Mowin LIWIN L25 User manual

Manuale di istruzioni per l’uso

ISTRUCTION MANUAL

MODE D’EMPLOI

BEDIENUNGSANLEITUNG

MANUAL DE INSTRUCCIONES

Инструкция по монтажу

3

ENGLISH

1.1 Introduction to this manual

Please read carefully and follow the instructions detailed in this manual. Keep the manual for use and future

maintenance. Pay attention to the configuration of the DIP-switches, to the data concerning the performance (see

“Technical Data”) and to the installation instructions. Improper use or incorrect operation, fitting or assembly can

damage the system as well as cause injury to people and damage to property.

The assembling instructions are available on the official web site

http://www.comunello.com/mowin

2. SAFETY

This installation manual is written exclusively for competent professional personnel.

The installation, electrical connections and adjustments must be carried out conforming to good practice and

according to the regulations in force. Incorrect installation can cause a potential hazard. The packing materials

(plastic, polystyrene, etc.) must not be allowed to pollute the environment, but must be disposed of correctly, and

must not be left within the reach of children since they can cause possible hazards. Before starting installation,

check the product is complete and undamaged.

If the power cable is damaged, it must be replaced by the manufacturer or his technical support or a similarly

qualified person in order to avoid any risks.

Do not install the product in an explosive environment or atmosphere: the presence of flammable gas or fumes

is a serious health and safety hazard.

Before installing the drive mechanism, put in place all the structural modifications relating to safety measures

and to the protection or segregation of all the zones involving hazards of crushing, shearing, entrapment and of

general hazard. Check that all the existing structure has the necessary requirements of strength and stability. The

manufacturer of the drive mechanism is not responsible for failing to conform to good practice in the construction

of the windows to be opened, as well as any distortion which could occur during use.

Put up the notices laid down by current regulations to identify hazardous areas.

Ensure that the electrical supply is not a temporary one, but has the required electrical boxes, and in case of

doubt or lack of (definite) information, also install:

- suitable isolating transformers;

- thermal magnetic cut-outs suitable to voltage requirements;

- surge arrester.

Before connecting the electrical supply, ensure that the electrical rating correspond to that of electrical

distribution supply. Fit onto the supply network an allpole switch with a contact gap of at least 3 mm.

1. GENERAL INFORMATION

4

Check that on the supply side of the electrical plant there is a suitable differential residual current circuit breaker

and overload protection.

When required to do so, connect to an efficient earthing/ground system fitted according to the safety regulations

in force in the country where the actuator is being installed. Before carrying out any operation (installation,

maintenance or repair), isolate the electrical supply before working on the equipment. To ensure complete

isolation from the supply current, installation is recommended of a double-pole switch of the approved type. The

low-voltage 24 Vdc actuators must be supplied by suitable power supplies (NOT TRANSFORMERS) of an approved

Class II type (double safety insulation) having an output voltage of 24 Vdc -15% to +20% (or from 20.4 Vdc min. to

28.8 Vdc max.) When using the 24 Vdc version, the cable must have a suitable cross-section, calculated based on

the distance between the power supply and the actuator, so as not to have a voltage drop or loss.

The device is not intended to be used by people (including children) whose physical, sensory or mental capabili-

ties are reduced or by people who lack in experience or knowledge, unless a person responsible for their safety

can control them or give them instructions concerning the use of the device. Children must be supervised to

ensure that they do not play with the device.

The Liwin chain actuator is intended only and exclusively for use for which it was designed, and the manufacturer

cannot be held responsible for damage due to its improper use. The actuator is intended exclusively for internal

installation to open top-hung and bottom-hung windows, skylights, dormer windows and roof windows. Any other

use is not recommended unless with the prior approval of the manufacturer. Install the actuator according to the

instructions shown in this manual.

Any apparatus serving and controlling the actuator must be produced according to the regulations in force and

respect the relevant standards issued by the European Community.

If the actuator is installed on a window at a height of less than 2.5 m from the floor and in buildings (public and

otherwise) in which the use of destination is not clear, it must be operated exclusively by a command which is not

accessible by public (key button).

The command button has to:

1) be placed at a height of 1500 mm from the floor

2) be positioned so that, at its activation, a person who carries the opening and closing has within its field of view

all the moving parts.

Do not wash the apparatus with solvents or jets of water. Do not immerse the apparatus in water.

Any repair must be carried out by qualified personnel (the manufacturer or an authorised service centre).

Always insist that only original spare parts are used.

Failure to use the original spare parts could compromise the correct operation of the product and the safety of

people or property, also annulling the effects of the guarantee enclosed with the apparatus.

In case of any problems or doubt, contact the point of sale where the product was purchased or the manufacturer

directly.

Cross section of cables Max length of the cable

1,50 mm2~ 100 m

0,75 mm2~ 50 m

5

ENGLISH

3.1 Table of technical data and mark

The CE mark certifies that the actuator conforms to the essential health and safety requirements laid down

by European product directives. The CE mark can be identified by the relevant adhesive label applied to the

outside of the product, on which are shown some of the data shown in the following table:

3. TECHNICAL DATA

Liwin

Liwin 2W-Net

Liwin 3W-Net

Liwin 4W-Net

Liwin R

Liwin 2W-Net R

Liwin 3W-Net R

Liwin 4W-Net R

Model L35 230Vac ML35S140Hy00* ML35Sx40Hy00** ML35R140Hy00* ML35Rx40Hy00**

Model L35 24Vdc ML35S140Ly00* ML35Sx40Ly00** - -

Model L25 230Vac ML25S138Hy00* - - -

Power supply ac voltage 230 Vac 230 Vac 230 Vac 230 Vac

Power supply dc voltage 24 Vdc 24 Vdc - -

Frequency of ac voltage 50 Hz 50 Hz 50 Hz 50 Hz

Operation S2 4 min

Push/Pull strength L35 350 N 350 N 350 N 350 N

Push/Pull strength L25 250 N - - -

Stroke speed unloaded 18 mm/s

Protection class IP44

Double insulation ac yes

Double insulation dc low voltage

Motor voltage V ac L35 0,19 A 0,19 A 0,19 A 0,19 A

Motor voltage V ac L25 0,14 A - - -

Motor voltage V dc 1 A 1 A - -

Power L35 28 W 28 W 28 W 28 W

Power L25 22 W - - -

Operating temperature -5 / +50 °C

Strokes L35 50 – 100 – 150 – 200 – 250 – 300 – 350 – 400 – 420 mm

Strokes L25 200 – 250 – 380 mm

Closed limit switch on impact

Soft Start/Soft Stop yes / yes yes / yes yes / yes yes / yes

Obstacle detection yes yes yes yes

Connection in parallel yes ( max 30 actuators )

Synchronisation no yes no yes

Dimensions 390x38x73 mm

* Replace “y” with the colour code: 0B black, 0W white, 0G grey.

** Replace “x” with synchronisation value: 2 = two actuators, 3 = three actuators, 4 = four actuators.

6

4.1 Types of power supply

The Liwin series of actuators is available in various models and colours in two electrical supply versions:

• 230 Vac - can be supplied with mains power 230 Vac (50 Hz) (with a tolerance of ±10%), with a three-core

supply cable: BLUE, neutral common; BLACK, open phase; BROWN, closed phase.

• 24 Vdc - can be supplied with a voltage of 24 Vdc with a two-core supply cable: BLUE, connected to the +

(positive) closed; BROWN, connected to the + (positive) open.

4.2 Calculation of the force necessary

The calculation is made without considering the loads due to atmospheric agents.

Key to symbols F = Force required to open in N (Newton)

P = Weight of the window (only moveable part) in kg (kilogrammes)

C = Opening travel of actuator in cm (centimetres)

H = Height of the openable part of the window in cm (centimetres)

4.3 Pack and tools required for assembling the actuator

The actuator is packed individually in a cardboard box. Each pack contains:

electric actuator, 230 Vac 50 Hz or 24 Vdc, with electric supply cable, support brackets, fixing bracket for

top-hung window, fixing bracket for bottom-hung window, drilling template and instruction manual.

Before starting to fit the actuator, we recommend preparing the following fitting materials, tools and

equipment: Metre rule or tape measure, pencil, drill/screwdriver, set of drill bits for metal or wood, set of screw

bits, electrical pliers, screwdrivers, screws and/or threaded inserts suitable for the type of window material.

AVOID using self-tapping screws and/or three-lobed screws on any metal windows.

Bottom-hung inward opening Top-hung outward opening Horizontal skylight

P

P

F

F

C

(B)

P

F

C

(A)

H

H

P

P

F

F

C

(B)

P

F

C

(A)

H

H

P

P

F

F

C

(B)

P

F

C

(A)

H

H

F = [(P / 2 ) x (C/H)] x 9.8 F = [(P / 2 ) x (C/H)] x 9.8 F = (P / 2) x 9.8

4. ACTUATOR

7

ENGLISH

With bottom-hung windows, there is a danger of potential injury resulting from the window

accidentally falling.

It is OBLIGATORY to fit limiting arms (of the Series 1276 type), or an alternative safety system, of a

suitable size to prevent the window from accidentally falling down.

5.1 Installation sequence

- Check that the width of the window, where the actuator is due to be fitted, is more than 420 mm. Otherwise,

it is NOT POSSIBLE to fit the actuator.

- Check that the force required to open/close it (calculated according to the table under Point 4.2) is less

than or equal to that shown in the TECHNICAL DATA table.

- Try manually the window opening, checking for and if necessary eliminating any sticking points that could

cause a malfunction.

- Manually test the maximum opening of the window, checking that it is greater than the travel set by the

actuator.

Top-hung outward opening window: Overall dimensions and fixing holes

27 325 27

17.5

54.4

414

99

37

38.5

10

Filo Serramento

27 325 27

99.5

74 .5

55

41

55

74 .5

414

32.5

106.3

Filo Serramento

Bottom-hung inward opening window: Overall dimensions and fixing holes

27 325 27

17.5

54.4

414

99

37

38.5

10

Filo Serramento

27 325 27

99.5

74 .5

55

41

55

74 .5

414

32.5

106.3

Filo Serramento

5. INSTALLATION

8

Bottom-hung inward opening window: Top-hung outward opening window:

CAUTION If the window is of the bottom-hung type, check that the limiting arms have been fitted to

prevent the window from accidentally falling down.

Bottom-hung inward opening window: With a pencil,

mark the mid-point “X” of the window frame.

Top-hung outward opening window: With a pencil, mark

the mid-point “X” of the window frame.

Bottom-hung inward opening window: Top-hung outward opening window:

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hungoutward opening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outwardopening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

9

ENGLISH

Bottom-hung inward opening window: Top-hung outward opening window:

Pre-fit the support brackets to the frame using the alignment template.

Drill holes in the frame using the template supplied or the measurements shown on Page 7.

Fix the brackets and the fixings, using suitable screws.

Bottom-hung inward opening window: Top-hung outward opening window:

Stick the alignment template lable on the frame.

Drill holes in the frame using the template supplied or the measurements shown on Page 7.

Fix the brackets and the fixings, using suitable screws.

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outwardopening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outward opening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outward opening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outwardopening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outward opening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

= =

Min 420mm

= =

Min 420 mm

= =

Min 420mm

= =

Min 420 mm

telaio / frame / cadre / rahmen / armazón

finestra / window / fenêtre / fenster / ventana

finestra / window / fenêtre / fenster / ventana

telaio / frame / cadre / rahmen / armazón

Finestra a sporgere

Top-hung outward opening

Fenêtre à l’italienne

Klappfenster

Ventana projectante

Finestra a vasistas

Bottom-hung inward opening

Fenêtre à soufflet

Kippfenster

Ventana abatible

10

Bottom-hung inward opening window: Top-hung outward opening window:

Insert the side fulcrum pin into the support bracket

Move the actuator towards the window frame in order to insert the (opposite) side fulcrum pin into the

support bracket

Rotate the actuator, as shown in the following drawing, to fix it firmly.

11

ENGLISH

Bottom-hung inward opening window: Top-hung outward opening window:

Rotate the actuator so as to allow the window to shut.

Rotate the actuator in the opposite direction so that the end of the

chain can be inserted correctly inside the bottom-hung window fixing.

Rotate the actuator in the opposite direction so that the end of the

chain can be inserted correctly inside the top-hung window fixing.

Join the chain to the fixing by inserting the relevant

locking pin.

Join the chain to the fixing by inserting the relevant

locking pin. Clip the cover in place.

12

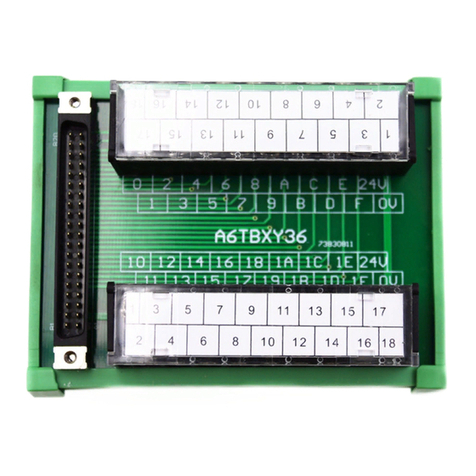

Bottom-hung inward opening window: Top-hung outward opening window:

Removal of end cap and rubber cover.

Positioning the DIP-switch

13

ENGLISH

Select the stroke distance required by following the setting of the DIP-switches according to the scheme

below. Note: each DIP-switch has three possible positions.

Liwin 350N

Stroke Dip-switch 1 Dip-switch 2

420

Top Top

Middle Middle

Botton Botton

400

Top Top

Middle Middle

Botton Botton

350

Top Top

Middle Middle

Botton Botton

300

Top Top

Middle Middle

Botton Botton

250

Top Top

Middle Middle

Botton Botton

200

Top Top

Middle Middle

Botton Botton

150

Top Top

Middle Middle

Botton Botton

Stroke Dip-switch 1 Dip-switch 2

100

Top Top

Middle Middle

Botton Botton

50

Top Top

Middle Middle

Botton Botton

Liwin 250N

Stroke Dip-switch 1 Dip-switch 2

200

Top

Unavailable

Middle

Botton

250

Top

Unavailable

Middle

Botton

380

Top

Unavailable

Middle

Botton

14

5.2 Electrical connection

Wire in the apparatus according to the electrical supply required by the actuator (see label on product),

following the table below.

230 Vac supply 24 Vdc supply

1

Blue

Neutral / Common

1

Blue

Positivo

2

Black

Phase / Open

2

Brown

Negativo

3

Brown

Phase /Closed

4

White Data (2/3/4 W-Net actuators)

4

White

Data (2/3/4 W-Net actuators)

5

Yellow Data (2/3/4 W-Net actuators)

5

Yellow

Data (2/3/4 W-Net actuators)

6

Green Data (2/3/4 W-Net actuators)

6

Green

Data (2/3/4 W-Net actuators)

Electric 230 Vac wiring Radio version wiring Electric 24 Vdc wiring

110/230V~ 50/60Hz F

N

123

24 Vdc -

+

12

Electric 230 Vac wiring

(2/3/4 W-Net actuators)

Radio version wiring

(versioni 2/3/4 W-Net)

Electric 24 Vdc wiring

(2/3/4 W-Net actuators)

110/230V~ 50/60Hz F

N24 Vdc -

+

123

4

5

6

4

5

6

4

5

6

4

5

6

4

5

6

4

5

6

12

110/230V~ 50/60Hz F

N24 Vdc -

+

123

4

5

6

4

5

6

4

5

6

4

5

6

4

5

6

4

5

6

12

230V~ 50Hz

13

F

N

4

5

6

4

5

6

4

5

6

230V~ 50Hz

13

F

N

110/230V~ 50/60Hz F

N

123

24 Vdc -

+

12

230V~ 50Hz

13

F

N

4

5

6

4

5

6

4

5

6

230V~ 50Hz

13

F

N

230V~50HZ

230V~50HZ

15

ENGLISH

5.3 Operating test

Press the control button and close the window, checking that:

A. The window is completely closed. If it is not, check that the gap between the window and the frame is bigger

than or equal to 0 mm. If necessary, insert spacers so as to obtain the correct gap.

B. The chain is perfectly vertical to the window frame. If necessary adjust the fixing bracket by using the

screws and slots.

Having reached the correct closing position, press the control button and open the window in order to check

that the actuator runs freely over the full travel set up.

Having achieved the required opening run, press the control button again to close the window. Once the window

has completely closed, check that the screws, supports and fixings are tightened correctly, and that the seals

are sufficiently compressed.

Installation completed

Bottom-hung inward opening window: Top-hung outward opening window:

Insert the rubber DIP-switch cover and close the end cap

CAREFUL!! - after installation the 4 covers must be perfectly closed.

16

6. MAINTENANCE, EMERGENCY ACTION &

CLEANING

If it becomes necessary to manually disconnect the window from the actuator due to: a power failure,

mechanical breakdown, maintenance, or cleaning the exterior of the window, follow the step sequence

described on Page 11 in reverse order.

BEWARE OF THE DANGER of the window falling; as the window is free to fall, as it is no longer held up by the chain.

Once the maintenance or cleaning operations have been completed, repeat the sequence described on Page 11.

ATTENTION!

Before operating the actuator, please make sure that the product has been fixed at the right position

OK

no 2mm

17

ENGLISH

8. FAQ (frequently asked questions)

7. PROTECTION OF THE ENVIRONMENT

Some parts inside the actuator are not recyclable (plastic materials and electronic parts) and cannot be

considered normal refuse. They must be disposed of correctly. In case of doubt, consult the relevant refuse

disposal body.

Question Cause Remedy

The actuator is not

operating

No voltage supply

Check the electrical cut-out or safety

switch is “On”.

A cable may not be connected. With volta-

ge supplied | Check the actuator voltage

corresponds to voltage supply detected.

With voltage supplied Check the actuator voltage corresponds

to voltage supply detected

The actuator is not travel-

ling the distance required

The window opening is not

as required

Check that according to the table on

Page 13 the DIP-switches are set for the

correct travel.

The chain is bent and not

perfectly linear

Detach the chain from the fixing and

check that the limiting arm allows the

actuator to travel the complete run. If

this does not happen, adjust the limiting

arm so that the actuator travels the

whole distance..

The actuator pulls out the

screws

Fixings (bottom-hung

window and/or top-hung

window) are no longer faste-

ned to the frame

Check that suitable fixings have been

used.

Check that, on closing, the chain is

perfectly perpendicular to the frame. If

not, check that the fitting was carried out

according to the Installation Sequence,

5.1.

18

Fratelli Comunello SpA provides a warranty for thirty-six months for the correct functioning of the actuators

from the date of manufacture, provided that the performance specifications indicated in the product

instruction manuals are respected. Free of charge repair and replacement of components that are found to

be faulty according to the indisputable judgment of the company’s technical staff shall be guaranteed at the

sole discretion of Fratelli Comunello Spa, and so excluding any claim for damages made by others. Warranty

material shall be returned to Fratelli Comunello S.p.a. headquarters carriage paid and will then be shipped

to the customer carriage unpaid. The material found to be faulty and returned to Fratelli Comunello S.p.a.

shall remain property of the Seller.

Any cost resulting from any work needed to repair the defect or to replace the material shall be charged to

the Buyer. No compensation shall be allowed for the period of device inactivity. Work under warranty does not

prolong the warranty period.

The defect of the product shall be reported by the Buyer within 8 (eight) days from its discovery or from the

date of delivery of the goods, under penalty of invalidation of the warranty. Such claim shall be notified in

writing.

Warranty does not cover:

Any product defect or damage that may have been incurred during transport; any defect or damage arising

from any fault and/or from neglect, inadequacy and misuse of the electrical wiring in the Buyer’s property;

any defect or damage caused by any repairs carried out by non authorised personnel or by incorrect use/

installation (with reference to this, system maintenance is recommended every 6 months) or if not original

spare parts are used; any defect caused by chemicals or atmospheric conditions. The warranty does not cover

any cost neither for consumable materials nor for alleged defects or convenient surveys.

Product Features

Fratelli Comunello SpA products are subjected to continue changes and improvements; their technical

features and image may therefore change without previous notice.

Competent court

Since the contract of sale is confirmed by an Order Confirmation drawn up in Rosà, any such dispute shall be

settled by the laws of Italy and by the court of Bassano del Grappa (VI).

9. GUARANTEE

ENGLISH

This manual suits for next models

1

Table of contents