MPI Himax HC3514-2900 User manual

Operation:

1. Himax Brushless motors require brushless sensorless speed

controls. Failure to use a brushless sensorless electronic

speed control (ESC) can result in damage to the motor and/or

ESC. A Castle Creations Phoenix ICE series ESC is recom-

mended for best performance. The standard setting for tim-

ing advance is recommended and PWM rate should be

changed to 16Khz for best operation. For correct RPM log-

ging, set the motor poles to 14.

2. The three wires of the motor can be connected to the three

output leads of the ESC in any order. Check the direction of

rotation of the motor. If the motor spins in the wrong direction

switching any two of the motor wires will reverse rotation. Be

sure to insulate the wires to prevent shorting which may dam-

age the ESC.

3. Do not shorten the motor wires. Shortening or cutting the

motor wires voids the warranty and may cause motor failure. If

the supplied connectors are not to be used, remove them by

desoldering. DO NOT CUT THE CONNECTORS OFF!

4. Allow for proper cooling of the motor during operation. With

extremely high capacity batteries, care must be taken to pre-

vent excessive motor temperature. Overheating of the motor

is not covered under warranty. Insufficient cooling can result in

overheated motors, even when operated at moderate power

levels.

5. Do not disassemble the motor. Disassembling the motor voids

the warranty. If service is required please return the unit to

Maxx Products for service.

6. Install the propeller after proper rotation has been determined.

Consult the ESC operation manual for proper arming and use

procedures. Be sure the prop is clear before starting the mo-

tor. Once the battery is plugged in stay clear of the prop, elec-

tric motors are capable of extremely high torque and can be

very dangerous.

7. Verify the current draw. Excessive current draw will overheat

and damage the motor. Overheating is not covered under war-

ranty. The current must be within limits at full throttle. Verify

the power consumption. Certain setups will run into the power

limit before the current limit. Observe the current and power

limits, which ever comes first. The 15-second max current rat-

ing is for limited motor run applications. Excessive use at

high throttle settings when set up for the 15 second rating will

overheatthemotor. Allowforadequatecoolingbetweenbursts.

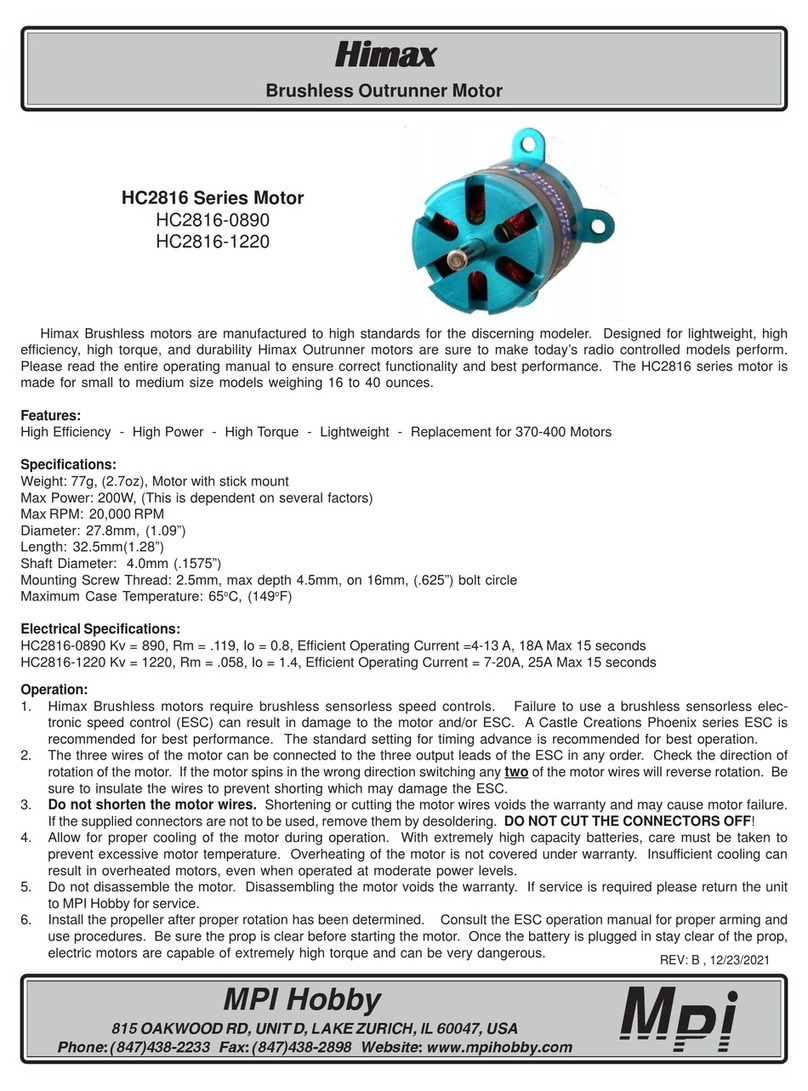

Himax Brushless motors are manufactured to high standards

forthediscerningmodeler. Designed for lightweight, high efficiency,

hightorque,anddurabilityHimaxOutrunnermotorsaresureto make

today’s radio controlled models perform. Please read the entire

operating manual to ensure correct functionality and best perfor-

mance. The HC3514-2900 motor is specially designed for the

MuliPlex Fun-Jet Ultra prop-jet model weighing 31oz. or any high

speed model weighing 20-40 oz.

Accessories (included):

1 - Prop Adapter

3 - Female 3.5mm connector

4 - Motor Mounting Screws

1 - Motor Mount Kit

3 - Hex Keys

Features:

High Efficiency - High Power - High Torque - Lightweight

Specifications:

Weight: 103g, (3.63oz), Motor only

Max Power: 800W, (This is dependent on several factors)

MaxRPM: 40,000 RPM

Diameter: 35.2mm, (1.39”)

Length: mm, 38mm(1.5”)

Shaft Diameter: 4.0mm (5/32”)

Mount Screws: M3, max depth 5mm, on 25mm, (1.0”) circle

Maximum Case Temperature: 65oC, (149oF)

Electrical Specifications:

HC3514-2900 Kv = 2900, Rm = .0076, Io = 4.8

Efficient Operating Current = 25-80A, 90A Max 15 seconds

Recommended Accesories:

75 or 100 Amp Brushless Speed Control (depending on propeller

used)

7.4-11.1V Lithium Polymer Battery, capable of 90-100 Amps, Use

of 14.8 volt (4S) Lithium Polymer battery will void the warranty

MAXX PRODUCTS INTERNATIONAL, INC.

815 OAKWOOD RD, UNIT D, LAKE ZURICH, IL 60047, USA

Phone: (847)438-2233 Fax: (847)438-2898 Website: www.maxxprod.com

REV: _ , 09/19/2012

Himax Brushless Outrunner Motor W/ Cooling Fan

HC3514-2900

Choosing a power system:

Power system can be chosen based on the type of flying ex-

pected of the model and all up weight of the aircraft. Sedate flying

from a hand launch requires 35 watts per pound(W/Lb). Taking off

the ground needs approximately 50W/Lb. Aerobatics and good

climb performance, 75W/Lb. Anything more than 75W/Lb will

result in excellent performance. Based on the weight of the model

and the flying desired, the power require can be calculated. Se-

lect the voltage of the battery being used. It is best to use a loaded

voltage of about 98% of nominal. Now, calculate the current re-

quired. From the chart, pick a motor at the voltage you intend to

use and find the prop that pull the required current.

Propeller selection:

Use the chart to start with propeller selection. It is a starting

point. If you intend to use different props or battery voltage we

recommend testing several setups and make sure to Verify cur-

rent draw when testing. Failure to do so may damage the

motor and will void the warranty. Different models use differnt

props. Most sport models will use a prop with a P/D or 0.6-0.8.

Models that are designed to fly at high speed or have other spe-

cial requirements will use props in the 1.0 P/D range. The high-

est static thrust will be available from the 0.6 P/D props, but they

have limited top speed. Highest speeds can be attained with 1.0

P/D props, however low speed thrust and acceleration is limited.

Warranty:

Himax motors have a two year limited warranty to the original

owner, excluding gearboxes. All motors are guaranteed to be free

from manufacturing defects within two years of date of purchase.

Not covered under warranty is crash damage, customer abuse,

improper use, or overheating. Note use of 4 cell LiPo would

constitute Improper Use. Warranty claims should be handled

directly with Maxx Products, 815 Oakwood Rd, Unit D, Lake Zurich,

IL 60047. Be sure to include contact information and a descrip-

tion of the problem including which ESC, battery, and prop was

being used. If possible visit www.maxxprod.com to obtain a ser-

vice form.

Service:

Himax motors in need of service should be sent to Maxx

Products, 815 Oakwood Rd, Unit D, Lake Zurich, IL 60047.

Please include a note explaining the problem. Return shipping

for repair estimates must be prepaid.

Reversing the Shaft:

1.First of all, never use a hammer or heavy object to pound or tap

on the motor. Sharp impact will damage ball bearings and other

components.

2.Use an alen wrench to remove the setscrews in the endbell

(fan rotor). The setscrews may be tight because thread locker

is used to secure them. Heating with a heat gun will soften the

thread locker. Then move the snap ring to the outer groove.

3.In order to maintain critical balance, the shaft fits tightly in the

rotatingendbell. Use an arborpress or drill pressto exert steady

pressure to push it through endbell. Before applying pressure,

make sure the press and shaft are aligned. Avoid using a vise

because it is difficult to maintain proper alignment with a vise.

Press through until there is just light pressure against the

snap ring. Too much pressure will damage the bearings.

4.There are flats on the shaft. Align the flats with the set screws,

and tighten. If you wish to use thread locker, use only a

removable type and use sparingly.

Removing the Shaft:

1.Follow procedure as above except REMOVE the snap ring.

2.Separate the stator assembly and rotor assembly. This may

be tight because thread locker sometimes seeps between the

shaft and ball bearing. Press out the old shaft (see #3 above)

then press in the new shaft.

3.There are flats on the shaft. Align the flats with the set screws,

and tighten.

6.Put the rotor and stator assemblies back together and reinstall

the snap ring. If you wish to use thread locker, use only a

removable type and use sparingly.

Maintenance:

Brushless motors are almost maintenance free, so minimal

care is required for long life. Keep the motor clean free of dust

and dirt, especially the bearings. Dirty bearings wear quickly.

Lubricate the bearings regularly with light oil. Do not immerse

the motor in water, or solvents. Do not bend the wires excessively

and secure wires to prevent breakage due to fatigue from vibra-

tion. Always used balanced propellers to reduce loads on bear-

ings, to reduce noise, and reduce stress on the airframe.

Reading the Chart

The graph represents the HC3514-2900

operating range. Current ratings are noted

on the front of this manual. The suggested

props are not a recommendation for any

specific airframe or flying style. The graph

does give a range of props to work with and

an idea of the current draw. The chart as-

sumesAPC Electric series propellers. First,

approximate the operating voltage, 1-1.1

volts per NiXx cell or 3.5 volts per Lithium

cell. As an example we are using an 3 cell

LiPo pack. 3 x 3.56= 10.8V. Follow along

the 10.8V line up the chart. If using a 6X5.5

propthis motor will draw approximately 74A.

This would be acceptable for full throttle

continuous flight on a small high speed

airframe. Note: this motor is designed to

use 2 or 3 cell LiPo. Use of a 4 cell LiPo

(over 12 volts) will void the warranty.

HC3514-2900 Current vs. Volgage with Propeller

0

10

20

30

40

50

60

70

80

6789101112

Voltage

Current

7x5 6x5.5 6x4 5.5x4.5

Other MPI Engine manuals