VOXI User’s Guide

1

Contents

1. General Information ............................................................................................... 5

1.1 Key Features........................................................................................................................................................5

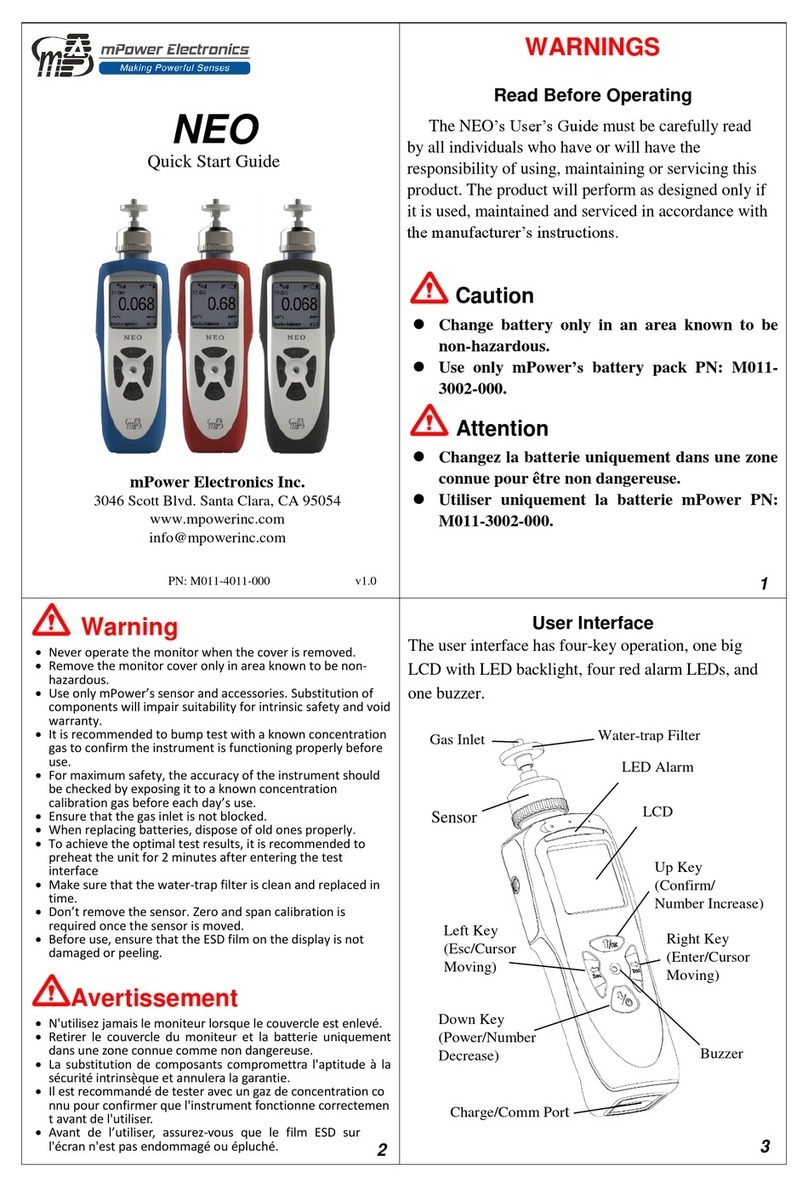

2. User Interface.........................................................................................................6

3. Installation .............................................................................................................7

3.1 Mounting ............................................................................................................................................................7

3.2 Rain Cap ..............................................................................................................................................................8

3.3 Electrical Connections .........................................................................................................................................9

3.3.1 Baseline 4 mA Signal Adjustment ..................................................................................................................10

3.3.2 MODBUS Message RTU Framing ...................................................................................................................10

4. Operation Overview ............................................................................................. 11

5. Controller Operations ........................................................................................... 11

5.1 Hardware and Software Requirements.............................................................................................................11

5.2 Connecting the VOXI to the Controller (Mobile Device)....................................................................................12

5.3 Operation Shortcut Buttons and Overview .......................................................................................................12

5.4 Field Service (Calibration, etc.)..........................................................................................................................13

5.5 VOXI Settings ....................................................................................................................................................16

5.6 View Operations Log.........................................................................................................................................17

6. Maintenance ........................................................................................................ 18

6.1 Replacing Filters................................................................................................................................................18

6.2 Removing/Cleaning/Replacing Lamp and Sensor .............................................................................................18

6.3 Replacing Pump ................................................................................................................................................20

7. Troubleshooting ................................................................................................... 21

8. Technical Specifications ........................................................................................ 22