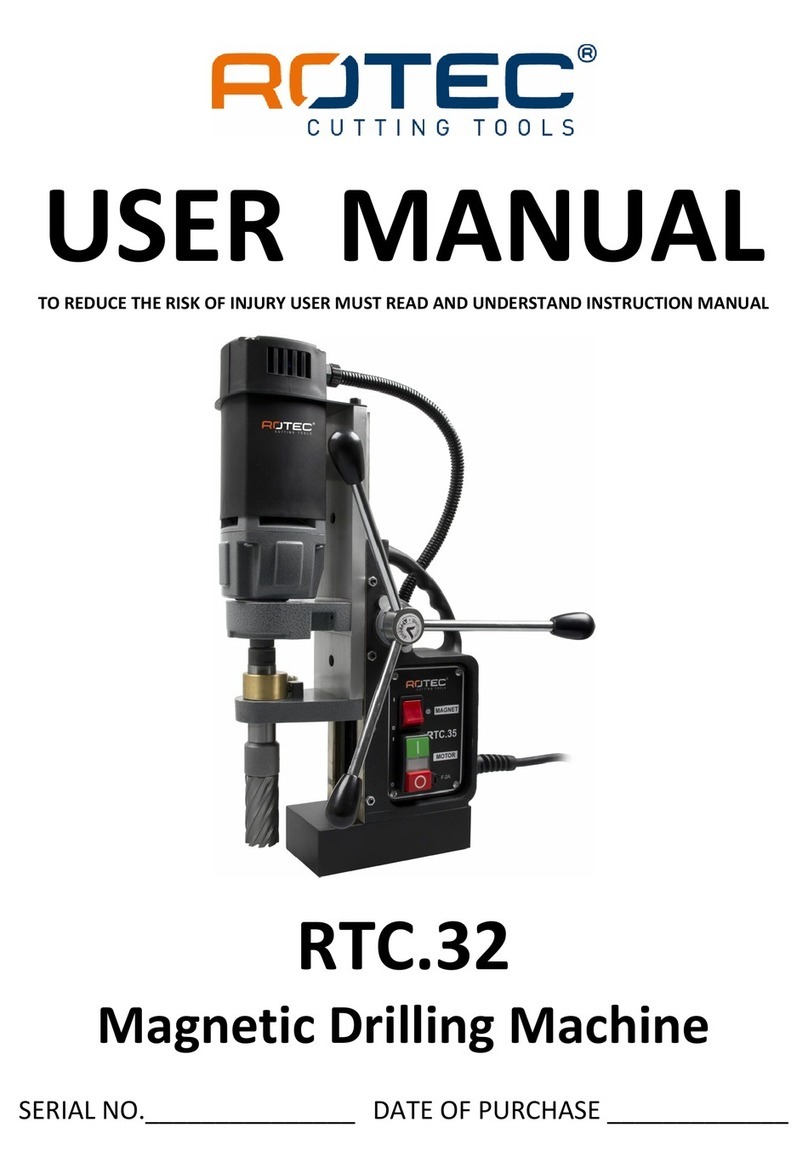

Nitto ADR-65 User manual

lJrFrrrraJ励

層JИ:

ALLINSTRUCT:ONS BEFORE OPERATING THiS TOOL

R DR:LL Modei ADRⅡ 65

ADRⅢ100

FESSiONAL T00L

SPECIFICAT10NS

and dos10n may be changed iorimprovement withoui pror nolice

Desioned&distr buted by

N!170 KOHК I CO"LTD

31h腑

雪

需鶏,

踏

半

°

1∬

湖

幌

ソ

露

1111

Fax: +81(0)337538701

1NSTRUCT10NS

ONIコ

濡

SAVE THESE

∞NTENTS

IMPORTANT SAFETY INSTRUCT10NS FOR ALL AIR TOOLS

IMPORTANTINSTRUCT10NS FOR AIR DRILL

l USACE 3

2 CHECK THE CONTENTS OFTHE PACKACE 3

3 AIR SUPPLY 3

4 1MPORTANTINSTRUCT10NS FOR AIR DRILL 3

5 HOVVTO OPERttE THE T00L 4

6 MAINTENANCE ANDINSPECT10N 4

8 0PT10NAL ACOESSORIES ……

‐

4

9 ADR‐65 ASSEMBLY AND PARTS LIST …………

…

Ⅲ …

5

10 ADR‐100 ASSEMBLY AND PARTS LIST ……………………………

6

△ 〇 ◎

7 0RDERING SERVICE P.qRTS

PiC● GRAPH

Warningi t mighi bO danOorous to operate tho powOriool

the nstruclions supplod are nol b‖owod

Bofore operatinO the too,「 ead and understand a‖

instructons supp1lod K●

●

p l 10r iuture relerence

Personal prolootV0 0qulpment as eyo and ear protedlon

and proloolVe gloves must always bo used when

operatin9 1he tool

△WARNING

When uslng a:r too:9, baslc sarety precautions

shou:d a:ways be fol:owed to reduce r:sk of

personaliniury,including the l●

‖

owings

Do noi let vis tors contact the too compressor or

conneclin9 hoses

(5)Some tOO19 generate high noise leveis

Check to be sure thatthe use oイ

this tool coniorms

to al local noise reoulat ons

(1)Be Sure a‖ ‐

external screws,nuts and bolis are

tightly secured priorio each use

(2)Do not use damaged, lrayed or deterlorated

hoses and flttlngs

(3)Remove adlustlng keys and wrenches

Form hab"。

i check nO to see that ad,usung keys

and wrenches are removed frOm tool before turning

ton

(4)uSe rlghi tool

Do notiorce a small。

。。

i attachmentio do the iob

ol a heavy‐duty tool

Do not use toollor a purpOse notintended

(5)Do notforce tool

‖wⅢ

do the lob bener and saler at the rate lor

、vhich it was desioned

(6)Sooure work

∪

s●clamps Or a vise to holo w。 「kpleces when

praclloal ltis salerthan usino your hand and lt(rees

both hands io operate tool

(7)Alr pressure at the ;ni● t must not exceed

0 59MPa(6kgf′ 。

m'′85PSl′ 5 0 bar)

When notin use,tools shou10 be stored in dr"and

locked‐

up places oui or reach of chiOren

(2)Avold unintentlonal starilng

Do not carry a r‐

powereO tool、v th iinger on throttle

VVhen carryinO too be sure the connect ng hose to

the compressoris disconnected

(3)Reduce the rlsk of unlntentlona!startlng

ヽИake sure thrOttle is in ・

OFF・ pos t10n belore

conneci no a r hose to tool

(4)Do not abuse hose

Never carry lool wlh a r sllpply hose connected or

yank On hose to disconnect

(5)NeVerleave tool runnlng unattended

Always turn oifthe a r supply and disconneclthe a r

supply hose Do not leave tool unattended untl i

comes to a complete stop

Operators ass19ned tO use the lools should be

instructed in the sare use Ofthe tool

No person should use this tool ヽv thout irst having

read and understood this instruct on manual

(1)●ress properly

Do nol、vearloose clothing or accessoi es They can

be caughtin moving paris

Non sk d lootwear s recommended

VVear protectvo ha r cover ng to contain lono ha r

(2)Always wear eye protectlon

Everyday eye。 lasses only have impact resislant

lenses They do NOT protecl eyes AIso use laco or

dust mask, l operat ons croat●dust

(3)Always wear protectlvo oar equlpmont

(4)Doい ot overreach

Keep prOperloot ng and balanoe at a‖ limes

(5)Stay alert

VVatch what you are dolng

use cOmmOn sense

Do nol operate tool when you are tred

(6)Some tOOIS generate substantia:vlbratlons

li discomlori or pain is encountered dur ng use,you

should cease operatons and che侠 w th yOur

physician pr or io lu「

ther use

(71 Be sure to koop hands clear off moving parts

(1)Keep wOrk are●

ciean

Cluitered work areas and benches invte accidents

and iniur es

12)Consider work area env:ronmeni

Do not expOse tools io rain Do nol ose tools in

damp or、vet locat ons

Keeps work area we‖ li

(3)Do not operate near flammable liqulds or ln

gaseous or explosive atmospheres

14)Keep ch‖

dren away

Also a‖

vis to「s should be kept away from 、vOrk

area

(1)StOre ldio tools

(2)Check damaged paris

Belore further use ofthe too an accessory or other

partthatis damaged should be carefuly checked lo

determine that ,l wil operate propery and perorm

ts intended Funct ons

Check lor a19nment of mOvinO parts, bindino oi

moving parts,breakage ol parts, mouning and any

other cond ilons thai may arrect ts Operal on

An accessory or olher part that is damageO or

inoperable should be proper y repa red or replace0

(3)Repalrs by author12ed personnel

Any repairs on the tool o「

instalal oo ol replacement

parts shou10 be periormed only by the sales agent

irom whom you purchased the tool or an author ze0

dealer use only genuine replacement parts

Falure to utize the experise oi the sales agent

irom、vいom you purchased the tool or an author zed

dealer or.lalure to use oenuine replacement parts,

may iesun an ncreased lsk oi niury to the user

and may lnvaldate your warranty

(4)uSe recOmmended accessories

Consu t this manual or the sales agent irOm

ヽVhom

you purchased the tool or an author zed dealer ior

recommended accessor es The use ol lmprOper

accessoles may cause nsk oi nlury to persons

(5)Always turn off the alr supply and dlsconnect

the alr supplyぃ。se before lnsta‖lng,removlng

or adlusting any accessory On the tool or

before performlng any malnlonance ollhe tool

(6)Do not removo anソ !abols or namepldes,rom

the tool

lf a label or nalmeplate has been damaged of is

missing cOntact the sales agent irom whom you

purchased the tool or an author zeO dealer io obtain

a replacement

3‐l Air Pressure

AI「

pressure largely Oetermines lool performance

This toolis desioned to be operated at a r pressure

of0 59 MPa(6k911cm2′ 85PS′ 5 9 bar)max mum

3‐

2 Air Line[F10 1]

Use a 95 mm (3′ 8') ar hOSe between the

compressor and the tool Compressed a r is cooled

and ts diain separated, as soon as the ar leaves

the compressor The drain, ho、 vever is condensed

in the plpin。

, and can enter the tool mechanism,

and may cause trouble So,instal an a rflter and an

oler betヽVeen the compressor and the tool

A,Fl er

Ar Re9JIol。

' 。ler

高

4ム

││

=48品

朧

s,

Toot r i「

IF0 1〕

Thls tool ls ior dr‖‖ng work

Tapplng (rlght‐hand screw)ls

uslng the reversible function

3‐3 Lubricatlon iFi0 1〕

An oler should bo insta‖ed betwoon the

compressor and the too Use mach no ol oSO VG

10) NeOlecing the ol supply wIl cause damaoe

Since tho use oi thlok 。

l w‖│ lead lo poor

periormance,a ways uso maCh no ol oSO VO■

0)

△WARNING

・

Wear prOtective glasses and earpiugs during

drilling Operation For the operation producing

much dust,wear an antidust mask

・

Wear cotton work gloves or vibration― proof

gloves tO prOtect your hands against vibrations

and chips

・

Nevertouch moving palts

・

When the dri‖ passes througぃ or locked during

drilling Or tapping,the main body may be swung

around lf it occurs,release the Trigger quickly

to avoid inlury Do not tap a b:ind hole using

this air drill

・

Do not use the exhaustfor air blow operation

△ CAUtt10N

・

For tapping,always use tapping paste

・

use sharp taps

・

use a tapertap(No l)and a plug tap(No 2)for

tapping

wnh a d ‖ b‖

a:so posslbl● by

Check the contents and make sure thatthe tool does

not have any damege due to an aceideni durnO the

transpOrtat on, f any The contenis should correspOnd

lo the accessor es on the parts lst Jusiin case there

are some damages or missing paris,contactthe sales

aOeni from 、vhom you purchased the tool or an

author zed dealer

3

5‐

l Moullting the Dr‖l Bit[F02]

△WARNING

・

Be sure to disconnect the air supplyい ose when

rep!acing the Dr‖l Bit

l ountthe dr‖lbito the Chuck,and ti9hten the ChuCk

securely w ih ihe accessory Chuck Handle

5‐2 Starting and Stopping the Air Dri‖

[F19 3〕

△WARNING

・

Never touch movlng parts

(1)COn

rm that the■goer is OFF and in the

connectno hOSe onto the Cupla plu9 on the A「

El「

11

(2)To turn On the A r D子11,hOld the A r D1l by hands

and pul the Trigger

(3)To turn

oll,re ease the予

。

ger

Chuok

5‐5 How To Change Rotation Direction[Fig 5]

Change rOtaton d recton by turning the valve as

indicated

5Tapping operation

(1)D1l a hole belore tappin。

△CAUT10N

・

Make the hoie as large as possible within the

tolerance for strength

(2)Apply tapping paste tO the tap

(3)Conlrm that the Valve is set ior nOrmal rotalon

d reclon IFig 51

(4)A10n the tap r.th the hole,and stari tappin。

lf the top end Of drll canool break into the hole

vvhen the tap diameteris lape manualy rotate the

drl in normal rotai no oirect on by several turns

ヽV th the■looer set on and then starttapping

(5)Aiter tappino ends, chanOe the rotaton d recton

and pu‖ out the tap 、vhle the dril is rotat n0

reversely

5‐3 How To Hold the Alr Dr‖

l[F10 4〕

For stable operaton hold the grp ol lhe A r Dr‖

l by

one hand、vth the middle iinger put on the予

│。

9er and

the index(inger extended overthe main bOdy,and orp

the main bOoy frmly 、vth the other hand as below

i gure

5‐4 HowTo Adlust Rotating speed[F0 51

Turn the SpeeO Control Nutio aOlustthe drl rotaung

speed Adlust the rOlatng speed fOr the operalon

requrement

△CAUTION

・

VVhen notln use,the tool should be stored in a

dry p!ace out olreach of ch‖dren

lF the toolis leit as it、vas used they、v1l keep moisture

insiOe ll This、vl1 0enerate rust VVhen a 10bイinishes,

ol them wh machne ol(ISO VG 10)and Operate t

lor a whle and then store it

ln order ng paris and components i「om the sales

agent from 、vhom you purchased the tool or an

author zed dealer Oive each part number pari name

and quantty requ red

A hangerto be mounted

avalable as opton

lt can be mOunted on both

on the bottom oithe Orp is

ADR 65 and ADR‑100

Vh∞ 、

雹躾吟

F04

[F10 6]

JJJrFrrrraJ‖

朋f

R[ADA[[INSTRUeT10NS BEFOR[OP[RA■ ING THIS T00[

AIR DRILL Model ADR‐ 65,ADR‐ 100 T(,110341)

Other manuals for ADR-65

1

This manual suits for next models

1

Other Nitto Drill manuals