Mower Land MLTILL5 User manual

MOWER LAND

Before operating this appliance, please ensure that you read & understand all

the instructions that apply to it, as failure to comply wih these instructions

may result in personal injury to other persons, and also increase the risk of

fire. Please ensure that any replacement parts or accessories used with this

appliance are correctly and/or securely fitted before use.

Please retain these instructions for constant reference.

OPERATOR' S MANUAL

MODEL MLTILL5

MOWER AND TILLERL

* Measured according to 2000/14/EC

* Measured according to EN1033:1995

2

2

TABLE OF CONTENTS

INTRODUCTION

Your new front tine tiller will more than satisfy

your expectations. It has been manufactured under

stringent quality standards to meet superior

performance criteria. You will find your new tiller

easy and safe to operate, and with proper care,

it will give you many years of dependable service.

Carefully read through this entire

operator’s manual before using your

new tiller. Take special care to heed

the cautions and warnings.

Your tiller has many features that will make your

job faster and easier. Safety, performance, and

dependability have been given to top priority in

the development of this machine, making it easy

to maintain and operate.

The Engine Manufacturer is responsible for all

engine-related issues with regards to performance,

power rating, specifications, warranty and service.

Please refer to the Engine Manual, packed

separately with your unit, for more information.

Introduction

Specifications

Symbols

Safety

General Safety Rules

Specific Safety Rules

Contents supplied

Assembly

Know your tiller

Features & Controls

Tiller Operation

Maintenance

Storage

Trouble Shooting

Parts Schedule

2Mowerland Tiller

ENVIRONMENTAL

Recycle unwanted materials instead of

disposing of them as waste. All tools,

hoses and packaging should be resorted,

taken to the local recycling center and

disposed of in an environmentally safe

way.

The rating plate on your machine may show

symbols. These represent important information

about the product or instructions on its use.

SYMBOLS

Specifications

B&S QUANTUM 60

500mm

250mm

120rpm

42.5kg

96 dB(A)

79.3 dB

Left: 4.10 m/s

Right: 3.68 m/s

Engine

Cultivating Width

Cultivating Depth

Tine Speed

Weight

Sound power level

Sound pressure level

Vibrating level on

handlebar grips

2

2

2

3

3

5

6

6

9

9

12

13

14

15

16

Wear eye protection.

Wear hearing protection.

Read these instructions for use carefully.

Wear safety footwear.

Wear safety gloves.

It is forbidden to remove or tamper with

the protection devices and safety devices.

Keep away from rotating tines. Rotating

tines will cause injury.

Do not touch a hot muffler, gear housing

or cylinder.

Do not smoke or have open flames.

Thrown objects.

Keep bystanders away.

EC declaration of conformity 17

SAFETY

Understand your machine

Use safety equipment. Always wear eye protection.

Safety equipment such as a dust mask, hard hat,

or hearing protection used for appropriate

conditions will reduce personal injuries.

General Safety Rules

Read and understand the operator’s manual and

labels affixed to the machine. Learn its application

and limitations as well as the specific potential

hazards peculiar to it.

Be thoroughly familiar with the controls and their

proper operation. Know how to stop the machine

and disengage the controls quickly.

Make sure to read and understand all the

instructions and safety precautions as outlined in

the Engine Manual, packed separately with your

unit. Do not attempt to operate the machine until

you fully understand how to properly operate and

maintain the Engine and how to avoid accidental

injuries and/or property damage.

Work area

Never start or run the engine inside a closed area.

The exhaust fumes are dangerous, containing

carbon monoxide, an odorless and deadly gas.

Operate this unit only in a well ventilated outdoor

area.

Never operate the machine without good visibility

or light.

Never operate the machine on a steep slope.

Personal safety

Do not operate the machine while under the

influence of drugs, alcohol, or any medication that

could affect your ability to use it properly.

Dress properly. Wear heavy long pants, boots and

gloves. Do not wear loose clothing, short pants,

jewelry of any kind. Secure long hair so it is above

shoulder level. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewelry

or long hair can be caught in moving parts.

Check your machine before starting it. Keep guards

in place and in working order. Make sure all nuts,

bolts, etc. are securely tightened.

Never operate the machine when it is in need of

repair or is in poor mechanical condition. Replace

damaged, missing or failed parts before using it.

Check for fuel leaks. Keep the machine in safe

working condition.

Never tamper with safety device. Check their

proper operation regularly.

Do not use the machine if the engine’s throttle

control does not turn it on or off. Any gasoline

powered machine that can not be controlled with

the engine throttle control is dangerous and must

be replaced.

Form a habit of checking to see that keys and

adjusting wrenches are removed from machine

area before starting it. A wrench or a key that is

left attached to a rotating part of the machine may

result in personal injury.

Stay alert, watch what you are doing and use

common sense when operating the machine.

Do not overreach. Do not operate the machine

while barefoot or when wearing sandals or similar

lightweight footwear. Wear protective footwear

that will protect your feet and improve your footing

on slippery surfaces. Keep proper footing and

balance at all times. This enables better control of

the machine in unexpected situations.

Avoid accidental starting. Be sure the engine’s

throttle control is off before transporting the

machine or performing any maintenance or service

on the unit. Transporting or performing

maintenance or service on a machine with its

throttle control on invites accidents.

Fuel safety

Fuel is highly flammable, and its vapors can explode

if ignited. Take precautions when using to reduce

the chance of serious personal injury.

When refilling or draining the fuel tank, use an

approved fuel storage container while in a clean,

well-ventilated outdoor area. Do not smoke, or

allow sparks, open flames or other sources of

ignition near the area while adding fuel or operating

the unit. Never fill fuel tank indoors.

Keep grounded conductive objects, such as tools,

away from exposed, live electrical parts and

connections to avoid sparking or arcing. These

events could ignite fumes or vapors.

3

Mowerland Tiller

Service

Keep the engine and muffler free of grass, leaves,

excessive grease or carbon build up to reduce the

chance of a fire hazard.

Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting edges

are less likely to bind and are easier to control.

Never douse or squirt the unit with water or any

other liquid. Keep handles dry, clean and free from

debris. Clean after each use.

Observe proper disposal laws and regulations for

gas, oil, etc. to protect the environment.

Store idle machine out of the reach of children

and do not allow persons unfamiliar with the

machine or these instructions to operate it. Machine

is dangerous in the hands of untrained users.

Before cleaning, repair, inspecting, or adjusting,

shut off the engine and make certain all moving

parts have stopped. Always make sure the engine’s

throttle control is in its “STOP” position. Disconnect

the spark plug wire, and keep the wire away from

the plug to prevent accidental starting.

Have your machine serviced by a qualified repair

personnel using only identical replacement parts.

This will ensure that the safety of the machine

maintained.

Never store fuel or machine with fuel in the tank

inside a building where fumes may reach an spark,

open flame, or any other source of ignition, such

as a water heater, furnace, clothes dryer and the

like. Allow the engine to cool before storing in any

enclosure.

Always stop the engine and allow it to cool before

filling the fuel tank. Never remove the cap of the

fuel tank or add fuel while the engine is running

or when the engine is hot. Do not operate the

machine with known leaks in the fuel system.

Loose the fuel tank cap slowly to relieve any

pressure in the tank.

Never over fill fuel tank. Fill tank to no more than

12.5mm (1/2”) below the bottom of the filler neck

to provide space for expansion as the heat of the

engine and/or sun cause fuel to expand.

Replace all fuel tank and container caps securely

and wipe up spilled fuel. Never operate the unit

without the fuel cap securely in place.

Avoid creating a source of ignition for spilled fuel.

If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of

spillage and avoid creating any source of ignition

until fuel vapors have dissipated.

Store fuel in containers specifically designed and

approved for this purpose.

Store fuel in a cool, well-ventilated area, safely

away from sparks, open flames or other sources

of ignition.

Machine use and care

Never pick up or carry a machine while the engine

is running.

Do not force the machine. Use the correct machine

for your application. The correct machine will do

the job better and safer at the rate for which it

was designed.

Do not change the engine governor settings or

over-speed the engine. The governor controls the

maximum safe operating speed of the engine.

Do not run the engine at high speed when you are

not tilling.

Do not put hands or feet near rotating parts.

Avoid contact with hot fuel, oil, exhaust fumes and

hot surfaces. Do not touch the engine or muffler.

These parts get extremely hot from operation.

They remain hot for a short time after you turn off

the unit. Allow the engine to cool before doing

maintenance or making adjustments.

If the machine should start to make an unusual

noise or vibration, immediately shut off the engine,

disconnect the spark plug wire, and check for the

cause. Unusual noise or vibration is generally

warning of trouble.

Use only attachments and accessories approved

by the manufacturer. Failure to do so can result

in personal injury.

Maintain the machine. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the machine’s

operation. If damaged, have the machine repaired

before use. Many accidents are caused by poorly

maintained equipment.

4Mowerland Tiller

Use caution when tilling near fences, buildings and

underground utilities. Rotating tines can cause

property damage or personal injury.

Exercise extreme caution when operating on or

crossing gravel drives, walks, or roads. Stay alert

for hidden hazards or traffic. Do not carry

passengers.

Never leave the operating position when the engine

is running.

Always stop the engine when tilling is delayed or

when walking from one tilling location to another.

Keep unit clean of vegetation and other materials.

They may become lodged between the tines. Stop

the engine and disconnect the spark plug before

unclogging the tines.

Keep all bystanders, children, and pets at least

23m (75 feet) away. If you are approached, stop

the unit immediately.

Specific Safety Rules

Thoroughly inspect the area to be tilled, and

remove all debris and hard or sharp objects such

as stones, sticks, glass, wire, bones, etc. Do not

operate tiller in soil with large rocks and foreign

objects which can damage the machine.

Do not till above underground electric cables,

telephone lines, water lines, gas lines, pipes, or

hoses. If in doubt, contact your utility or telephone

company to locate underground services.

This unit has a clutch. Squeeze the clutch control

lever and check that it returns automatically to

the neutral position. If it does not, have unit adjusted

by a qualified repair personnel.

Disengage clutch lever before starting the engine.

Start the engine carefully according to instructions

and with feet well away from the tines.

The tines remain stationary when the clutch is

disengaged. If it does not, have unit adjusted by

a qualified repair personnel.

Always operate the machine from behind, never

pass or stand in front of the machine when the

engine is running.

Always hold the unit with both hands when

operating. Keep a firm grip on the grips. Be aware

that the machine may unexpectedly bounce

upward or jump forward if the tines should strike

buried obstacles such as large stones, roots, or

stumps.

If the unit strikes a foreign object, stop the engine,

disconnect the spark plug, thoroughly inspect the

machine for any damage, and repair the damage

before restarting and operating the machine.

Use extreme caution when in reverse or pulling

the machine towards you.

Do not overload the machine capacity by tilling

too deep in a single pass or at too fast a rate.

Never operate the tiller at high transport speeds

on hard or slippery surfaces.

Be careful when tilling in hard ground. The tines

may catch in the ground and propel the tiller

forward. If this occurs, let go of the handlebars

and do not restrain the machine.

5

To reduce exposure to vibration, limit the hours

of operation and take periodic breaks to minimize

repetition and rest your hands. Reduce the speed

and force in which you do the repetitive movement.

Try to fill each day with jobs where operating

hand-held power equipment is not required.

Mowerland Tiller

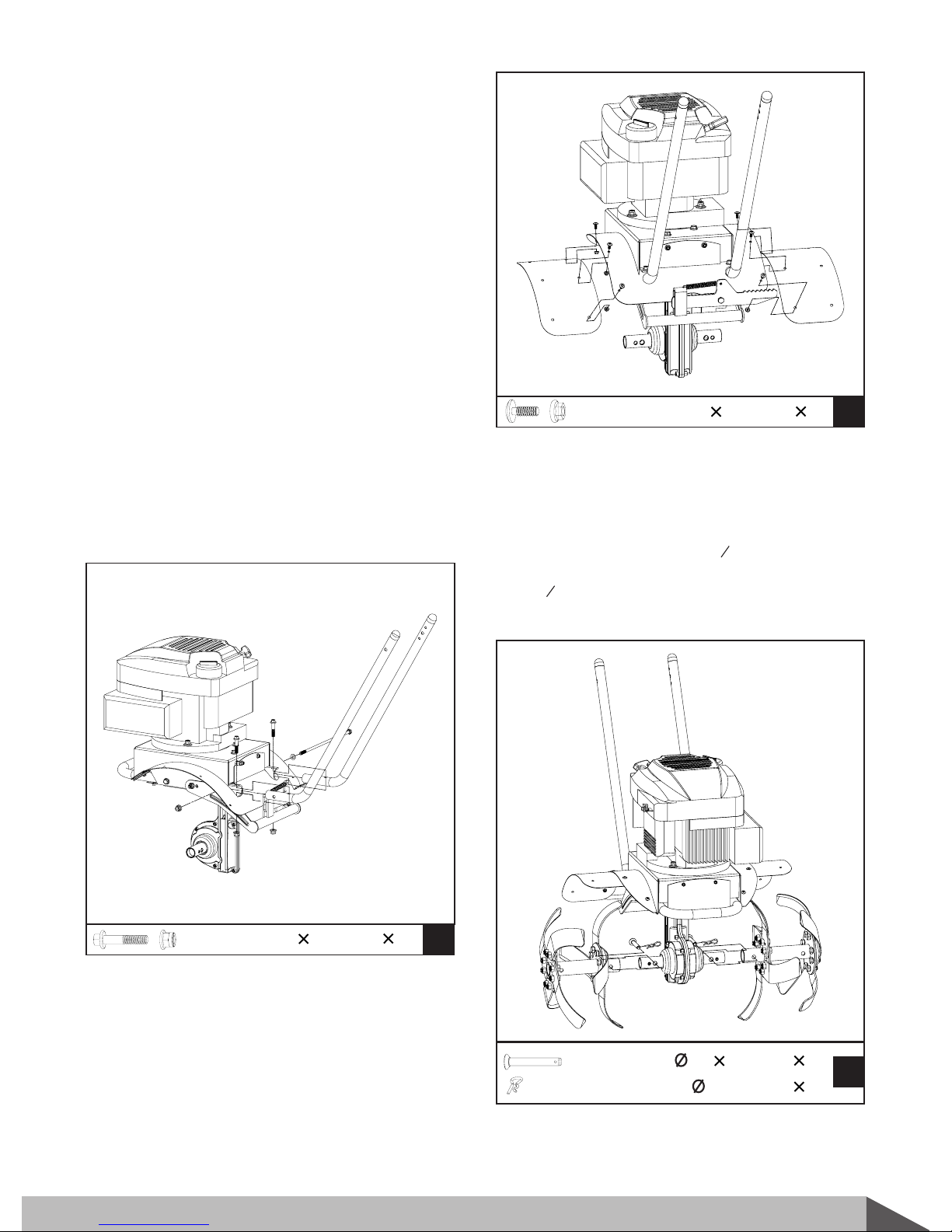

CONTENTS SUPPLIED

The front tine tiller comes partially assembled and is shipped in carefully packed carton. After all the

parts have been removed from the carton, you should have:

1. Tilling Tine (1 pair)

2. Wheel Support Bracket

3. Lower Handle – Right

4. Lower Handle – Left

5. Tiller Chassis with Engine and Transmission

6. Wheel Bracket Lock Block

7. Depth Regulator Rod

8. Upper Handle

9. Handle Adjustment Knob (1 pair)

10. Wheel Cover (1 pair)

11. Tine shield extension (1 pair)

12. Wheel (1 pair)

13. Operator’s Manual

14. Hardware Bag, including

ASSEMBLY

Wheels

Following the assembly directions below, you will

assemble the front tine tiller in a few minutes.

Slide the tube sleeve into the wheels. Mount the

wheels on both sides of the bracket with M10 flange

screws, washers and flange nuts. Attach the wheel

covers.

A

2M10 60

6

1

2 3 4 5

7

8

9

10

11

1412

13

6

2

6

2

M10 60

B

C

D

A

E

F

M8 45 2

M5 12

10 50

G

22.5

2

M10 20

3

14

Mowerland Tiller

Lower handles

Remove the M8X260 screw, flat washer and

lock nut from the rear end of tiller chassis.

1.

Mounting holes for adjustment knob are

arranged in the top portion of each lower handle.

Make sure the 3-hole side of the handle is facing

inward. Insert the bottom portions of the lower

handles into the mounting channels located in

the underside of each side of the tiller chassis.

2.

Mount the flat washer on the M8X260 screw

removed. Line up the holes in the bracket,

handles and tiller chassis. Slide the screw

through the holes from one side, then lock nut

from the other side. Leave them untightened

at this time.

3.

Tilling tines

Place tilling tines on the tine shaft on both sides

of the gear box. Line up the holes in the tine frame

sleeves and tine shaft. Insert O10X50 clevis pins

through the holes in tine frames and tine shaft.

Insert O2.5 cotter pins through the holes in the

clevis pins to secure them.

On each side, slide on a M8X45 flange screw

through the holes in the mounting channel and

the lower handle, then screw a flange nut.

4.

B

M8 45 2

Tine shield extensions

Attach the tine shield extensions to the tine shield

with M5X12 screws and flange nuts.

C

6M5 12

D

210 50

22.5

7

Tighten down all the screws.5.

Mowerland Tiller

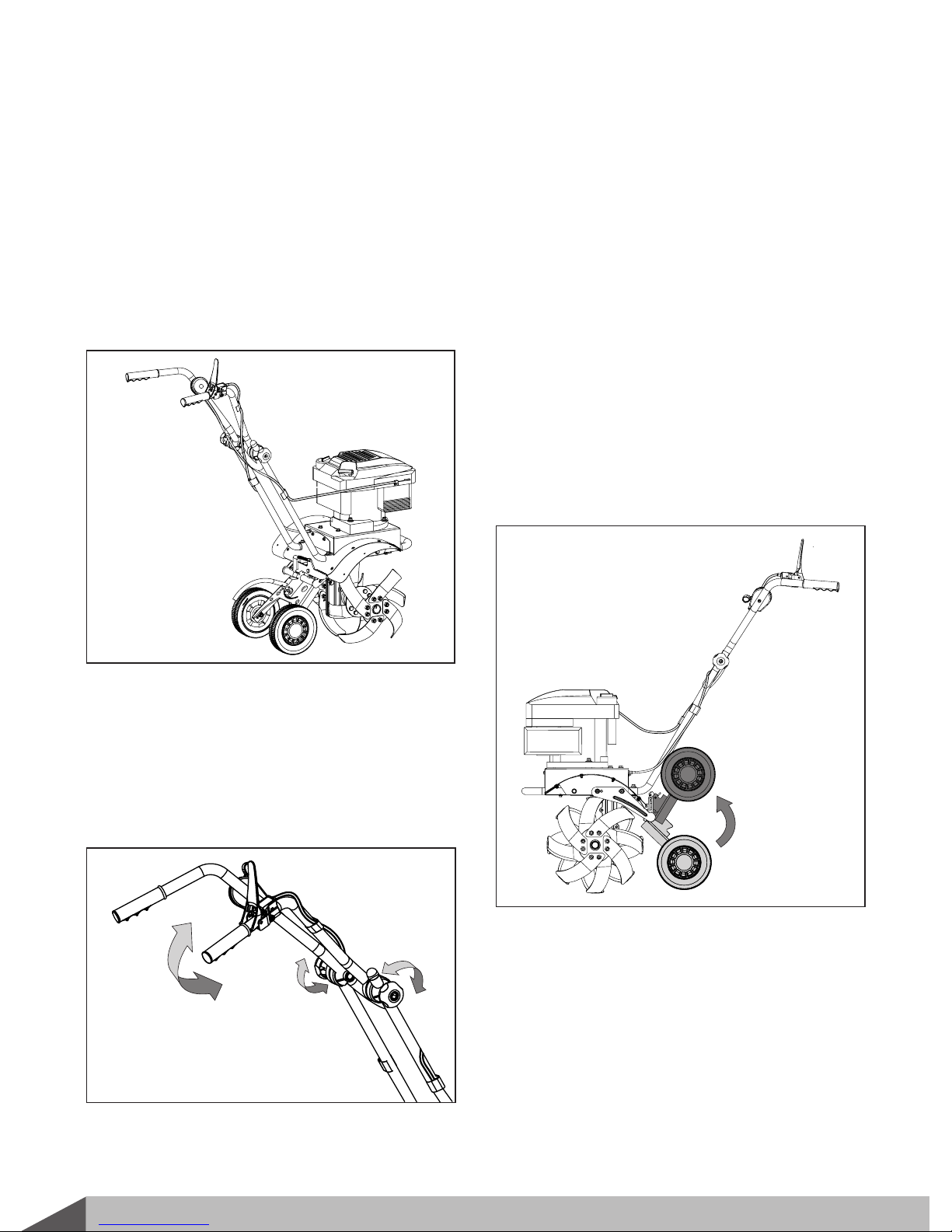

Depth regulator rod

Insert the depth regulator rod through hole in

the wheel bracket lock block from the top down

with curve to the rear of the unit and secure

with a O4 cotter pin through the holes in the

bracket lock block, passing through the desired

hole in the depth regulator rod.

Upper handle

Mount the upper handle on the lower handles

with the handle adjustment knobs.

2.

Disassemble the handle adjustment knobs.1.

Upper

Handle

Retainer

Cone

Bolt

Inside

Adjuster

Lower

Handle

Konb

Outside

Adjuster

Throttle & clutch controls

Remove the M6X60 carriage bolt and nut from

the throttle control assembly. Mount the throttle

control on the left side of the upper handle with

the hardware removed. Make sure the throttle

control is mounted outside the handle.

2.

Unwind the throttle control and clutch control

from around the engine. Straighten the cables.

Make sure that you do not bend or kink the

cables.

1.

Remove the M6X40 socket screw and nut from

the clutch control lever assembly. Mount the

clutch control lever on the right side of the

upper handle with the hardware removed. Make

sure the clutch control lever is mounted on the

top of the handle.

3.

Use two cable clips to secure the clutch control

cable and throttle control cable in place on the

lower handles. Attach the clutch control cable

to the upper handle with another cable clip.

Make sure the control cables are routed properly.

4.

F

Wheels bracket

E

2M10 20

3

8

Press down on the release pedal and insert the

lock block under the lock lever. Make sure the

spring-loaded lever locks in one of the grooves.

1.

Hook the wheel bracket on the tailpiece bracket

assembly.

2.

Secure the wheel bracket lock block on the

wheel bracket with two M10X20 screws and

teethed washers.

3.

Mowerland Tiller

Add oil according to Engine Manual packed

separately with your tiller.

Engine oil

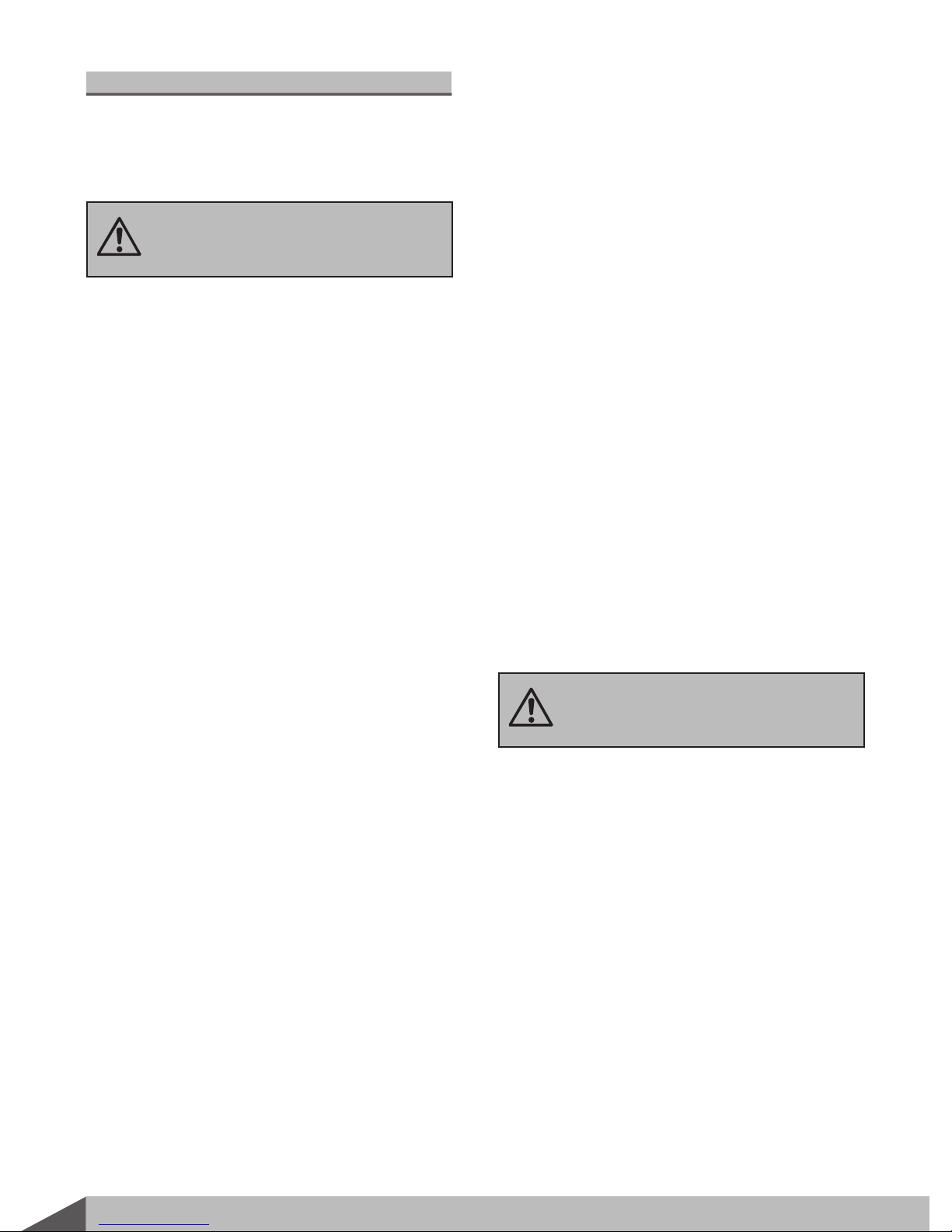

KNOW YOUR TILLER

Features and Controls

G

14

Engine is shipped from factory without

oil. You must add engine oil before

starting engine.

Upper Handle

Lower Handle

Depth Regulator Rod

Wheel Support Bracket

Wheel

Handle Adjustment Knob

Tine Clutch Control

Throttle Control Lever

Wheel Bracket Release Pedal

9

Mowerland Tiller

Handle adjustment knobs

Provides different handle heights for different tilling

conditions.

Loosen both handle adjustment knobs, and pivot

handle forward or backward to desired height,

then tighten the adjustment knobs securely.

Wheels bracket release pedal

The spring-loaded wheels bracket release pedal

locks wheels bracket with depth regulator rod

at different height and distance from the tines.

Press down on the wheels bracket release pedal

to release the wheels bracket. With the tines

touching the ground, an upward pressure on

the handles will fold the wheels bracket toward

the tines. With the wheels sitting on the ground,

a downward pressure on the handles will unfold

the wheels bracket away from the tines. Release

the pedal to lock the wheels bracket in the

desired position.

Throttle control

Controls the engine speed and stops the engine.

Tine clutch control

Pushing down to engage tines into forward.

Releasing returns machine to neutral.

Transport wheels

Set the wheels down and the depth regulator rod

with curve up when transporting the tiller. Tilt the

machine back until the tines clear the ground. Push

or pull the unit to the next location.

The unfolding and flexible wheels bracket with

depth regulator rod gives the tiller its versatility

and its stability. When the wheels bracket is

unfolded for tilling, the long length between the

tines and depth regulator rod provides more

comfortable operation.

10 Mowerland Tiller

Depth regulator rod

Serves a dual purpose. It regulates the tilling depth

and helps the operator control the direction and

speed of the tiller.

Unfold the wheels bracket to raise the wheels to

one of the high positions. Set the depth regulator

rod with curve down to the rear of the unit.

1. Remove the cotter pin.

Raise or lower the depth regulator rod.2.

Align groove in depth regulator rod with the

holes in bracket lock block and replace the cotter

pin.

3.

Lowering the depth regulator rod will slow the

tiller and make it till deeper. Raising the depth

regulator rod will allow it to move faster and till

more shallow.

To adjust the tilling depth.

For heavy soil (100mm / 4” depth or greater),

remove the depth regulator rod and work the tines

down with a back and forth motion to at least a

depth of 100mm (4”). Slowly pull the tiller backward

allowing the soil to feed forward over the tines.

Do not adjust tilling depth unless tine

clutch control lever is released to the

neutral position.

Besides obtained from the wheels bracket

adjustment, the depth regulator rod can be

adjusted through its grooves.

11

Mowerland Tiller

Tiller Operation

Adding fuel

Fill the fuel tank as instructed in the separate

Engine Manual packed with the tiller.

Starting engine

The controls required to start and run the tiller are

located on the engine and are marked “CHOKE”

and “THROTTLE”. Throttle can be adjusted by the

throttle control lever mounted on the left upper

handle through a control cable.

A more detailed description of the engine operation

and all related precautions and procedures can be

found in the Engine Manual packed separately

with the tiller.

Follow the procedure below for cold starts:

1. Turn choke lever on the engine to full choke

position.

2. Set the throttle lever to “FAST” position.

3. Pull the starting rope slowly several times to

allow the gasoline to flow into the engine’s

carburetor. Then hold the start handle firmly

and pull rope out a short distance, until you feel

some resistance. Then pull the rope smoothly

and briskly, and allow rope to return gently. Do

not let the rope to snap back. If necessary, pull

the rope several times until the engine starts.

4. Allow the engine to run for several seconds to

warm up. Then, gradually move chock lever to

no choke position and adjust the throttle control

to desired speed.

5. Grip the handles firmly with both hands. Squeeze

down on the clutch control lever - this will

engage the tines and move the filler in a forward

direction.

Restarting an engine that is already warm from

previous running does not normally require use of

the choke.

1. Move throttle lever to “FAST” position.

2. Hold the start handle firmly and pull rope out

a short distance, until you feel some resistance.

Then pull the rope smoothly and briskly, and

allow rope to return gently. Do not let the rope

to snap back.

3. Adjust the throttle control to desired speed.

4. Grip the handles firmly with both hands. Squeeze

down on the clutch control lever to engage the

tine and move the filler in a forward direction.

Idle speed

Set throttle control lever to its “LOW” position to

reduce stress on the engine when tilling is not

being performed. Lowering the engine speed to

idle the engine will help extend the life of the

engine, as well as conserve fuel and reduce the

noise level of the machine.

Shutting down

1. Release tine clutch control lever to neutral

position to stop the tines.

2. Set throttle control lever to its “STOP” position

to stop the engine.

Operating speed

For normal tilling, set the throttle control lever to

“FAST” for best tiller action. The throttle should

be set to control forward movement to a slow

walking speed for cultivating. Set the throttle

control lever to “LOW” to reduce stress on the

engine when tilling is not being performed.

Besides depth regulator rod setting, variation of

pressure on the handles also helps further control

of tilling depth and travel speed. A downward

pressure on the handles will reduce the tilling depth

and increase the forward speed. An upward

pressure on the handles will increase the working

depth and reduce the forward speed.

Fill tank to no more than 12.5mm (1/2”)

below the bottom of the filler neck to

provide space for expansion.

Starting engine

Do not move choke control to CHOKE

to stop engine. Backfire or engine

damage may occur.

12 Mowerland Tiller

Tilling

Tilling is digging in, turning over and breaking up

garden soil and prepare a seedbed for planting.

Best tilling depth is 100mm (4”) to 150mm (6”). A

tiller will also clear the soil of unwanted vegetation.

The decomposition of this vegetation matter

enriches the soil.

Avoid tilling soil that is too dry as it will pulverize

and produce a dust that will not hold water. Water

a few days before tilling. Also, tilling soil that is

too wet will produce unsatisfactory clods. Wait a

day or two after heavy rain for the soil to dry.

Better growth will be obtained if an area is tilled

properly and used soon after tilling to preserve

the moisture content.

The type of soil and working conditions will

determine the actual setting of the tilling depth.

In some soils, the desired depth is reached first

pass over garden. In other soils, the desired depth

is obtained by going over the garden two or three

times. In later case, the depth regulator rod should

be lowered before each succeeding pass over the

garden. Passes should be made across the length

and width of the garden alternately. Do not try to

dig too deeply in the first pass. If the machine

jumps or bucks, allow the unit to move forward

at a lightly faster rate.

If the tiller stops forward motion and tries to dig

in one spot, rock the handles from side to side to

start it moving forward again.

Rocks which are turned up should be removed

from the garden area.

Cultivating

Cultivating is loosening or digging around growing

plants to disrupt weeds and aerate soil. Less than

50mm (2”) depth is always desirable.

MAINTENANCE

Cleaning tine area

Keeping your tiller in top running condition will

prolong its life, and help you obtain optimum

performance whenever you wish to till your garden.

1. Turn off engine. Engine must be cool.

Clean the tiller underside of the tine shield after

each use. The dirt washes off tines easier if rinsed

off immediately instead of after it dries.

2. Keep the engine’s throttle control in its “STOP”

position, and remove spark plug wire from spark

plug and secure.

3. Remove all vegetation, string, wire, and other

materials that may have accumulated to the

axle between the inside set of tines and the

seals on the transmission housing.

4. Always towel dry the tiller afterwards and apply

a light coat of oil or silicone to prevent rusting

or water damage.

5. Replace spark plug wire.

Lubrication

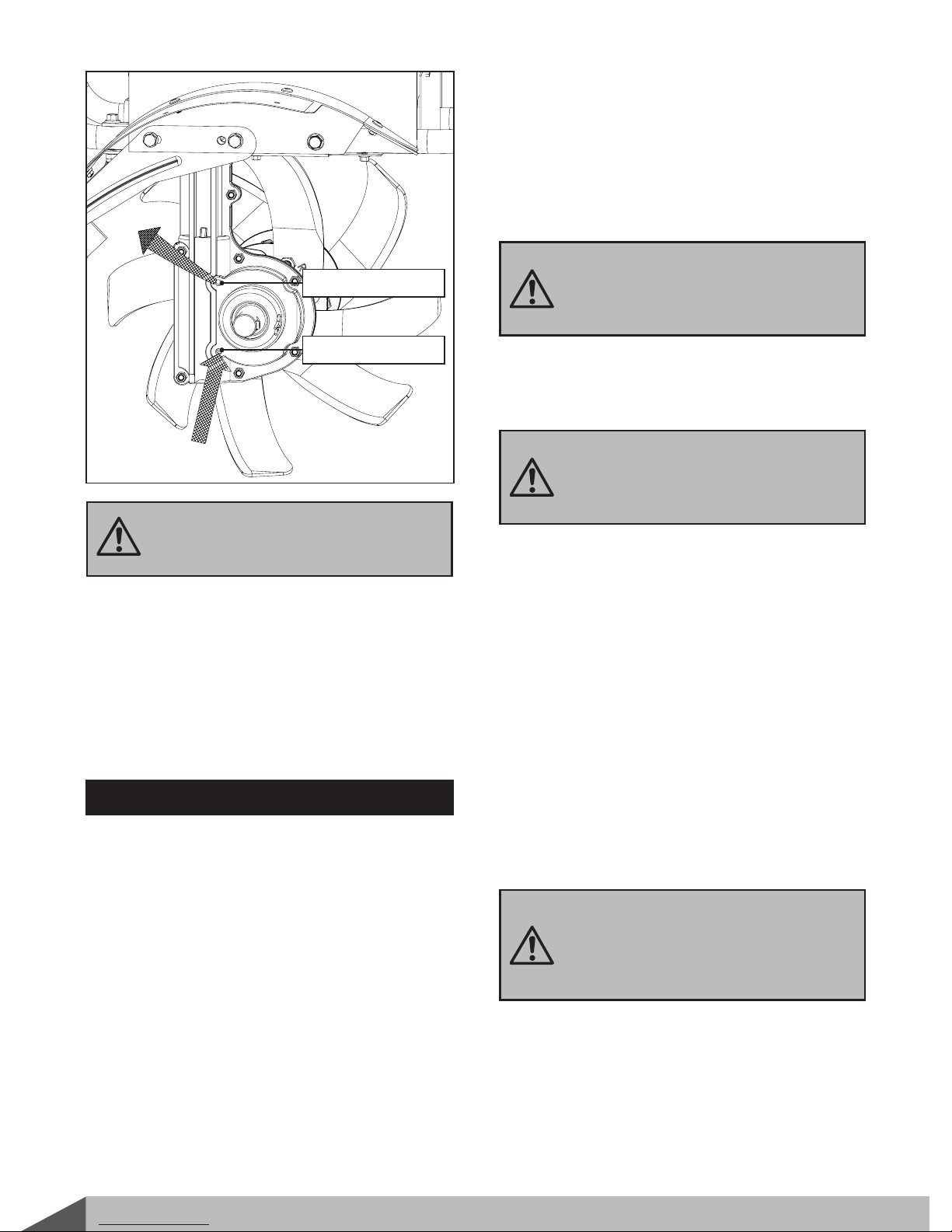

Remove the tine assemblies to lubricate the tine

shafts at least once a season.

The worm gear housing is pre-lubricated and

sealed at the factory. At the beginning of each

season, make sure enough lubricant inside the

worm gear housing. Use portable tool lithium #0

grease such as Lubriplate 6300AA , Lubriplate

GR-132, or Multifak, e.g. EP-O.

1. Remove right side tines and place the tiller on

level surface.

Allow the transmission to cool before filling with

grease.

2. Remove the grease fitting screw and air vent

screw to fill the worm gear housing through the

lower grease fitting hole until the grease begins

to come out from the upper air vent hole.

3. Reinstall the grease fitting screw and air vent

screw.

Never use a “pressure washer” to clean

your tiller. Water can penetrate tight

areas of the tiller and its transmission

case and cause damage to spindles,

pulleys, bearings, or the engine. The

use of pressure washers will result in

shortened life and reduce serviceability.

13

Mowerland Tiller

1. Drain the fuel tank completely. Stored fuel

containing ethanol or MTBE can start to go stale

in 30 days. Stale fuel has a high gum content

and can clog the carburetor and restrict fuel

flow.

2. Start the engine and allow it to run until it stops.

This ensures no fuel is left in the carburetor.

This helps prevent gum deposits from forming

inside the carburetor and possible engine

damage.

3. While the engine is still warm, drain the oil from

the engine. Refill with fresh oil of the grade

recommended in the Engine Manual.

4. Allow the engine to cool. Remove the spark

plug and put 30 ml (1 oz.) of high quality motor

oil into the cylinder. Pull the starter rope slowly

to distribute the oil. Replace the spark plug.

STORAGE

If the tiller will not be used for a period longer than

30 days, following the steps below to prepare your

tiller for storage.

5. Use clean cloths to clean off the outside of the

tiller and to keep the air vents free of

obstructions.

6. Inspect for any loose or damaged parts. Repair

or replace damaged parts and tighten loose

screws, nuts or bolts.

7. Remove the tines. Clean and apply oil to the

tines and tine shafts to prevent rusting. Mount

the tines onto the tine shafts.

8. Oil the control cables and all visible moving

parts. Do not remove the engine cover.

9. To store with the handles folded down, loosen

the knobs that secure the upper handle to the

lower handles. Carefully fold the upper handle

down. Do not allow control cables to become

pinched or bent. Tighten the knobs.

Refer to the Engine Manual included in your tiller

for the information on engine maintenance. Your

Engine Manual provides detailed information and

a maintenance schedule for performing the

maintenance.

Engine maintenance

Air Went Screw

Grease Fitting Screw

Do not overfill. Too much grease can

create pressure which could damage

seals.

Remove the spark plug and drain all

of the oil from the cylinder before

attempting to start the unit after

storage.

Do not use strong detergents or

petroleum based cleaners when

cleaning plastic parts. Chemicals can

damage plastics.

Do not sore tiller with fuel in a non-

ventilated area where fuel fumes may

reach flame, sparks, or any ignition

sources.

Use only approved fuel containers.

14 Mowerland Tiller

Problem Cause Remedy

Engine fails to

start.

1. Spark plug wire disconnected.

2. Out of fuel or stale fuel.

3. Throttle control lever not in correct

starting position.

4. Choke not in ON Position.

5. Blocked fuel line.

6. Fouled spark plug.

7. Engine flooding.

8. Tine clutch control not in neutral

position.

1. Attach spark plug wire securely to

spark plug.

2. Fill with clean, fresh gasoline.

3. Move throttle control lever to start

position.

4. Chock must be positioned at CHOKE

for a cold start.

5. Clean the fuel line.

6. Clean, adjust gap, or replace.

7. Wait a few minutes to restart, but do

not prime.

8. Tine clutch control lever must be

released to neutral to start the engine.

Engine runs

erratically.

1. Spark plug wire loose.

2. Unit running on CHOKE.

3. Blocked fuel line or stale fuel.

4. Vent plugged.

5. Water or dirt in fuel system.

6. Dirty air cleaner.

7. Improper carburetor adjustment.

1. Connect and tighten spark plug wire.

2. Move choke lever to OFF.

3. Clean fuel line. Fill tank with clean,

fresh gasoline.

4. Clear vent.

5. Drain fuel tank. Refill with fresh fuel.

6. Clean or replace air cleaner.

7. Refer to Engine Manual.

Engine overheats.

1. Engine oil level low.

2. Dirty air cleaner.

3. Air flow restricted.

4. Carburetor not adjusted properly.

1. Fill crankcase with proper oil.

2. Clean air cleaner.

3. Remove blower housing and clean.

4. Refer to Engine Manual.

Engine will not

stop when throttle

control is positioned

at stop, or engine

speed does not

increase properly

when throttle

control is adjusted.

1. Debris interfering with throttle linkage.

2. Improper throttle linkage adjustment.

1. Clean dirt and debris.

2. Refer to Engine Manual to check and

adjust throttle linkage.

Tiller moves forward

during starting. Tine clutch control not in neutral position. Tine clutch control lever must be released

to neutral to start the engine.

Tiller is difficult to

control when tilling

(machine jumps or

lurches forward).

1. Improper tilling depth setting.

2. Too high engine speed on hard ground.

1. Raise the tines for shallower tilling by

raising the depth regulator rod.

2. Set the throttle lever at lower speed.

Tines do not engage.

1. Foreign object lodged in tines.

2. Tine clevis pin(s) missing.

3. Belt worn and/or stretched.

4.Pulley and idler not in correct

adjustment.

1. Stop tiller completely, check and

discard foreign object.

2. Replace tine clevis pin(s).

3. Replace belt.

4. Contact dealer.

326400000M110

TROUBLE SHOOTING

15

Mowerland Tiller

PARTS SCHEDULE

16 Mowerland Tiller

Spares and Helpline 01793 333220

EC DECLARATION OF

CONFORMITY

Declaration of conformity

Pursuant to the regulations of the following EC

Directives:

- Machinery Directive 98/37/EC

Handy hereby declares that the product

Machine type: Mowerland Tiller

Machine model: MLTILL5

Conforms to the main safety requirements of the

EC Directives listed above.

This conformity is based on the following standards

and normative documents:

EN 709:1997+A1

EN ISO3744:1995

The responsible person, based within the EC, is

identified below

Name: Mr. Derek Belcher

Title: Managing Director

Company: Handy Distribution

Address: Hobley Drive, Stratton St Margaret,

Swindon, Wiltshire, SN3 4NS

Signature : Date: 8 th June 2007

17

ISO11094:1991

Mowerland Tiller

Table of contents

Popular Tiller manuals by other brands

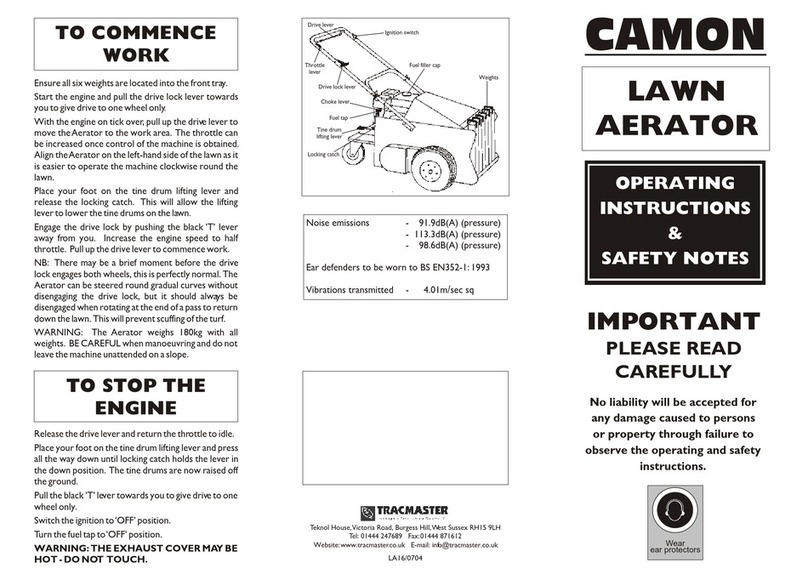

Camon

Camon G11302 Operating instructions & safety notes

Wiedenmann

Wiedenmann Greens Terra Spike G6/135 operating instructions

White Outdoor Products

White Outdoor Products ROTO BOSS 310 instruction manual

Scheppach

Scheppach MTE450 Translation from the original instruction manual

Mantis

Mantis Tiller/Cultivator owner's manual

POTILA

POTILA MAGNUM PLUS Series operating instructions