2

Contents

Read Before Operating......................................................................................................................3

General Information..........................................................................................................................4

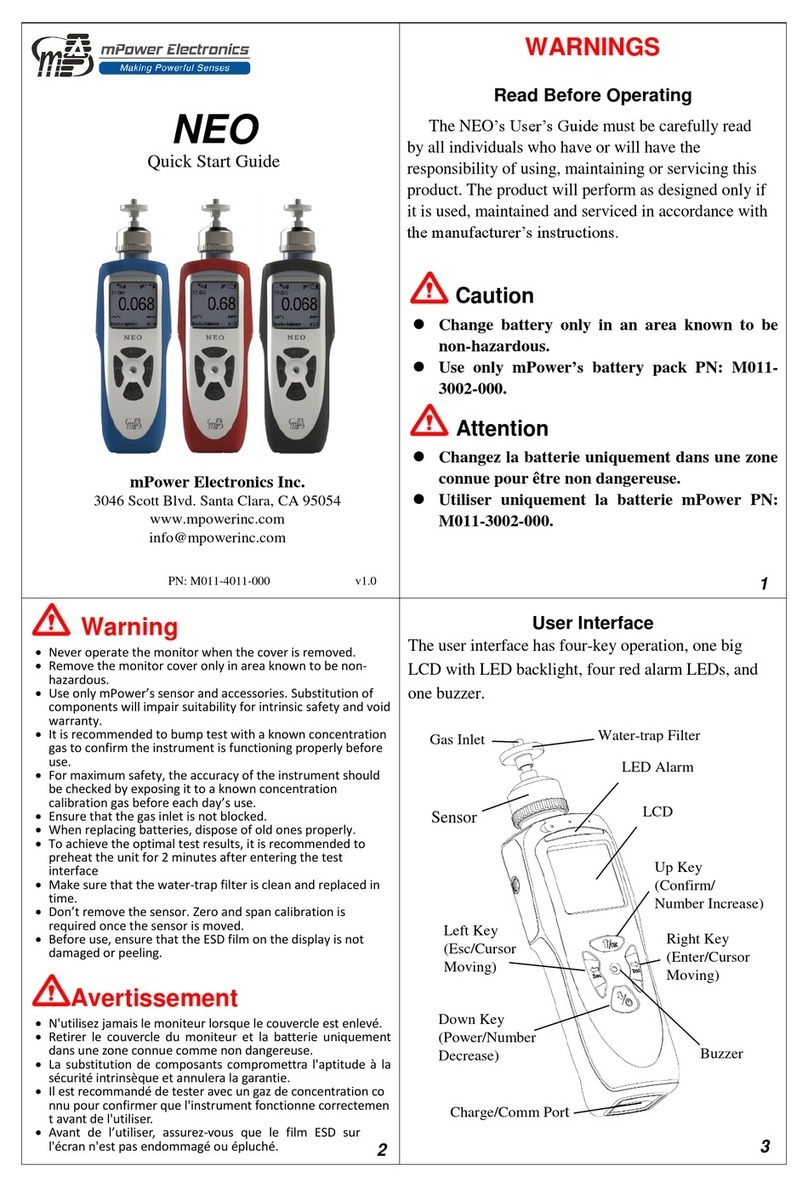

User Interface...................................................................................................................................5

Display .............................................................................................................................................6

Charging a Lithium-Ion Battery.......................................................................................................7

Low Voltage Warning..................................................................................................................7

Clock Battery................................................................................................................................7

Data Protection While Power Is Off ............................................................................................7

Instrument Basic Functions...............................................................................................................8

Turning The Instrument On..............................................................................................................8

Turning the Instrument Off ..............................................................................................................8

Integrated Sampling Pump...............................................................................................................8

Pump Status..................................................................................................................................9

External Water-trap Filter ................................................................................................................9

Alarm Signals...................................................................................................................................9

Alarm Signal Summary................................................................................................................9

Preset Alarm Limits & Calibration ............................................................................................10

Testing The Alarms....................................................................................................................10

Backlight ........................................................................................................................................10

Datalogging....................................................................................................................................10

Man Down......................................................................................................................................10

Wireless..........................................................................................................................................10

Operating Mode Overview..............................................................................................................11

VOC Mode Main Menu .................................................................................................................11

Benzene Tube Mode Main Menu...................................................................................................12

Benzene Tube Measurements.........................................................................................................12

STEL Measurement........................................................................................................................13

Benzene Tube Replacement...........................................................................................................14

Configuration Mode.........................................................................................................................15

Navigating Config Mode................................................................................................................15

Selection From a List .................................................................................................................15

Entering Numerical Values........................................................................................................15

Entering and Exiting Config Mode................................................................................................15

Config Mode Menus.......................................................................................................................16

Calibration..................................................................................................................................18

Measurement..............................................................................................................................20

Alarm Settings............................................................................................................................21

Datalog .......................................................................................................................................22

Monitor (Mnt) Setup ..................................................................................................................23

Computer Interface Using mPower Suite......................................................................................26

Connecting and Configuring..........................................................................................................26

Custom Gas (User Gas) in VOC Mode..........................................................................................28

Datalog Retrieval............................................................................................................................29

Real-time Data................................................................................................................................30

Maintenance......................................................................................................................................31

Cleaning or Changing PID Sensor/Lamp.......................................................................................31

Lamp Cleaning and Changing....................................................................................................31

Sensor Cleaning..........................................................................................................................32

Sampling Pump..............................................................................................................................32

Troubleshooting .............................................................................................................................33

Contact Information ........................................................................................................................34