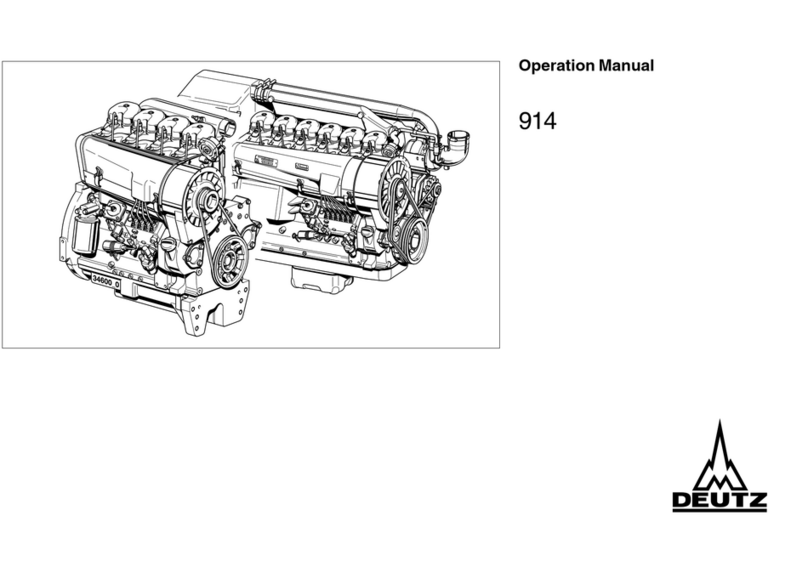

●Please read and observe the information

given in this Operation Manual. This will

enable you to avoid accidents, preserve the

manufacturer’s warranty and maintain the

engine in peak operating condition.

●This engine has been built exclusively for

the application specified in the scope of

supply, as described by the equipment manu-

facturer and is to be used only for the

intended purpose. Any use exceeding that

scope is considered to be contrary to the

intended purpose. The manufacturer will

not assume responsibility for any damage

resulting therefrom. The risks involved are

to be borne solely by the user.

●Use in accordance with the intended pur-

pose also implies compliance with the con-

ditions laid down by the manufacturer for

operation, maintenance and servicing. The

engine should only be operated by person-

nel trained in its use and the hazards in-

volved.

●The relevant accident prevention guidelines

and other generally accepted safety and

industrial hygiene regulations must be ob-

served.

●When the engine is running, there is a risk of

injury through:

- turning/hot components

- engines with positive ignition

- ignition systems (high electrical voltage)

You must avoid contact at all times!

●Unauthorized engine modifications will in-

validate any liability claims against the manu-

facturer for resultant damage.

Manipulations of the injection and regulating

system may also influence the performance

of the engine, and its emissions. Adherence

to legislation on pollution cannot be guaran-

teed under such conditions.

●Do not change, convert or adjust the cooling

air intake area to the blower.

The manufacturer shall not be held respon-

sible for any damage which results from

such work.

●When carrying out maintenance/repair op-

erations on the engine, the use of DEUTZ

original parts is prescribed. These are spe-

cially designed for your engine and guaran-

tee perfect operation.

Non-compliance results in the expiry of the

warranty!

●Maintenance and cleaning of the engine

should only be carried out when the engine

is switched off and has cooled down.

You must ensure that the electrical systems

have been switched off and the ignition key

has been removed.

Accident prevention guidelines concerning

electrical systems (e.g. VDE-0100/-0101/-

0104/-0105 Electrical protective measures

against dangerous touch voltage) are to be

observed.

When cleaning with fluids, all electrical com-

ponents are to be covered impermeably.

Safety guidelines / Accident prevention

00_GB.p65 04.02.2002, 14:232