Mowox PBC 33 BH User manual

1

ORIGINAL INSTRUCTIONS

INFORMATION/MANUALS/SERVICE

Model:

PBC 33 BH/PBC 32 B (DYM246601)

PBC 43 BH/PBC 42 B(DYM246801)

PT 25 LH (DYM246406)

2018

Manufacturer:

Ningbo Daye Garden Machinery Co., Ltd.

No. 58 Jinfeng Road, Yuyao, Zheijiang 315403, P.R. China

www.daye-garden.com

Importer:

Daye Europe GmbH

Parkstraße 1 a

66450 Bexbach, Germany

www.mowox.com

2

SERVICE CONTACTS

COUNTRY

TELEPHONE EMAIL

GERMANY

+49 6831 4880 9824

service-de@mowox.com

AUSTRIA

+43 720 230804

service-at@mowox.com

SWITZERLAND

+41 43 50 888 04

service-ch@mowox.com

FRANCE

+33 1 8288 4290

service-fr@mowox.com

LUXEMBURG

+352 27 863004

service-lu@mowox.com

BELGIUM

+32 2 5889602

service-be@mowox.com

NETHERLANDS

+31 20 8080 732

service-nl@mowox.com

FINLAND

+358 75 3251440

service-[email protected]

SPAIN

+34 91 123 5903

service-esp@mowox.com

PORTUGAL

+351 308810278

service-pt@mowox.com

UNITED KINGDOM

+44 2080680844

service-en@mowox.com

ITALY

+39 0694801738

service-it@mowox.com

POLAND

+48 22 3003915

service-pl@mowox.com

3

CONTENTS

SECTION 1 SYMBOLS ..........................................................................................................4

SECTION 2 SAFETY INSTRUCTIONS .......................................................................................4

SECTION 3 DESIGNATION OF PARTS…………………......................…………........................ 9

SECTION 4 TECHNICAL DATA................................................................................................ 10

SECTION 5 MOUNTING THE HANDLE ....................................................................................11

SECTION 6 MOUNTING THE PROTECTOR............................................................................ 13

SECTION 7 MOUNTING THE CUTTER BLADE / NYLON CUTTING HEAD........................... 14

SECTION 8 FUELS/REFUELING.............................................................................................. 16

SECTION 9 MOUNTING THE SHOULDER STRAP................................................................. 16

SECTION 10 IMPORTANT OPERATING POINTS/STOPPING THE CUTTER/TRIMMER.......19

SECTION 11 RESHARPENING THE CUTTING TOOL ............................................................21

SECTION 12 SERVICING INSTRUCTIONS .........................................................................23

SECTION 13 STORAGE ............................................................................................................25

SECTION 14 TROUBLESHOOTING .........................................................................................25

SECTION 15 EC DECLARATION OF CONFORMITY……………...................................……...26

4

1. SYMBOLS

Please adhere to the following safety instructions on the unit and in this instruction manual:

2. SAFETY INSTRUCTIONS

General Instructions

1. To ensure correct operation, make sure that you read and fully understand this Instruction manual to

familiarize yourself with how to use the Brush Cutter/String Trimmer. Using this equipment without

understanding how to operate it correctly may result in serious injury to yourself or others.

2. Only lend the Brush Cutter/String Trimmer to people who have proved experience with Brush Cutter/String

Trimmers. Always lend them this instruction manual at the same time.

Read instruction Manual

Take Particular care and Attention

Keep distance

Beware of thrown objects hit by cutting

attachment.

Protective gloves must be worn

Kickback

Beware of blade thrust

Wear sturdy boots with non-slip

soles. Steel toed safety boots are

recommended.

Wear protective helmet, eye

and ear protection

Do not use metal blades

(only for DYM246406)

Hot surfaces- Burns to

fingers or hands

Maximum permissible tool

speed (for DYM246601 and

DYM246801)

Beware of blade thrust This unit is not intended for

use with a toothed saw type

blade

Maximum permissible tool

speed (only for PT 25 LH

(DYM246406))

Your tool noise is not more than

XXdB.

5

3. If this is your first time using an engine powered cutter, consult your dealer for basic Instructions.

4. Children and young persons aged under 18 years must not be allowed to operate the Brush Cutter/String

trimmer. Persons over the age of 16 years may however use the device for training purposes, only whilst

under supervision of a qualified trainer.

5. Use Brush Cutter/String trimmers with the utmost care and attention.

6. Only operate the Brush Cutter/String Trimmer if you are in good physical condition. Perform all work calmly

and carefully. User must accept responsibility for those around them.

7. Never use the Brush Cutter/String trimmer after consumption of alcohol or medicines, or if feeling tired or ill.

WARNING! This power tool produces an electromagnetic field during operation. This field may under

some circumstances interfere with active or passive medical implants. To reduce the risk of serious or fatal

injury, we recommend persons with medical implants to consult their physician and the medical implant

manufacturer before operating this machine.

Intended use of the machine

The Brush Cutter/String trimmer is only intended for cutting grass, weeds, bushes, and other such

undergrowth, and should not be used for any other purpose such as edging or hedge cutting as this may

cause injury.

Personal protective equipment

1. Always wear clothing that is both functional and appropriate to your work, i.e. tight-fitting, but not so tight

as to cause uncomfortable movement. Do not wear either jewelry or clothing with could become

entangled with bushes or shrubs.

2. In order to avoid head, eye, hand or foot injuries, as well as to protect your hearing during operation, the

following protective equipment and protective clothing must be used while using the Brush Cutter/String

trimmer.

3. Always wear a helmet where there is a risk of falling objects. The protective helmet is to be checked at

regular intervals for damage and is to be replaced at the latest after 5 years. Use only approved protective

helmets.

4. The visor of the helmet (or alternatively goggles) protects the face from flying debris and stones. During

operation of the Brush Cutter/String trimmer, always wear goggles, or a visor to prevent eye injuries.

5. Wear adequate noise protection equipment to avoid hearing impairment (earmuffs, ear plugs etc.).

6. The work overalls protect against flying stones and debris. We strongly recommend that the user wears

work overalls.

7. Special gloves made of thick leather are part of the prescribed equipment and must always be worn

during operation of the Brush Cutter/String trimmer.

8. When using the Brush Cutter/String trimmer, always wear sturdy shoes with a non-slip sole. This protects

against injuries and ensures a good footing.

Emergency

Familiarise yourself with the use of this product by means of this instruction manual. Memorise the safety

directions and follow them to the letter. This will help to prevent risks and hazards.

1. Always be alert when using this product, so that you can recognize and handle risks early. Fast intervention

can prevent serious injury and damage to property.

2. Turn the product off and disconnect it from the power supply if there are malfunctions. Have the product

checked by a qualified professional and repaired, if necessary, before you operate it again.

Residual risks

6

Even when the power tool is used as prescribed it is not possible to eliminate all residual risk factors. The

following hazards may arise in connection with the power tool’s construction and design:

1. Damage to lungs if an effective dust mask is not worn.

2. Damage to hearing if effective hearing protection is not worn.

3. Damages to health resulting from vibration emission if the power tool is being used over longer period of

time or not adequately managed and properly maintained.

Starting the brush cutter

1. Please make sure that there are no children or other people within a working range of 15 meters (50ft);

also pay attention to any animals in the working vicinity.

2. Before use, always check that the Brush Cutter/String trimmer is safe for operation:

Check the security of the cutting tool that the control lever can be operated easily, and that control lever

lock is functioning correctly.

3. Rotation of the cutting tool during idling speed is not allowed. Check with your dealer if you think the

equipment may need adjusting. Checks to make sure that the handles are clean and dry, and that the

start/stop switch is functioning correctly.

4. Start the Brush Cutter/String trimmer only in accordance with the instructions. Do not use any other

methods for starting the engine!

5. Only use the Brush Cutter/String trimmer and the tools for specified purposes.

6. Only start the Brush Cutter/String trimmer engine after the equipment is fully assembled. Do not operate

the equipment until all of the appropriate accessories are attached.

7. Before starting, make sure that the cutting tool has no contact with hard objects such as branches, stones

etc. as the cutting tool will revolve when starting.

8. Switched off immediately if any type of engine problem occurs.

9. Should the cutting tool hit stones or other hard objects, immediately switch off the engine and inspect the

cutting tool.

10. Inspect the cutting tool at short regular intervals for damage (inspect for hairline cracks using the tapping

test).

11. Only operate the Brush Cutter/String trimmer after attaching and adjusting the shoulder strap to the

correct length. The shoulder strap must be adjusted to the user’s size and fastened to prevent fatigue

during operation of the equipment. Never hold the cutter with one hand during operation.

12. During operation, always hold the Brush Cutter/String trimmer with both hands. Always ensure you are on

safe footing.

13. Operate the Brush Cutter/String trimmer in such a manner as to avoid inhalation of the exhaust gases.

Never run the engine in enclosed space such as inside a room (risk of gas poisoning). Carbon monoxide

is an odorless gas.

14. Always switch off the engine when resting, or if you intend to leave the Brush Cutter/String Trimmer

unattended, and place it in a safe location to prevent injury to other People and damage to the equipment.

15. Never put the hot Brush Cutter/String trimmer onto dry grass or onto any combustible materials.

16. The cutting tool must always be equipped with appropriate guard. Never run the cutter without this guard!

17. All protective installations and guards supplied with the machine must be used during operation.

18. Never operate the engine with faulty exhaust muffler.

19. Shut off the engine during transport.

20. When transporting the equipment, always attach the cover to the cutting blade.

21. Ensure the Brush Cutter/String trimmer is positioned safely during transport to avoid fuel leakage.

22. When transporting the Brush Cutter/String trimmer, ensure that the fuel tank is completely empty.

7

23. When unloading the Brush Cutter/String trimmer from the truck or other such vehicle, never drop the

engine to the ground, as doing so may severely damage the fuel tank.

24. Unless in an emergency, never drop or cast the Brush Cutter/String trimmer to the ground as doing so

may severely damage the Brush Cutter/String trimmer.

25. Always lift the entire equipment from the ground when moving it. Dragging the Equipment on its fuel tank

is extremely dangerous and may cause fuel to leak, which May cause fire.

26. If the equipment gets heavy impact or fall, check the condition before continuing work. Check the fuel

system for fuel leakage and the controls and safety devices for malfunction. If there is any damage or

doubt, ask our authorized service center for the inspection and repair.

Refueling

1. Shut off the engine during refueling, keep away from open flames and do not Smoke during refueling.

2. Ensure mineral oil products do not come into contact with skin. Do not inhale fuel vapor. Always wear

protective gloves during refueling.

3. Change and clean protective clothing at regular intervals.

4. Take care not to spill either fuel or oil in order to prevent soil contamination(environmental protection).

Clean the Brush Cutter/String trimmer immediately after fuel has been spilt.

5. To prevent soil contamination (environmental protection), make sure you do not spill fuel or oil on the

ground. If you do spill fuel, clean the Brush Cutter/String Trimmer immediately.

6. Make sure fuel does not come into contact with your clothing. If fuel does come into contact with your

clothing, change your clothing immediately to prevent fire.

7. Inspect the fuel cap at regular intervals making sure that it can be securely fastened and does not leak.

8. Carefully tighten the fuel tank cap. Once refueling is complete, move to a location at least 3 meters away

from where you refueled before starting the engine.

9. Never refuel in enclosed space such as inside a room. Doing so may cause an Explosion due to the

accumulation of fuel vapor at ground level.

10. Only transport and store fuel in approved containers. Make sure the fuel stored is not accessible to

children.

Method of operation

1. Only use the Brush cutter/String trimmer in good light and visibility. During the winter season, beware of

slippery or wet areas such as icy or snow-covered areas (risk of slipping).Always ensures you are on

safe footing.

2. Never cut above waist height.

3. Never stand on a ladder while using the Brush cutter/String trimmer.

4. Never climb up into trees to use with the Brush cutter/ String trimmer.

5. Never work on unstable surfaces.

6. Remove sand, stones, nails etc. found within the working range. Foreign objects may damage the

cutting tool and can cause dangerous kick-backs.

7. Before starting to cut, make sure the cutting tool has reached full working speed.

8. If grass or branches get caught between the cutting tool and guard, always stop the engine before

cleaning. Otherwise unintentional blade rotation may cause serious injury.

9. Take a rest to prevent loss of control caused by fatigue. We recommend taking a 10 to 20-minute rest

every hour.

Kickback (blade thrust)

1. When operating the brush cutter, uncontrolled kickback may occur.

2. Kickbacks occur frequently when attempting to cut with the 12 to 2 o’clock section of the blade.

3. Never apply the 12 and 2 o’clock section of the brush cutter blade.

8

4. Never apply this segment of the brush cutter blade to solids objects, such as bushes or trees etc. that

have a diameter in excess than 3 cm. Doing so will cause the brush or the brush cutter to deflect with a

large amount of force, which is extremely dangerous and may cause injury.

Kickback prevention

To avoid kickbacks, remember the following:

5. Using the 12 and 2 o’clock section of the blade is extremely hazardous, especially when using metal

cutting tools.

6. Cutting operations using the 11 and 12 o’clock section and 2 to 5 o’clock of the blade must only be

performed by trained and experienced operators, and then only at their own risk.

The optimum cutting section for easy cutting with almost no kickback is between the 8 to 11 o’clock

section of the blade.

Cutting Tools

1. Use an applicable cutting tool for the job in hand. PBC 33 BH/PBC 32 B (DYM246601) with cutter

blade (3 teeth) and Nylon cutting head. Nylon cutting heads (string trimmer heads) are suitable for

trimming lawn grass. Metal blades are suitable for cutting weeds, high grasses, bushes, shrubs, under

wood, thicket, and the like.

2. Never use other blades including metal multi-piece pivoting chains and flail blades. Otherwise serious

injury may result.

3. When using metal blades, avoid “kickback” and always prepare for an accidental kickback. See the

section “Kickback” and “Kickback prevention”.

4. Perform this cutting work by swinging the brush cutter evenly in half-circles from right to left (similar to

using a scythe).

Maintenance instructions

1. Have your equipment serviced by our authorized service center, always using only genuine replacement

parts. Incorrect repair and poor maintenance can shorten the life of the equipment and increase the risk of

accidents.

2. Always check the condition of the cutter, in particular the cutter protective devices and shoulder strap,

before commencing work.

3. Particular attention should also be paid to the cutting blades, which must be correctly sharpened.

4. Turn off the engine and remove spark plug connector when replacing or sharpening cutting tools, and also

when cleaning the cutter or cutting tool.

Never straighten or weld damaged cutting tools.

1. Operate the Brush cutter/String trimmer with as little noise and contamination as possible. In particular,

check the correct setting of the carburetor.

2. Clean the Brush cutter/String trimmer at regular intervals and check that all screws and nuts are well

tightened.

3. Never service or store the Brush cutter/String trimmer in the vicinity of naked flames.

4. Always store the Brush cutter/String trimmer in locked rooms and with an emptied fuel tank.

5. When cleaning, servicing and storing the equipment, always attach the cover to the cutting blade.

6. Observe the relevant accident prevention instructions issued by the relevant trade associations and by the

insurance companies.

7. Do not perform any modifications on the Brush cutter/String trimmer as this will endanger your safety.

8. The performance of maintenance or repair work by the user is limited to those activities as described in

the instruction manual. All other work is to be done by an Authorized Service Agent. Use only genuine

spare parts and accessories.

9. Use of non-approved accessories and tools means increased risk of accidents.

9

First Aid

In case of accident, make sure that a first-aid box is available in the vicinity of the cutting operations.

Immediately replace any item taken from the first aid box.

When asking for help, please give the following information:

1. Place of accident

2. What happened

3. Number of injured persons

4. Kind of injuries

5. Your name

Vibration

1. People with poor circulation who are exposed to excessive vibration may experience injury to blood

vessels or the nervous system. Vibration may cause the following symptoms to occur in the fingers, hands or

wrists: “Falling asleep” (numbness), tingling, pain, stabbing sensation, alteration of skin color or of the skin. If

any of these symptoms occur, see a physician!

2. To reduce the risk of “white finger disease”, keep your hands warm during operation and well maintain the

equipment and accessories.

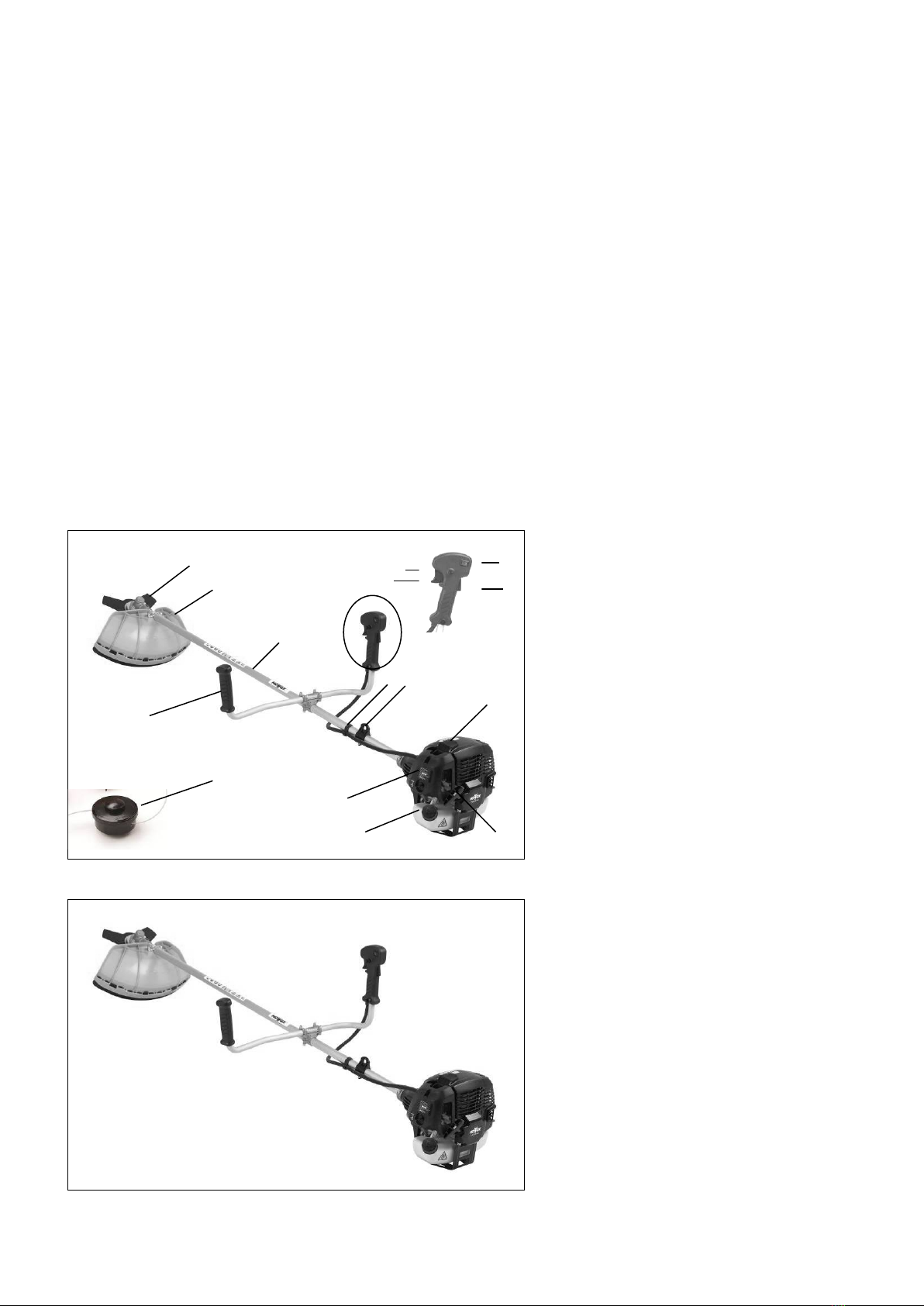

3.DESIGNATION OF PARTS

Fig.1A PBC 33 BH/PBC 32 B (DYM246601)

1

2

3

4

5 6

7

12

14

8 10

13

9

11

15

10

Fig.1B PBC 43 BH/PBC 42 B (DYM246801)

Fig.1C PT 25 LH (DYM246406)

1. Cutter blade 2. Protector(cutting tool guard) 3. Shaft 4. Lock button

5. Throttle lever 6. Switch 7. Safety lock-off lever 8. Cable hook

9.Hanger 10. Spark plug 11. Starter handle 12. Fuel tank

13. Air cleaner cover 14. Handle 15. Nylon cutting head 16.Assistant handle

17.Switch 18. Safety lock-off lever 19. Throttle lever

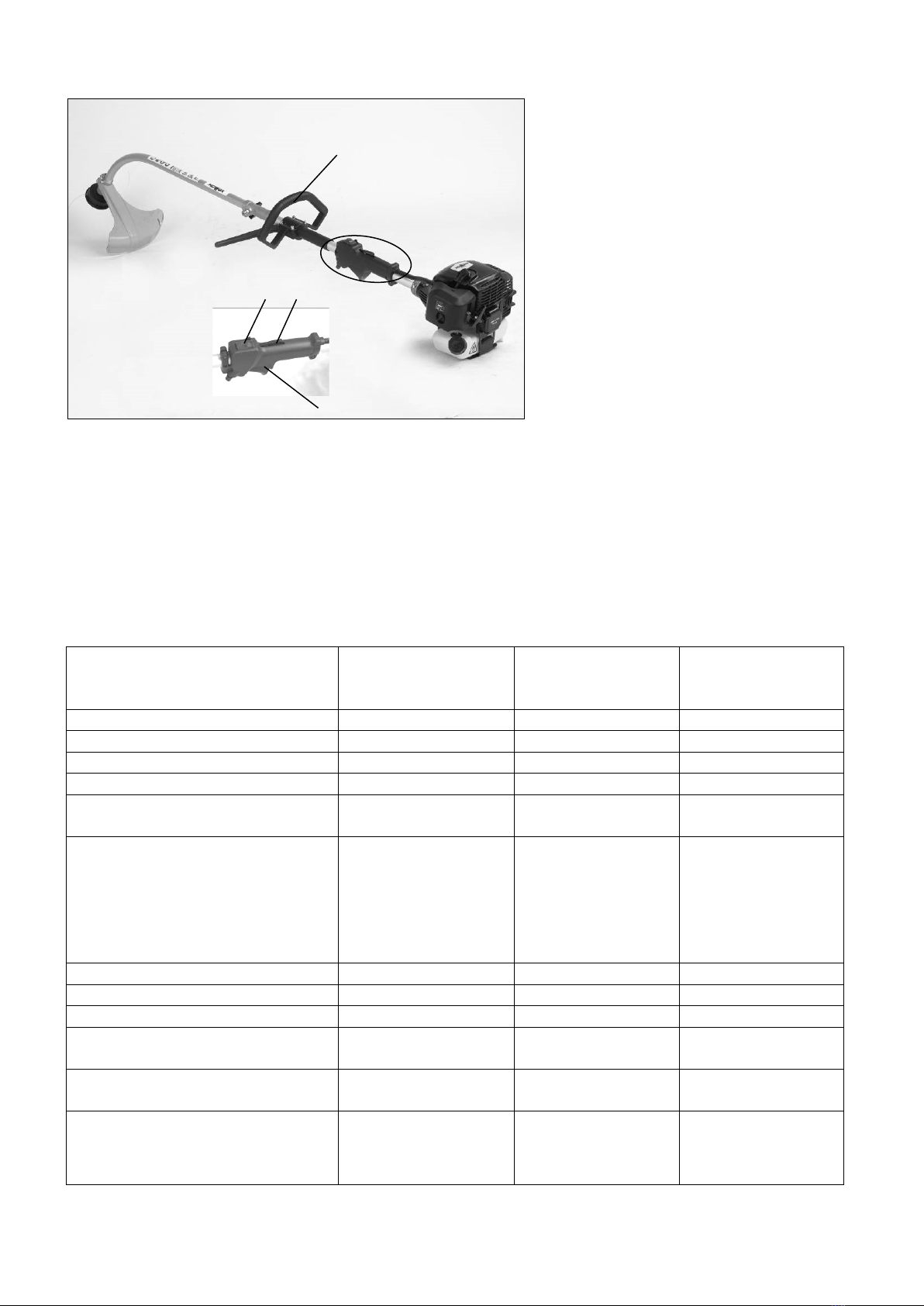

4. TECHNICAL DATA

Model PT 25 LH

(DYM246406)

PBC 33 BH/PBC

32 B

(DYM246601)

PBC 43 BH/PBC

42 B

(DYM246801)

Engine model

DYM1E34F-3E

DYM1E36F-2E

DYM1E40F-2E

Engine displacement

25.4cm

3

32.6 cm

3

42.7cm

3

Maximum engine performance

0.75kW

0.85kW

1.1kW

Rated speed of engine

7500/min.

7500/min

7500/min

Max. Rotational Frequency of the

Spindle

10000/min 10000/min 10000/min

Cutting Width: Grass trimmer:

400mm

Grass trimmer:

420mm

Brush cutter:

255mm

Grass trimmer:

420mm

Brush cutter:

255mm

Idling speed

3000/min

±

200/min

3000/min

±

200/min

3000/min

±

200/min

Clutch engagement speed

4200/min

±

200/min

4200/min

±

200/min

4200/min

±

200/min

Volume (fuel and oil tank)

0.6L

1.0L

1.0L

Vibration(Grass trimmer) :

8.838m/s2

K=1.5m/s

2

7.091m/s2

K=1.5m/s

2

6.015m/s2

K=1.5m/s

2

Vibration(Brush cutter) : /

5.811m/s2

K=1.5m/s

2

7.207m/s2

K=1.5m/s

2

Sound pressure level at the

operator’s position

(Grass trimmer):

98.1dB(A)

K=2.5dB(A) 91.7dB(A)

K=2.5dB(A) 98.8dB(A)

K=2.5dB(A)

18

16

17

19

11

Sound pressure level at the

operator’s position

(Brush cutter):

/ 91.4dB(A)

K=2.5dB(A) 98.7dB(A)

K=2.5dB(A)

Measured sound power level

(Grass trimmer) :

110.2(A)

K=1.11dB(A) 110.1(A)

K=1.52dB(A) 112.1(A)

K=2.10dB(A)

Measured sound power level

(Brush cutter) : / 109.4(A)

K=1.43dB(A) 108.5(A)

K=2.98dB(A)

Guaranteed sound power level 111dB(A) 112dB(A) 114dB(A)

Net Weight:

5.4 kg 7.5 kg 8.4 kg

5. MOUNTING THE HANDLE

CAUTION: Before doing any work on the brush cutter, always stop the engine and disconnect the spark

plug connector from the spark plug. Always wear protective gloves!

CAUTION: Ensure you have reassembled the brush cutter completely before starting it.

5.1 Mounting the U handle for PBC 33 BH/PBC 32 B (DYM246601) and PBC 43 BH/PBC

42 B (DYM246801)

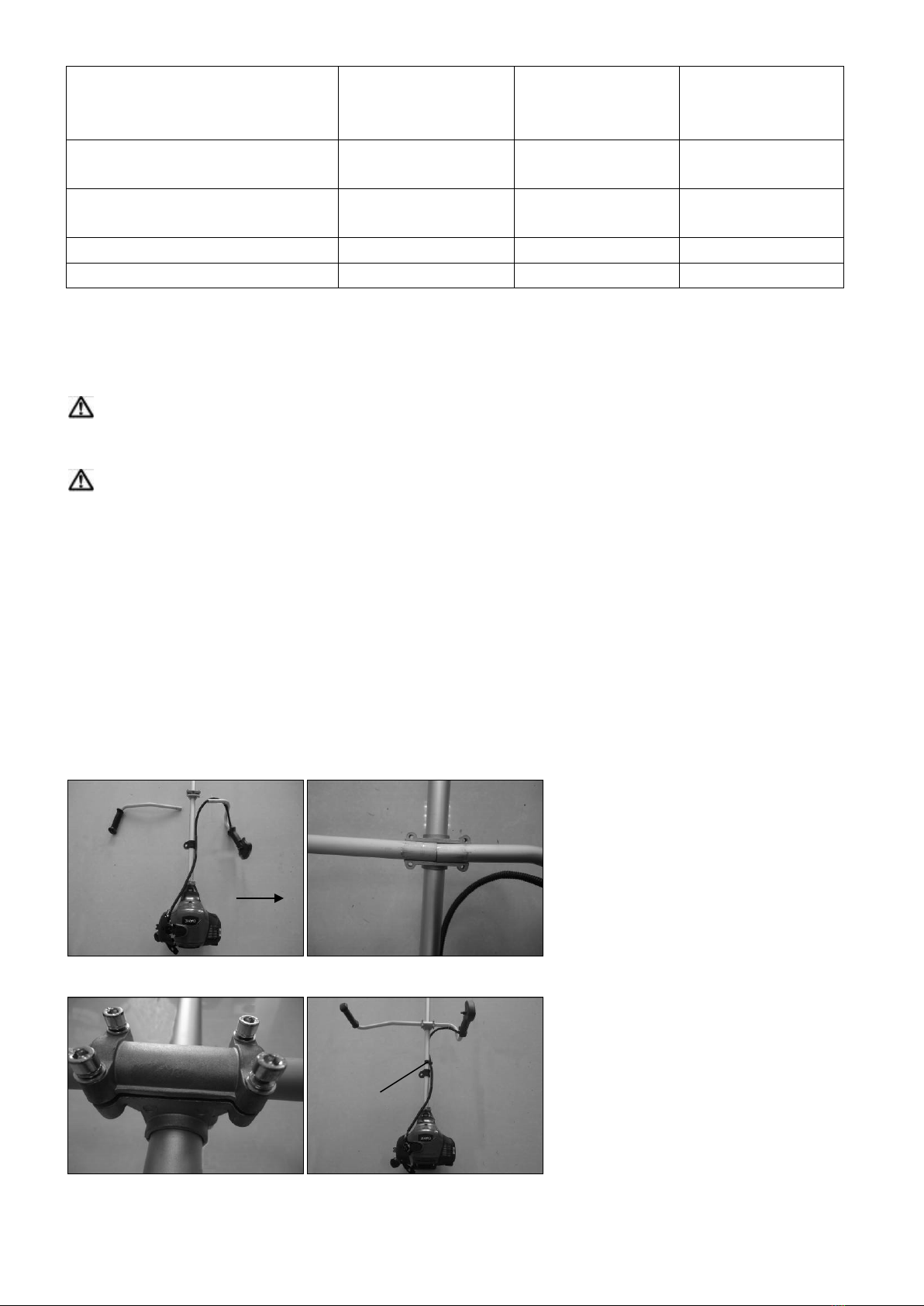

1. Place the handle: The handle with the control lever is positioned on the right (the right-hand grip side)

when viewed from the engine side, and the other handle on the left side.(Fig.2A/Fig.2B)

2. Fit the groove of the handle: Fix the attached metal with washers, bolts using the hexagon socket bolt

provided. Adjust the handle to an easy-to-operate position, and securely tighten the four hexagon socket

bolts uniformly on the right and left by wrench. (Fig.2C)

3. Place the throttle cable to the control lever side of the shaft. Attach the cable-clamp to the position shown

and then attach the cable.(Fig.2D)

4. Operate the control lever and make sure it moves smoothly.

Fig.2A Fig.2B

Right

Cable clamp

12

Fig.2C Fig.2D

5.2 Mounting the loop handle for PT 25 LH (DYM246406)

1. There are there location holes in the shaft, chose any one as an easy-to-operate position. (Fig.3A)

2. Put the assistant handle into place, make sure the limit block full seated in the limit slot. (Fig.3B/Fig.3C)

3. Fix the assistant handle with bolts, washers and nuts, tighten the four bolts. (Fig.3D/Fig.3E)

4. The assembly assistant handle is shown as Fig.3F

Fig.3A Fig.3B Fig.3C

Fig.3D Fig.3E Fig.3F

5.3ASSEMBLE THE MIDDLE TUBE FOR PT 25 LH (DYM246406)

1. Pull out the positioning pin and fix the middle tube to the head. Remember the installation hole should be

faced to positioning pin in order to fix securely. (Fig.4A/ Fig.4B/ Fig.4C)

2. Rotate the locking knob(turn clockwise)to fix the tube firmly. (Fig.4D)

Fig.4A Fig.4B

Limit block

Limit slot

Positioning pin

Installation hole

13

Fig.4C Fig.4D

6. MOUNTING THE PROTECTOR

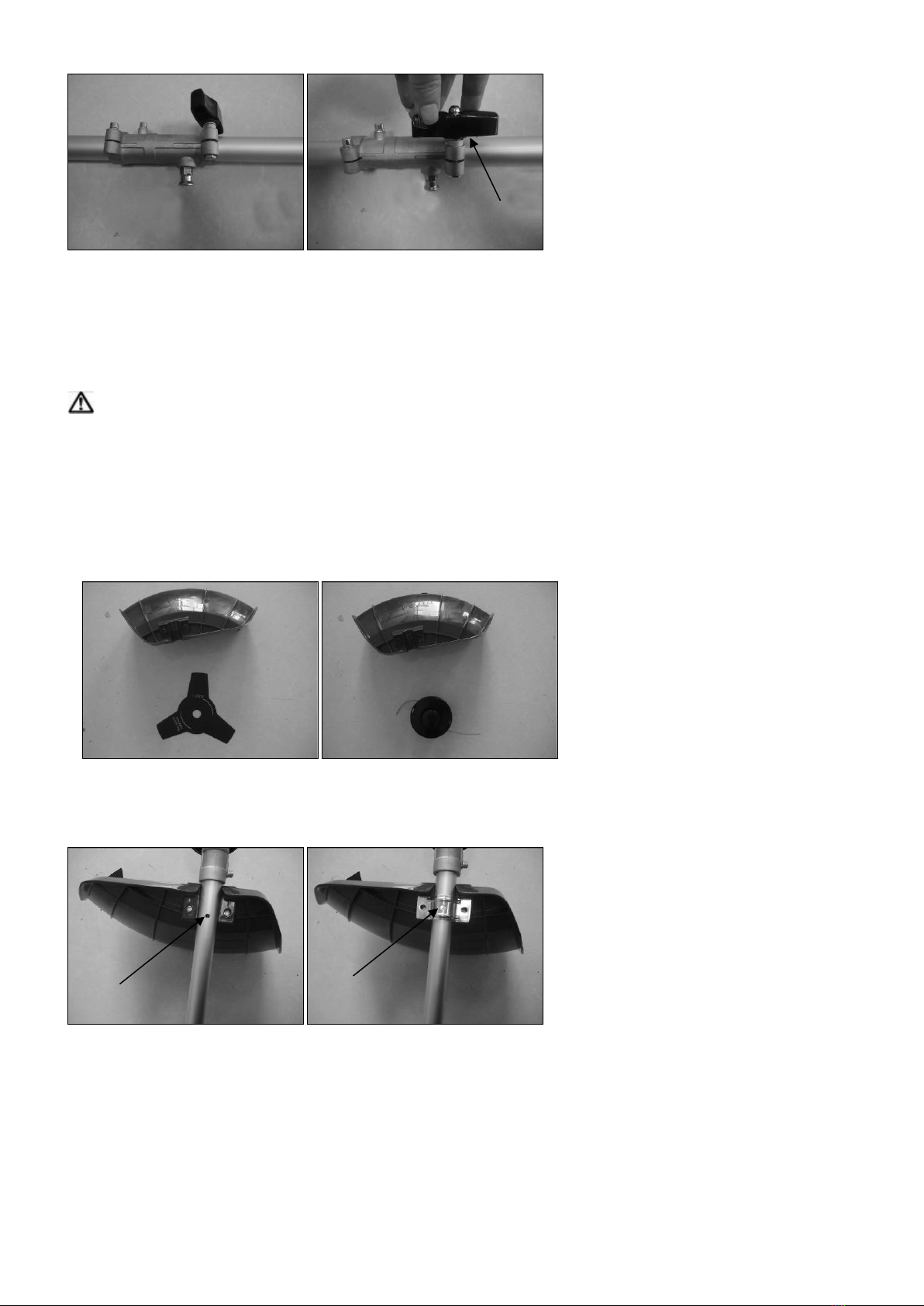

For PBC 33 BH/PBC 32 B (DYM246601) and PBC 43 BH/PBC 42 B (DYM246801)

CAUTION: To meet the applicable safety provisions, you must only use the tool/ protector combinations

indicated in Fig.5A/Fig.5B. Always use genuine original cutter blades or nylon cutting head.

1. The cutter blade must be well polished, and free of cracks or breakage. If the cutter blade hits against a

stone during operation, stop the engine and check the blade immediately.

2. Polish or replace the cutter blade every three hours of operation.

3. If the nylon cutting head hits against a stone during operation, stop the engine and check the nylon cutting

head immediately.

Fig.5A Fig.5B

4. Place the clamp matching the hole of the shaft. (Fig.5C/Fig.5D)

5. Fix the protector to the clamp with two bolts. (Fig.5E/Fig.5F)

Fig.5C Fig.5D

Nylon cutting head

Cutter blade

Protector

Protector

Clamp

Hole

Locking knob

14

Fig.5E Fig.5F

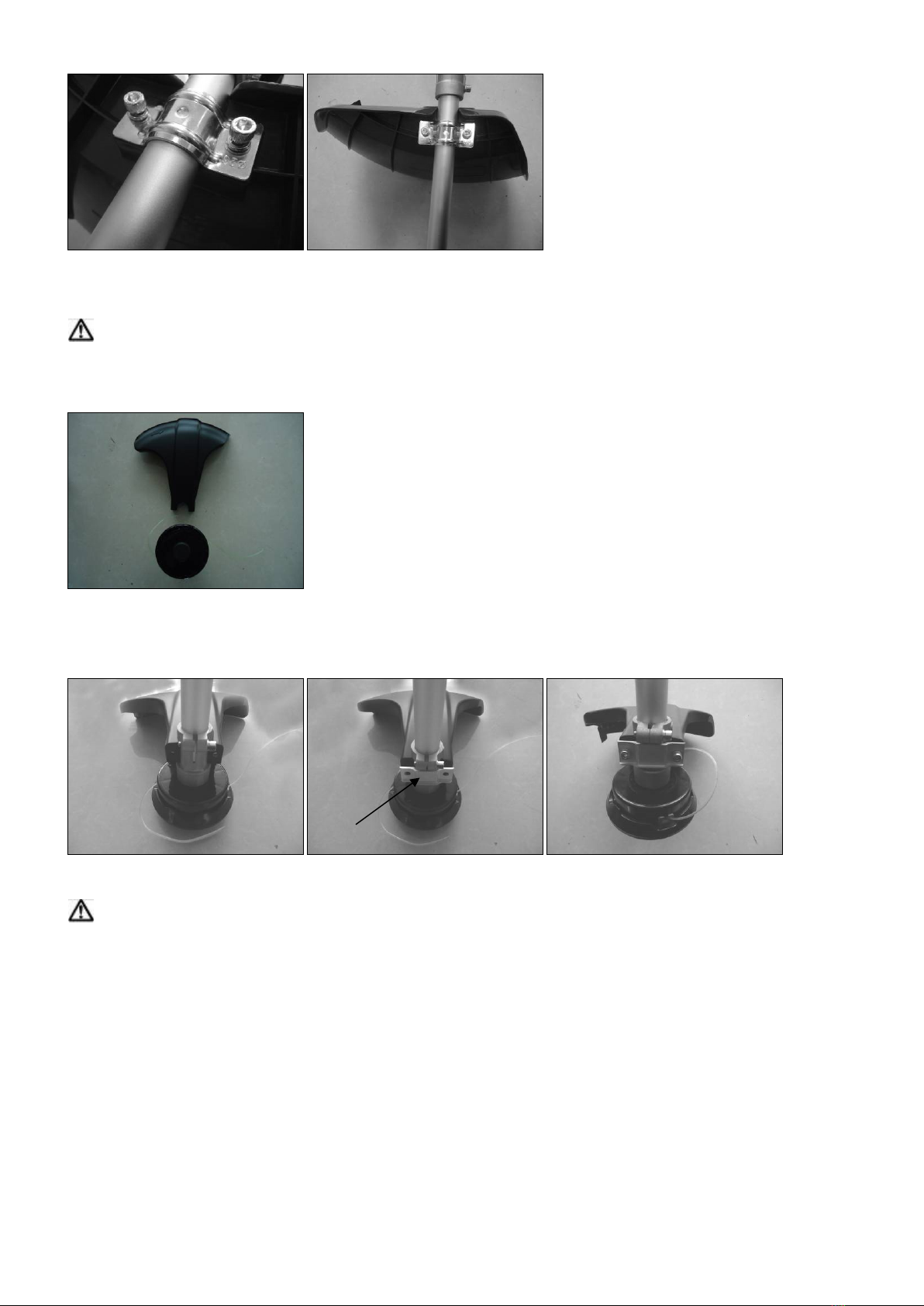

For PT 25 LH (DYM246406)

CAUTION: To meet the applicable safety provisions, you must only use the tool/ protector combinations

indicated in Fig. 6A. Always use genuine original nylon cutting head. If the nylon cutting head hits against a

stone during operation, stop the engine and check the nylon cutting head immediately.

Fig.6A

1. Place the clamp matching the protector. (Fig.6B/Fig.6C)

2. Fix the protector to the clamp with two bolts. (Fig.6D)

Fig.6B Fig.6C Fig.6D

CAUTION: The appropriate protector must always be installed, for your own safety and in order to comply

with accident-prevention regulations. Operation of the equipment without the guard installed is prohibited.

7. MOUNTING THE CUTTER BLADE / NYLON CUTTING HEAD

Only for PBC 33 BH/PBC 32 B (DYM246601) and PBC 43 BH/PBC 42 B (DYM246801)

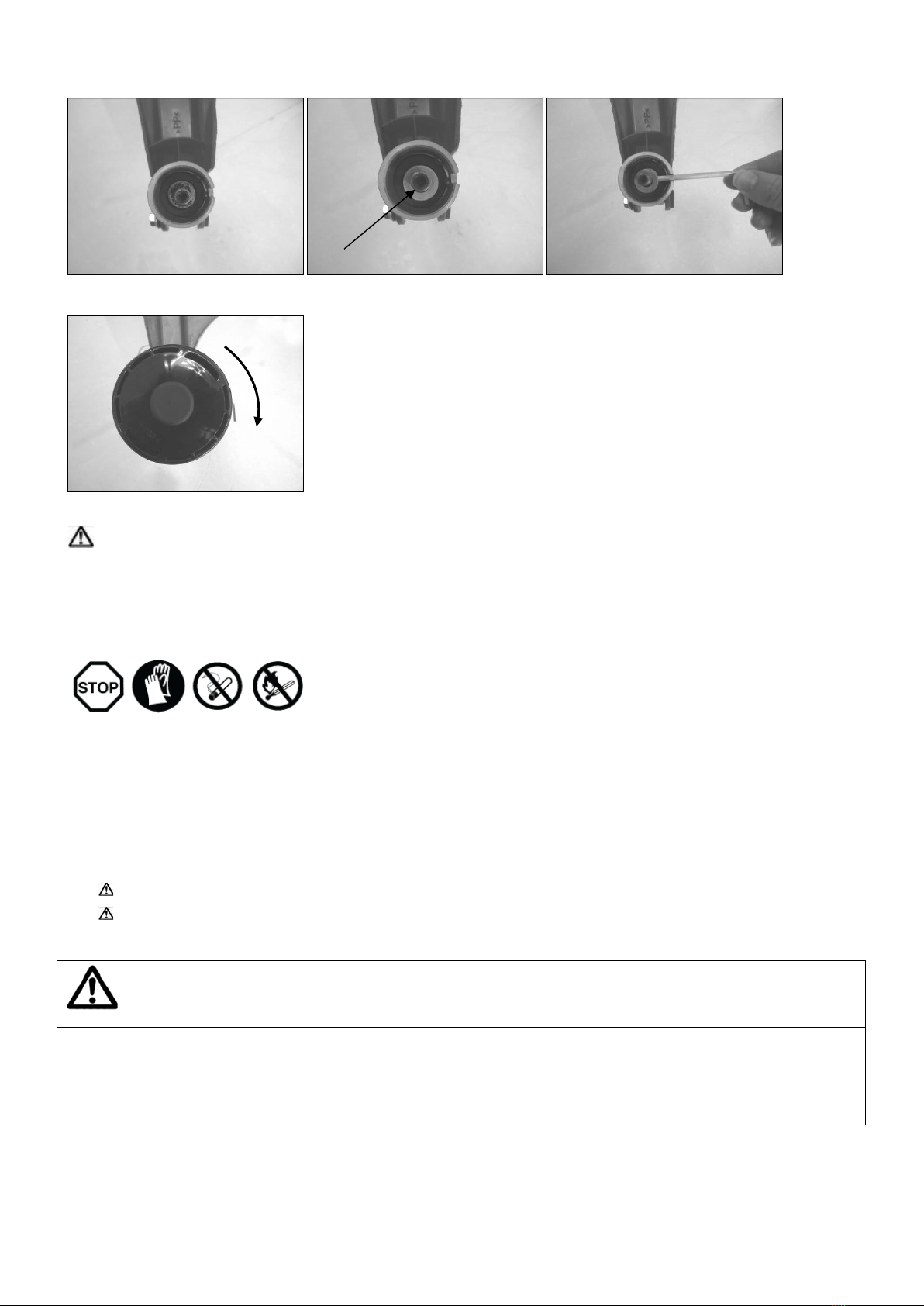

The cutter blade

1. The cutter blade or nylon cutting head can be replaced easily by first turning the equipment upside

down.(Fig.7A)

2. Put the washer into place and insert the hex wrench through the hole in the gear case.(Fig.7B/Fig.7C)

3. Put the cutting blade, receiver washer, clamp washer, nut into place.(Fig.7D/Fig.7E/Fig.7F/Fig.7G)

Nylon cutting head

Protector

Clamp

15

4. Tighten the nut anti-clockwise as the arrow shows. (Fig.7H)

Fig.7A Fig.7B Fig.7C

Fig.7D Fig.7E Fig.7F

Fig.7G Fig.7H

The nylon cutting head

1. With the hex wrench still in place (Fig.7I).

2. Screw the nylon cutting head onto the shaft anti-clockwise as the arrow shows (Fig.7J).

Fig.7I Fig.7J

NOTE: Always wear gloves when handling the cutter blade.

For PT 25 LH (DYM246406)

The nylon cutting head

1. Turning the equipment upside down. (Fig.8A)

2. Put the washer into place. (Fig.8B)

3. Insert the hex wrench through the hole in the gear case. (Fig.8C)

16

4. Screw the nylon cutting head onto the shaft clockwise as the arrow shows (Fig.8D)

Fig.8A Fig.8B Fig.8C

Fig.8D

NOTE: Always wear gloves when handling the cutter blade.

8. FUELS/REFUELING

Handling fuel

Utmost care is required when handling fuel. Fuel may contain substances similar to solvents. Refuel either in

a well ventilated room or outdoors. Do not inhale fuel vapors, avoid any contact of fuel or oil with your skin.

Mineral oil products degrease your skin. Prolonged skin contact with these products will cause your skin to

become extremely dry, which may result in various kinds of skin disease. In addition, allergic reactions may

occur.

Eyes can be irritated by contact with oil. If oil comes into your eyes, immediately wash them with clear water.

If your eyes are still irritated, see a doctor immediately.

Refueling

CAUTION: The engine must be switched off.

CAUTION: Add mixture of gasoline and engine oil, the ratio of gasoline and engine oil is 40 to

1

fuel & oil ratio/ quality

The engine of your brush cutter/ line trimmer has got to be operated with a mixture of fuel and oil. The quality

of those two operating materials is decisive for a proper function and a long lifetime of the engine. Inadequate

fuel, oil or mixture ratio will lead to serious damages to the engine, i. e. piston seizure, premature wear, ASO).

The correct mixture ratio is (fuel:oil) 40:1.

Washer

17

Only use quality fuel with min. octane rating 90 ROZ.

Only use quality oil for two stroke engines fulfilling the API TC specification.

Damages resulting from usage of wrong fuel, oil or fuel/oil ratio are not subject to warranty.

Thoroughly clean the area around the fuel filler cap (2), to prevent dirt from getting into the fuel tank (1).

(Fig.9)

1. Unscrew the fuel filler cap (2) and fill the tank with fuel.

2. Tightly screw on the fuel filler cap (2).

3. Clean screw fuel filler cap (2) and tank after refueling.

Fig.9

Storage of Fuel

Fuel cannot be stored for an unlimited period of time. Only use approved fuel storage containers.

9. MOUNTING THE SHOULDER STRAP

PT 25 LH (DYM246406) equips with single shoulder strap, PBC 32 B (DYM246601)equips with single

shoulder strap and PBC 33 BH (DYM246601)equips with double shoulder strap, PBC 43 BH/PBC 42 B

(DYM246801) equips with double shoulder strap.

For PT 25 LH (DYM246406) and PBC 32 B (DYM246601)

1. Sets the strap to the body. (Fig.10A)

2. Lock the hanger into the hole of the support (Fig.10B/Fig.10C).

3. Adjust the strap length so that the cutter blade will be kept parallel with the ground.(Fig.10D/Fig.10E)

4. In case of emergency, pull the string quickly, and detach the equipment (Fig.10F/Fig.10G/Fig.10H). Be

extremely careful to maintain control of the equipment at this time. Do not allow the equipment to be deflected

toward you or anyone in your vicinity.

WARNING: Failure to maintain complete control of the machine at all could result in serious injury or

death.

40:1 mixture table fuel oil

1000 ml 975 ml 25 ml

600 ml 585 ml 15 ml

18

Fig.10A Fig.10B Fig.10C

Fig.10D: PT 25 LH (DYM246406) Fig.10E: PBC 32 B (DYM246601) Fig.10F

Fig.10G Fig.10H

For PBC 33 BH (DYM246601) and PBC 43 BH/PBC 42 B (DYM246801)

1. Adjust the main strap to your body. (Fig.11A)

2. Insert the part A to the part B for locking (Fig.11B/Fig/11C). The front view and rear view were shown as

Fig. 11D/Fig.11E/Fig.11F/Fig.11G

3. Lock the hanger into the hole of the support (Fig.11H/Fig.11I).

4. Adjust the strap length so that the cutter blade will be kept parallel with the ground.(Fig.11J)

5. In case of emergency, pull the string quickly, and detach the equipment (Fig.11K/Fig.11L/Fig.11M). Be

extremely careful to maintain control of the equipment at this time. Do not allow the equipment to be deflected

toward you or anyone in your vicinity.

WARNING: Failure to maintain complete control of the machine at all could result in serious injury or

death.

Fig.11A Fig.11B Fig.11C

19

Fig.11D Fig.11E Fig.11F

Fig.11G Fig.11H Fig.11I

Fig.11J Fig.11K Fig.11L

Fig.11M

10. IMPORTANT OPERATING POINTS/STOPPING THE CUTTER/TRIMMER

Observe the applicable accident prevention regulations.

Starting

Move at least 3 m away from the place of refueling. Place the brush cutter on a clean piece of ground taking

care that the cutting tool does not come into contact with the ground or any other objects.

1. First place the machine on the ground.

2. Give a gentle push on the primer pump repeatedly (10 times) until fuel comes into the primer pump.

(Fig.12A)

3. Push the choke lever to the close position. (Fig.12B)

4. Slowly pull the starter grip until resistance is felt and continue with a smart pull. Do not pull out the starter

rope to its full extent and do not allow the starter handle to be retracted without control. Maintain control of the

starter rope and ensure it retracts slowly.(Fig.12C)

5. Repeat the starting operation until you hear the engine’s initial ignitions.

6. When starting cool engine, turn choke lever to “on” position. (Fig.12D)

7. Run the engine for approximately one minute at a moderate speed before applying full throttle.

20

Fig.12A Fig.12B

Fig.12C Fig.12D

Note: If the starter handle is pulled repeatedly when the choke lever remains at “on” position, the engine

will not start easily due to excessive fuel intake.

In case of excessive fuel intake, remove the spark plug and pull the starter handle slowly to remove excess

fuel. Also, dry the electrode section of the spark plug.

CAUTION: Always reduce the engine revolutions when the equipment is not being used for work.

Operating the equipment at high revolutions when not being used for work will shorten the lifespan of the

equipment.

For PBC 33 BH/PBC 32 B (DYM246601) and PBC 43 BH/PBC 42 B (DYM246801)

Cold start

1. Push the I-O switch (1) to “I” position.(Fig.13)

2. Grasp the handle (hand pressure activates the safety lock-off lever (2)).

3. Press the throttle lever (3) and hold it down.

4. Press the lock button (4) and release the control lever, and then release the lock button (the lock button

holds the throttle lever in the start-up position).

1

2

4

3

Primer pump

Choke lever

This manual suits for next models

7

Table of contents