FS 40, FS 40 C, FS 50, FS 50 C

English

4

In vehicles: Properly secure your power

tool to prevent turnover, fuel spillage and

damage.

Fueling

Always shut off the engine before

refueling.

Do not fuel a hot engine – fuel may spill

and cause a fire.

Open the fuel cap carefully to allow any

pressure build-up in the tank to release

slowly and avoid fuel spillage.

Fuel your power tool only in well-

ventilated areas. If you spill fuel, wipe

the machine immediately – if fuel gets on

your clothing, change immediately.

Your power tool comes standard with

either a screw-type or bayonet-type fuel

cap.

This reduces the risk of unit vibrations

causing the fuel cap to loosen or come

off and spill quantities of fuel.

To reduce the risk of serious or fatal

burn injuries, check for fuel leakage. If

fuel leakage is found, do not start or run

the engine until leak is fixed.

Before Starting

Check that your power tool is properly

assembled and in good condition – refer

to appropriate chapters in the instruction

manual.

–Check the fuel system for leaks,

paying special attention to visible

parts such as the tank cap, hose

connections and the manual fuel

pump (on machines so equipped). If

there are any leaks or damage, do

not start the engine – risk of fire.

Have your machine repaired by a

servicing dealer before using it

again.

–Use only an approved combination

of cutting attachment, deflector,

handle and harness. All parts must

be assembled properly and

securely. To reduce the risk of

injury, never use metal cutting

attachments.

–The stop switch must move easily to

0.

–Check smooth action of choke

knob, throttle trigger lockout and

throttle trigger – the throttle trigger

must return automatically to the idle

position. The choke lever must

spring back from the g and <

positions to the run position F when

the throttle trigger lockout and

throttle trigger are squeezed.

–Check that the spark plug boot is

secure – a loose boot may cause

arcing that could ignite combustible

fumes and cause a fire.

–Check cutting attachment for

correct and secure assembly and

good condition.

–Check protective devices (e.g.

deflector for cutting attachment) for

damage or wear. Always replace

damaged parts. Never operate the

unit with a damaged deflector.

–Never attempt to modify the controls

or safety devices in any way.

–Keep the handles dry and clean –

free from oil and dirt – for safe

control of the power tool.

–Adjust the harness and handle(s) to

suit your height and reach.

To reduce the risk of accidents, do not

operate your power tool if it is damaged

or not properly assembled.

If you use a shoulder strap or full

harness: Practice removing and putting

down the power tool as you would in an

emergency. To avoid damage, do not

throw the machine to the ground when

practicing.

Starting the Engine

Start the engine at least 3 meters from

the fueling spot, outdoors only.

Place the unit on firm ground in an open

area. Make sure you have good balance

and secure footing. Hold the unit

securely. The cutting attachment must

be clear of the ground and all other

obstructions because it may begin to run

when the engine starts.

Gasoline is an extremely

flammable fuel. Keep

clear of naked flames. Do

not spill any fuel – do not

smoke.

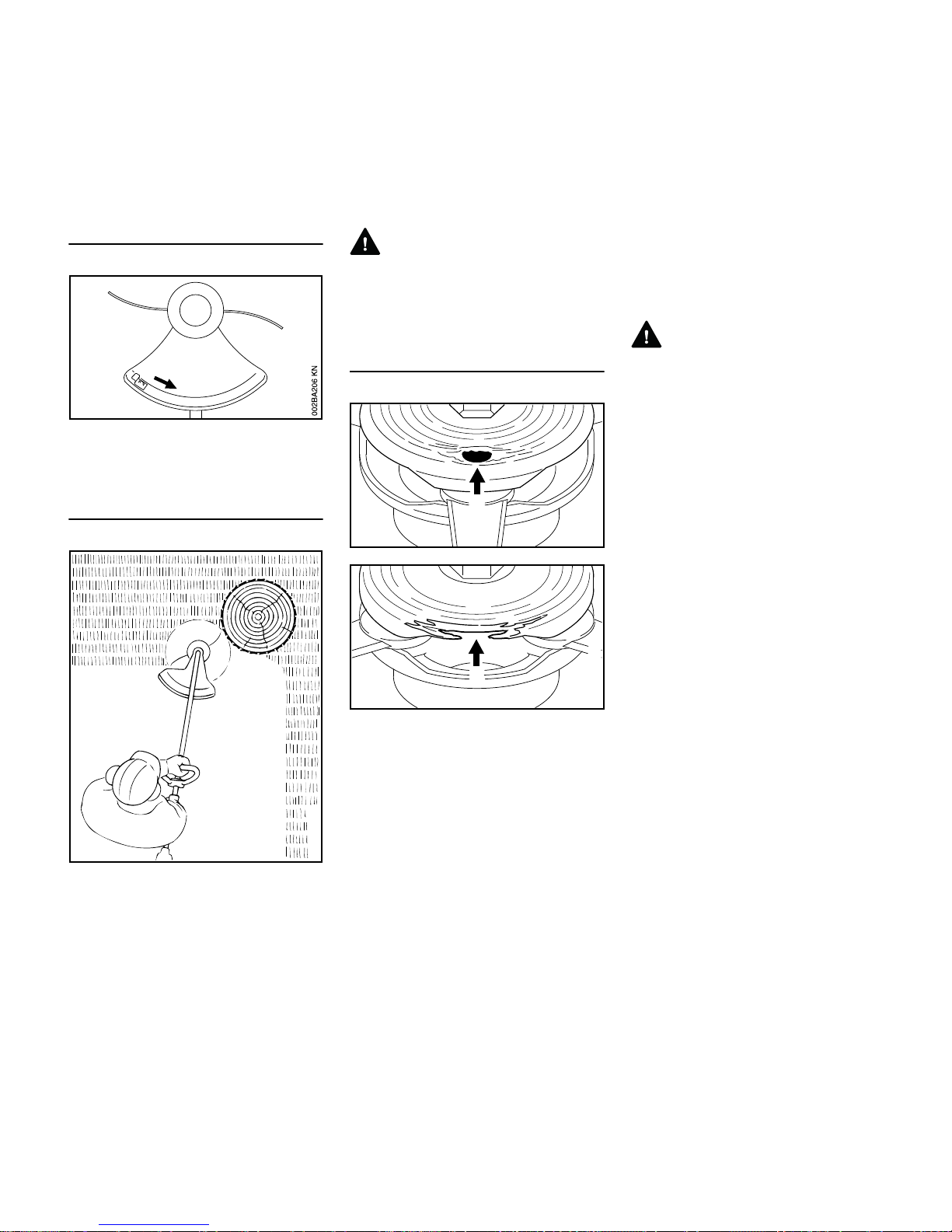

After fueling, tighten

down the screw-type fuel

cap as securely as

possible.

After fueling, insert the

fuel cap with hinged grip

(bayonet-type cap) cor-

rectly in the opening, turn

it clockwise as far as stop

and fold the grip down.