TECH ST-81 User manual

1

Declaration of Conformity no. 23/2007

TECH, a company with a seated in Andrychów (43-120) at l.

St. Batorego 14, declares with f ll responsibility that the

thermal controller ST-28 (230V, 50Hz) prod ced by the

company complies with the provisions of the Ordinance of the

Minister of Economy, Labo r and Social Policy (Dz U.03.49.414)

of 12 March 2003 introd cing the provisions of the Low Voltage

Directive (LVD) 2006/95/ECE and the Ordinance of the Minister

of Infrastr ct re (Dz.U.03.90.848) of 02 April 2003 introd cing

the provisions of the Directive EMC 89/336/EEC.

ST 81 controller Has passed the EMC tests with the maxim m

loads applied.

The compatibility eval ation has bee based on the harmonized

standards

PN-EN 60730-2-1:2002.

The prod ct Has been labelled with CE mark first on:

4 J ly 2007

Co-owners:

Paweł J ra, Jan sz Master

Andrychów, 4 July 2007

2

WA NING!

Electric device!

Before you take any steps aiming at

powering the device (connecting wires,

installation of the device etc.), make sure

the controller is not connected to the mains.

The installation should be conducted by a

certified electrician.

Prior to commissioning of the controller, the

measurements of the grounding efficiency

of the electric motors and a boiler as well as

insulation measurements must be taken.

3

I. Description

In order to check the fl e gas o tlet temperat re, press EXIT

(hold for several seconds) ntil the following screen is

displayed:

The left of the screen shows the boiler temperat re; the middle

of the screen shows the fl e gas o tlet temperat re; the right

of the screen shows the power of the fan. Press EXIT to ret rn

to the main men .

ST-81thermal controller is designed for central heating boilers.

ST -81 thermoreg lator is designed for wood-fired central

heating boilers.

It controls water circ lating p mp and air injection (fan).

4

C.H. Screen

H.C.W. Screen

H.C.W. Screen

Flue Gas Screen

H.C.W. Screen

Flue Gas Screen

23 Oc 26 Oc 1%

C.H. Flue Fan

However, this

type of controller cannot control rotation of the fan.

If the boiler temperat re is lower than the set temperat re, the

controller operates the blower contin o sly. If the boiler

temperat re eq als or exceeds the set temperat re, the

controller operates in the temperat re maintenance mode.

ST-81 controller ses one instr ctions for different programme

versions depending on the type of the boiler. Programme

versions are developed for each boiler man fact rer

individ ally. Any comments regarding the programme sho ld

be forwarded to a boiler man fact rer. A controller sho ld be

set p to meet individ al req irements, depending on the type

of f el and a boiler. TECH shall bear no responsibility for the

erroneo s set p of the controller.

II. Controller functionalities

This section describes controller f nctions, settings and

navigation iss es.

II.a) Main screen

D ring normal operation of the controller, the LCD display

presents the main screen with the following information:

• Boiler temperat re

• Set temperat re

This screen enables q ick adj stment of the set temperat re by

means of and . The OPTIONS b tton takes yo to the level 1

s bmen . The LCD displays two first lines of the men . Yo can

navigate aro nd the men s by means of and .

The OPTIONS b tton takes yo to another s bmen or enables

an option (applies the changes).

The EXIT b tton takes yo to the parent men .

5

II.b) Firing-up

The Firing- p f nctions switches the fan on or off d ring the

contin o s operation of the controller. If the boiler temperat re

exceeds 30 °C b t does not reach the set val e, the b tton is

sed as a START/STOP b tton and the LCD displays Fan On/Off

message. This f nction allows to enable or disable fan d ring

the boiler operation.

The stat s is indicated by an asterisk in the right bottom corner

of the display (asterisk indicates that the fan is enabled). The

f nction allows safe operation of the boiler. The f rnace door

m st not be opened when the fan is on.

II.c) Manual operation

The controller can operate in man al mode for the convenience

of the ser.

This f nction allows independent switching of all elements.

The OPTIONS b tton enables the blower. The blower is on ntil

the OPTIONS b tton is pressed again.

The OPTIONS b tton enables/disables the central heating water

p mp.

6

The OPTIONS b tton enables/disables the hot water p mp (of

the boiler).

The OPTIONS b tton enables/disables the alarm.

II.d) The temperature of activation CH and UH pumps.

The option enables set p of CH p mp and UHW p mp

activation temperat res (this refers to temperat res meas red

on the boiler). Both p mps do not work below the set

temperat re. If the set temperat re is exceeded, both p mps

are activated b t they operate depending on the settings i.e.

they are activated interchangeably (see p mp priority f nction

or contin o s CH p mp).

7

II.e) Hysteresis of the boiler

This option allows set p of the set temperat re hysteresis. This

val e represents a difference between the temperat re of the

temperat re maintenance mode activation and the operation

mode restoration temperat re (e.g. if the set temperat re is

60°C and the hysteresis val e is 2°C, the temperat re

maintenance mode will be activated at 60°C, whereas the

operation mode will be restored pon drop to 58°C. The

hysteresis val e may range from 2°C to 6°C.

II.f) Hysteresis of UH

This option allows set p of the set temperat re hysteresis. This

val e represents a difference between the set temperat re

(req ired boiler temperat re) and the boiler temperat re (e.g.

if the set temperat re is 55°C and the hysteresis val e is 5°C,

pon reaching the set temperat re i.e. 55°C, UHW p mp is

t rned off and CH p mp is activated. The UHW p mp will be

activated pon temperat re drop to 50°C).

8

II.g) UH pump

Activation of UHW p mp (by selecting TURN ON) makes the

controller switch to boiler priority mode. In this mode, the

boiler p mp ( UHW) is activated ntil the set temperat re is

reached. Then, the p mp is t rned off and the CH circ lating

p mp is activated.

The temperat re of the UHW p mp is adj sted by pressing (for

a few seconds) the EXIT b tton. The LCD will display the set

temperat re and the boiler temperat re. To activate the UHW

p mp, the set temperat re m st be above the p mp activation

threshold (see page 6 II d). The range of the set temperat re is

adj sted by means of and . After a few seconds, the display is

restored. Upon reaching the set temperat re, the UHW p mp

is deactivated and the CH p mp starts.

In this mode, the operation of the fan is limited to 62°C at the

boiler to prevent boiler overheating. This condition contin o s

ntil the boiler set temperat re is reached. Upon reaching the

temperat re, the UHW p mp is deactivated and the CH p mp

starts. The CH p mp contin o s to operate ntil the boiler

temperat re drops below the set val e. Then, the CH p mp is

t rned off and the UHW p mp is started. UHW priority means

that the tility hot water is heated first and the water in

radiators is heated afterwards.

WARNING: The boiler sho ld be fitted with non-ret rn valves in

the CH and UHW circ lation systems. The valve on the UHW

p mp prevents discharge of hot water from the boiler. The

valve on CH p mp prevents hot water from entering the ho se.

9

II.i) Summer mode

Upon activation of this f nction, this p mp is deactivated and

the UHW p mp starts above the set temperat re (see the

p mp activation temperat re f nction), whereas the UHW

p mp operates contin o sly. The s mmer f nction allows to

adj st only the boiler set temperat re for heating the water in

the vessel. Upon activation of this f nction, the LCD displays

three items: Boiler temperat re (CH), vessel temperat re

( UHW) and set temperat re.

II. j) Fixed CH Pump

In this mode, p mps are activated conc rrently above the set

temperat re. (see p mp activation temperat re f nction) CH

p mp operates contin o sly, whereas the UHW p mp is

deactivated pon reaching temperat re set on the boiler.

Warning: For operation in this mode, there sho ld be a three-

way valve or other mixing valve installed to ens re different

environment and boiler temperat res.

10

II. k) Default settings

The controller comes with a defa lt set p for operation.

However, it sho ld be c stomized to meet the individ al needs.

Defa lt settings may be restored at any time. By selecting the

defa lt settings, all c stomized settings of boiler are deleted.

This allows for setting new parameters of the boiler.

III. Safety measures

To ens re maxim m safety and fail re-free operation, the

controller has been eq ipped with a range of safety meas res.

The alarm stat s is indicated by a so nd and a special message

is displayed on the LCD.

To restore operation of the boiler, press the OPTIONS b tton.

III.a) Thermal protection

This is an a xiliary bimetal mini-sensor (next to the f rnace

sensor) which c ts off the fan o tp t pon exceeding the limit

val e of 85°C. This prevents boiling of the water in the system

in the case of boiler overheating or controller fail re. This type

of safety temperat re limiter restores the starting position:

a tomatic

III.b) Automatic sensor control

In the case of fail re of the CH temperat re sensor, an alarm is

activated and the LCD displays a message:

11

The blower is activated. The p mp starts irrespective of the

c rrent temperat re. The controller awaits for pressing the

OPTIONS b tton. Next, the alarm is deactivated and the normal

operation of the controller is restored.

III.c) Temperature protection

The controller has an a xiliary protection in case of damage to

a bimetal sensor: pon exceeding the temperat re of 85°C, the

alarm is activated and the LCD displays:

III. d) Boiling protection

This f nction prevents excessive temperat re of the boiler (only

when the boiler priority f nction is on) i.e. when the boiler set

temperat re is e.g. 55°C and the c rrent boiler temperat re is

62°C, the controller activates the fan. When the temperat re

reaches as m ch as 80°C, the CH p mp is activated. If the

temperat re contin o s increasing, the alarm t rns on at 85°C.

This may happen, when the boiler is damaged, the sensor is

installed improperly and the p mp is damaged. However, if the

temperat re decreases, at the threshold val e of 60 °C, the

blower will be started and it will contin e operation ntil the

boiler set temperat re is reached.

III.e) Fuse

The controller is eq ipped with a WT 2.5A f se to protect the

means.

WA NING: No fuse of the higher value should be used.

Installation of the fuse of a higher ampere value may

result in a damage to the controller.

12

IV. Maintenance

The technical conditions of the wires of the ST-28 controller

sho ld be inspected prior to the heating season as well as

d ring its d ration. The mo nting of the controller sho ld be

checked and the d st and other contamination sho ld be

removed. F rthermore, the meas rements of the gro nding

efficiency of the electric motors (of CH p mp, UHW p mp and

fan) m st be taken.

No. Item Unit

1Power s pply V 230V/50Hz +/-10%

2Power inp t W 2

3Environment temperat re OC10÷50

4Circ lation p mp o tp t load A 1

5Fan o tp t load A 1

6Temperat re meas rement range OC0÷85

7Meas rement acc racy OC 1

8Temperat re setting range OC30÷80

9Temp. Sensor d rability OC- 25 ÷100

10 F se A,2 5

13

V. Technical support

Any defects sho ld be forwarded to the following address:

TECH Sp.j.

34-120 Andrychów ul. St. Batorego 14

tel. 33 8705105 , 33 8759380

VI. Instllation

WARNING: The installation sho ld be cond cted by a certified

electrician! The device cannot be powered d ring theinstallation

(make s re the pl g is not connected to the means).

WARNING: Incorrect installation of the wires may res lt in a

damage to the controller. The controller cannot operate in a

closed central heating circ lation system. The system m st

incorporate safety valves, press re valves, and a s rge tank to

prevent boiling of water in the central heating system.

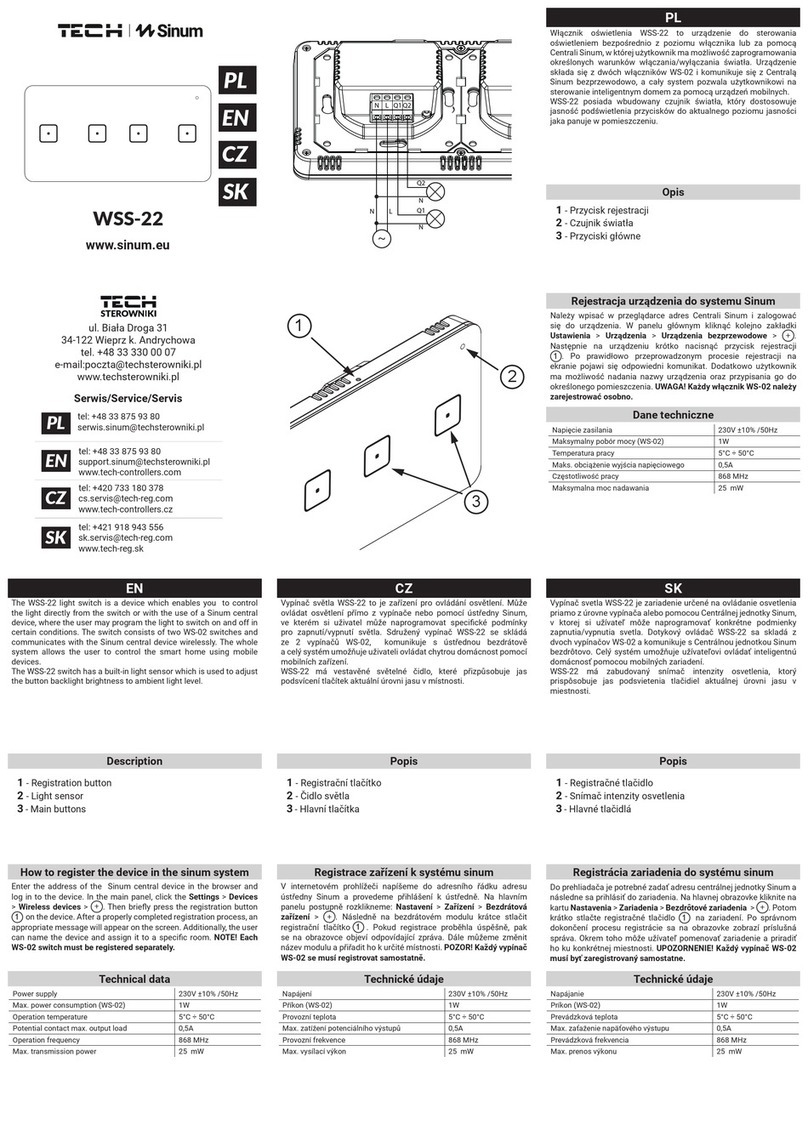

VI.a) Controller wiring diagram

Please, pay special attention d ring installation of the controller

wiring.

Make s re that the gro nd cond ctor is connected properly.

14

Contents

I. Description...........................................................................................................................4

II. Controller f nctionalities...............................................................................................5

II. a) Main screen.............................................................................................................5

II. b) Firing- p...................................................................................................................5

II. c) Man al operation..................................................................................................6

II. d) The temperat re of activation of CH and UHW p mps ......................6

II. e) Hysteresis of the boiler....................................................................................7

II. f) Hysteresis of UHW...............................................................................................8

II. ) UHV p mp ..............................................................................................................8

II. i) S mmer mode......................................................................................................10

II. j) Fixed CH P mp ....................................................................................................11

II. k) .Defa lt settings..................................................................................................11

III. Safety meas res..........................................................................................................12

III. a) Thermal protection..............................................................................................12

III. b) A omatic sensor control...................................................................................12

III. c) Temperat re protection....................................................................................13

III. d) Boiling protection................................................................................................13

III. e) F se...........................................................................................................................13

IV. Maintenance...................................................................................................................14

V. Technical s pport..........................................................................................................15

VI. Installation......................................................................................................................16

15

16

Other manuals for ST-81

1

This manual suits for next models

1

Table of contents

Other TECH Controllers manuals