Mpression Helio Board User manual

2015/11/16 © Mpression by Macnica Group

http://www.m-pression.com

Reference Manual

Mpression Helio Board

Revision 1.3

2015/11/16

Mpression Helio Board

2Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

© Mpression –Solutions by Macnica Group

Disclaimer

The information in this document (hereinafter called “Information”) is subject to change without notice.

Macnica Inc. (hereinafter called “Manufacturer”) makes no warranty of any kind regarding this document, or of

any liability arising out of the application or use of information in this document, and assumes no responsibility

for any errors that may appear in this document.

This document is distributed without any charge and reselling or copying without written authorization by

Manufacturer is restricted.

IN NO EVENT WILL MANUFACTURER BE LIABLE FOR ANY CONSEQUENTIAL, INDIRECT,

EXEMPLARY, SPECIAL, OR INCIDENTAL DAMAGES, INCLUDING ANY LOST DATA AND LOST

PROFITS, ARISING FROM OR RELATING TO YOUR USE OF THE INFORMATION, EVEN IF YOU HAVE

BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. THE TOTAL CUMULATIVE LIABILITY OF

MANUFACTURER IN CONNECTION WITH YOUR USE OF THE INFORMATION IN THIS DOCUMENT,

WHETHER IN CONTRACT OR TORT OR OTHERWISE, WILL IN NO EVENT EXCEED THE AMOUNT OF

FEES PAID BY YOU TO MANUFACTURER HEREUNDER FOR USE OF THE INFORMATION. YOU

ACKNOWLEDGE THAT THE FEES, IF ANY, REFLECT THE ALLOCATION OF RISK SET FORTH IN THIS

AGREEMENT AND THAT MANUFACTURER WOULD NOT MAKE AVAILABLE THE DESIGN TO YOU

WITHOUT THESE LIMITATIONS OF LIABILITY.

The Design is not designed or intended for use in the development of on-line control equipment in hazardous

environments requiring failsafe controls, such as in the operation of nuclear facilities, aircraft navigation or

communications systems, air traffic control, life support, or weapons systems (“High-Risk Applications”).

Manufacturer specifically disclaims any express or implied warranties of fitness for such High-Risk

Applications. You represent that use of the Design in such High-Risk Applications is fully at your risk.

Mpression Helio Board

Reference Manual - Mpression Helio Board 3

© Mpression by Macnica Group

Index

1. For Ensuring Safe Use __________________________________________________________ 5

1.1 Legend ....................................................................................................................................... 5

1.2 Cautions ..................................................................................................................................... 5

1.3 Manufacturer Information......................................................................................................... 7

2. Unboxing ____________________________________________________________________ 8

3. The Helio Board Hardware Descriptions ___________________________________________ 9

3.1 Overview.................................................................................................................................... 9

3.2 Key Components ........................................................................................................................ 9

3.3 Block Diagram .......................................................................................................................... 10

4. The Helio board Components___________________________________________________ 11

4.1 Board Overview ....................................................................................................................... 11

4.2 Featured Device: Cyclone V SoC .............................................................................................. 14

4.2.1 I/O Resources ............................................................................................................................14

4.3 JTAG Configuration................................................................................................................... 15

4.3.1 HPS debugging and FPGA Programming over On-board USB-Blaster II ....................................15

4.3.2 HPS debugging over Mictor connector for In-Circuit Emulator.................................................16

4.3.3 FPGA Programming over External USB-Blaster .........................................................................16

4.4 Status Elements ....................................................................................................................... 18

4.5 Setup Elements ........................................................................................................................ 19

4.5.1 JTAG settings DIP switch ...........................................................................................................19

4.5.2 HPS operation mode settings Jumper .......................................................................................20

4.5.3 HPS reset push button...............................................................................................................20

4.5.4 Program configuration push button..........................................................................................21

4.5.5 MSEL pins Settings ....................................................................................................................22

4.6 Clock Circuitry .......................................................................................................................... 23

4.6.1 On board Oscillators..................................................................................................................23

4.6.2 Off-board inputs / outputs ........................................................................................................24

4.7 General User Input / Output.................................................................................................... 25

4.7.1 User-Defined push button.........................................................................................................25

4.7.2 User-Defined DIP Switch ...........................................................................................................25

4.7.3 User-Defined LEDs.....................................................................................................................26

4.7.4 Character LCD............................................................................................................................26

4.7.5 Debug Header ...........................................................................................................................27

4.8 Components and Interfaces..................................................................................................... 28

4.8.1 10 / 100 / 1000 Ethernet...........................................................................................................28

4.8.2 HSMC.........................................................................................................................................29

4.8.3 USB2.0 OTG ...............................................................................................................................33

Mpression Helio Board

4Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

4.8.4 UART..........................................................................................................................................33

4.8.5 SD ..............................................................................................................................................34

4.8.6 I2C .............................................................................................................................................34

4.9 Memory ................................................................................................................................... 36

4.9.1 DDR3-SDRAM ............................................................................................................................36

4.9.2 QSPI Flash ROM.........................................................................................................................39

4.9.3 EEPROM ....................................................................................................................................39

4.10Power Supply ........................................................................................................................... 40

4.10.1 Power Distribution System........................................................................................................40

5. Document Revision History ____________________________________________________ 42

Mpression Helio Board

Reference Manual - Mpression Helio Board 5

© Mpression by Macnica Group

1. For Ensuring Safe Use

Be sure to follow the instructions given in this Manual which are intended to prevent harm to the

user and others as well as material damage.

1.1 Legend

Danger

Indicates an imminent hazardous situation which if not avoided will result in

death or serious injury.

Warning

Indicates a potentially hazardous situation which if not avoided could result in

death or serious injury.

Caution

Indicates a potentially hazardous situation which if not avoided may result in

minor or moderate injury or in property damage.

1.2 Cautions

Danger

Make sure to use the AC adapter (included in package) that is specified in this

Manual.

Using an AC adapter not meeting the specifications described in this Manual

will cause the kit to emit heat, explode, or ignite.

Warning

Do not apply strong impacts or blows to the kit.

Doing so may cause the kit to emit heat, explode, or ignite, or the equipment in

the kit to fail or malfunction. This may also cause fire.

Do not put the main unit or the AC adapter in cooking appliances such as

microwave ovens, or high-pressure containers.

Doing so might cause the main unit or AC adapter to emit heat, explode, ignite,

or emit smoke, or its parts to break or warp.

Do not wrap the main unit that is in use with cloth or other materials that are

likely to allow heat to build up inside the wrapping.

This will cause heat to build up inside the wrapping which may cause the main

unit to ignite or malfunction.

When disposing of the main unit, do not dispose of it along with general

household waste.

Throwing the main unit into fire may cause it to explode. Dispose of the

main unit following the laws, regulations, and ordinances governing

waste disposal.

Do not use the kit in places subject to extremely high or low temperatures or

severe temperature changes.

Doing so may cause the kit to fail or to malfunction.

Always be sure to use the kit in a temperatures ranging from 5°C to 35°C and a

humidity range of 0% to 85%.

Mpression Helio Board

6Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

Warning

(Continued from

previous page)

Do not pull the power supply cable with excessive force or place heavy items on

it.

Do not damage, break, bundle, or tamper with the power supply cable.

Damaged parts of the power supply cable might cause a short circuit resulting

in fire or accidents involving electrical shock.

Do not unplug the power plug with wet or moist hands.

This might cause injuries or equipment malfunctions or failures due to

electrical shock.

Plug the power plug securely into the outlet.

If the power plug is not securely plugged into the outlet, it may cause accidents

involving electrical shock or fire due to heat emitted.

Do not connect many electrical cords to a single socket or connect an AC adapter

to an outlet that is not rated for the specified voltage.

Failing to do so may cause the equipment to malfunction or fail, or lead to

accidents involving electrical shock or fire due to heat emitted.

Periodically remove any dust accumulated on the power plug and around the

outlet (socket).

Do not use a power plug with dust accumulated on it because doing so will lead

to insulation failure due to moisture which may lead to fire.

Remove any dust on the power plug and around the outlet with dried cloth.

Do not place any containers such as cups or vases filled with water or other

liquid on this Board.

If this Board is exposed to water or other liquids it may cause the Board to

malfunction or lead to accidents involving electrical shock. If you spilled water

or other liquid on this Board, immediately stop using the Board, turn off the

power, and unplug the power plug. If you have any requests for repairs or

technical consultation, please contact the Manufacturer.

Caution

Do not place the kit on unstable places such as shaky stands or tilted locations.

Doing so may cause injuries or cause this Board to malfunction if the Board

should fall.

Do not attempt to use or leave the kit in places subject to strong direct sunlight

or other places subject to high temperatures such as in cars in hot weather.

Doing so might cause the kit to emit heat, break, ignite, run out of control,

warp, or malfunction.

Also, some parts of the equipment might emit heat causing burn injuries.

Unplug the power supply cable when carrying out maintenance of devices in

which the main unit is embedded.

Failure to do so may lead to accidents involving electrical shock.

Do not place this Board in locations where excessive force is applied to the

Board.

Failure to do so may cause the PC board to warp, leading to breakage of the PC

board, missing parts or malfunctioning parts.

When using the kit together with expansion boards or other peripheral devices,

be sure to carefully read each of their manuals and to use them correctly.

Manufacturer does not guarantee the operation of specific expansion boards or

peripheral devices when used in conjunction with this Board unless they are

specifically mentioned in this Manual or their successful operation with this

Caution

(Continued from

previous page)

Mpression Helio Board

Reference Manual - Mpression Helio Board 7

© Mpression by Macnica Group

Board has been confirmed in separate documents.

Be sure to turn off the power switch when moving this Board to connect to other

devices.

Failure to do so may cause this Board to fail or lead to accidents involving

electrical shock.

Do not clean this Board by using a rag containing chemicals such as benzine or

thinner.

Failure to do so will likely to cause this Board to deteriorate. When using a

chemical cloth be sure to comply with any directions or warnings.

Do not immediately turn on the power if you find that water or moisture had

condensed onto the main unit after removing the board from the package.

Condensation might occur on this Board when taking it out of the box, if the

board is cool yet the room temperature is warm.

Do not apply power to the Board while water or moisture has condensed on it

because the moisture may cause the Board to break or may shorten the service

life of the parts.

When you first take this Board out of the box be sure to leave it at room

temperature for a while before using it. If condensation or moisture has

occurred on this Board, first wait for the moisture to fully evaporate before

installing or connecting the Board to other devices.

Do not disassemble, dismantle, modify, alter, or recycle parts unless they are

clearly described as customizable in this Manual.

Although this kit is customizable, if parts not specified in this Manual as

customizable are modified in any way, then the overall product operation

cannot be guaranteed.

Please consult with Manufacturer beforehand if you wish to customize or modify

any parts that are not described in this Manual as customizable.

1.3 Manufacturer Information

The Manufacturer of this product is:

Macnica, Inc. | Strategic Technology Group

Mpression

1-6-3 Shin-Yokohama, Kouhoku-ku, Yokohama, 222-8561 Japan

http://www.m-pression.com

Please contact through web site.

Mpression Helio Board

8Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

2. Unboxing

Package Components

This product consists of the following board and peripherals. Please make sure all components

listed below are included.

Table 2-1-1. Packing list

Customer letter

The Helio board

microSD card

USB Standard-A to Mini-B plug cable

AC adaptor (Output 12V/3.8A)

This Reference Manual

Download these files from Web site

described in the Customer letter.

The Helio board circuit diagram

FPGA sample design

If there is any question or doubt about the packaged product, contact your local distributor.

Mpression Helio Board

Reference Manual - Mpression Helio Board 9

© Mpression by Macnica Group

3. The Helio Board Hardware

Descriptions

3.1 Overview

This document describes the hardware features of the Helio board, including the detailed pin-out

and component reference information required to create custom FPGA designs that interface with

all components of the board.

Main CORE of the Helio board is Altera®Cyclone®V SoC. Altera Cyclone V SoC include the Hard

Processor System (HPS) with integrated ARM®Cortex™-A9MPCore processor.

One High-speed Mezzanine Card (HSMC) connector is available to add additional functionalities

via a variety of HSMCs available from various partners.

For more information on the following topics, refer to the respective documents:

As for Cyclone V device family, refer to the Cyclone V Device Handbook.

For HSMC Specification, refer to the High Speed Mezzanine Card (HSMC) Specification.

3.2 Key Components

The Helio board features the following key component blocks:

Key components are listed in Table 3-2-1.

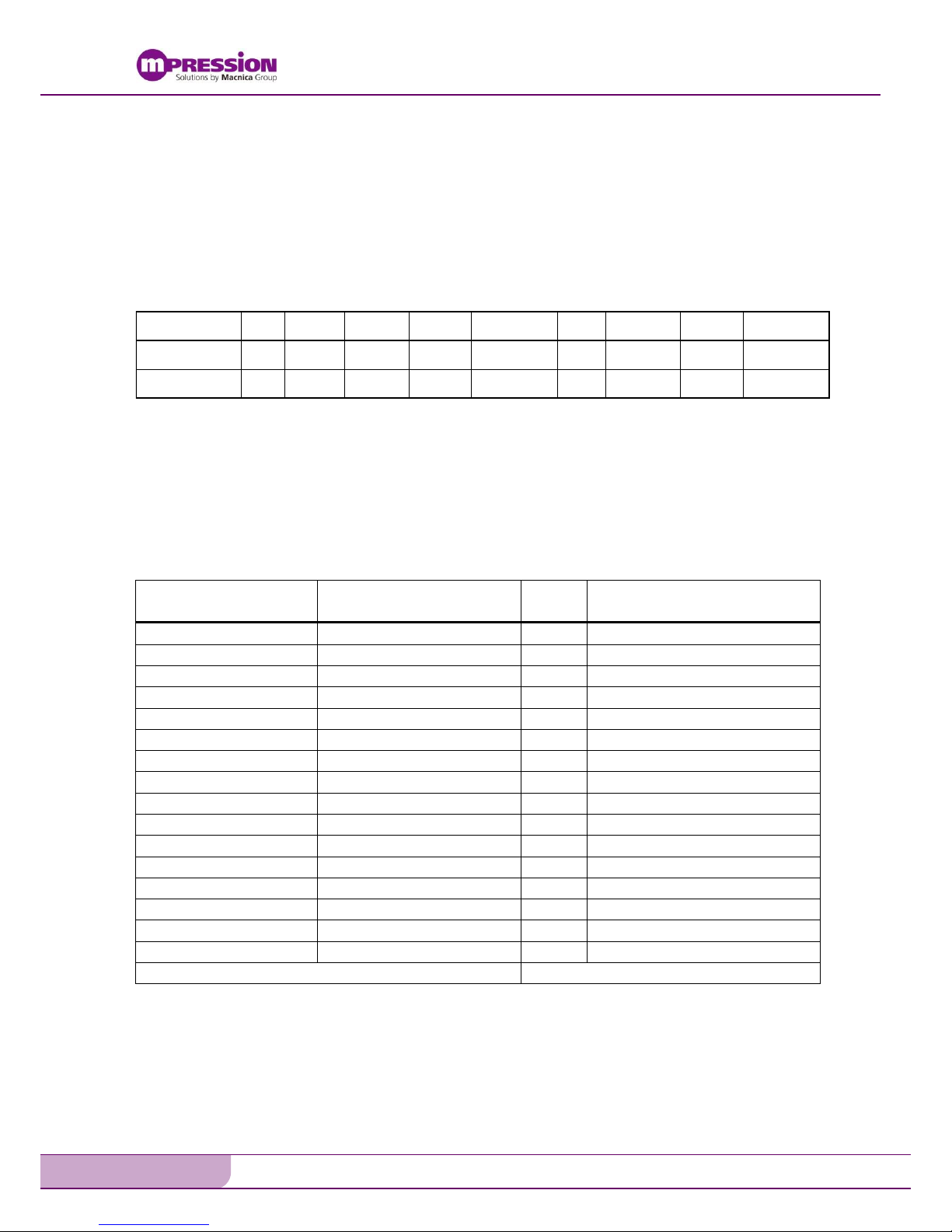

Table 3-2-1. Key components

Supplier

Function Name

Part number

CPU

Altera

SoC with FPGA

5CSXFC6C6U23C8NES(*1)

5CSXFC5C6U23C7N(*2)

Configuration ROM

Altera

Configuration device

EPCQ256SI16N

CPLD

Altera

On-board USB-Blaster®II

EPM570GF100C5N

ROM

Microchip

EEPROM

24LC32A

RAM

Micron

DDR3-SDRAM

MT41J256M16RE

Ethernet

Micrel

Gigabit Ethernet PHY

KSZ9021RN

USB

SMSC(Microchip)

OTG USB PHY

USB3300-EZK

Cypress

USB PHY for USB-Blaster II

CY7C68013A-56BAXC

Real Time Clock

MAXIM

I2C Real time clock

DS1339C-33#

UART

Silicon Labs

USB to UART bridge

CP2103GM

Connector

TE Connectivity

Mictor for HPS

2-5767004-2

Samtec

HSMC

ASP-122953-01

Note: *1) 5CSXFC6C6U23C8NES was mounted in the Helio board Rev1.3 or earlier.

*2) 5CSXFC5C6U23C7N is mounted in the Helio board Rev1.4 or later.

Mpression Helio Board

10 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

3.3 Block Diagram

Figure 3-3-1 shows a block diagram of the Helio board.

Figure 3-3-1. The Helio board Block Diagram

Board Specification

Table 3-3-1. Board specification

PCB Size

Height

Width

100mm

167mm

PCB thickness

1.6mm

Layer number

8 Layers

256MB

DDR3-SDRAM

LVDS/

Single-Ended

Embedded

USB-Blaster II

Type-miniB

USB2.0 Mictor connector

(for HPS)

64MB

QSPI FlashROM

(Not mount)

Gigabit Ethernet

PHY

USB2.0

OTG (On The Go)

32kB

EEPROM

Real Time Clock

UART

(USB to UART bridge)

Push Button

(Re-Config)

Push Button Switch

(Cold, Warm reset)

DIP Switch

(User defined)

DIP Switch

(User defined)

GPIO

(TH)

LEDs

2x16 Char LCD

Header

1GB

DDR3-SDRAM

JTAG_Chain

x 4

x 1

x 4

Ref. cloclk

x32

x 2

SPI

x80

CLKIN x 3

CLK OUT x 3

: FPGA-side peripherals

: HPS-side peripherals

I2C

5CSXFC6C6U23(672pin)

ALTERA

Cyclone V SX SoC

5CSXFC6C6U23C8NES

rev1.3 or earlier

/

5CSXFC5C6U23C7N

rev1.4 or later

Push Button Switch

(User defined)

Configuration ROM

Push Button

(User defined)

x 4

x 3

Fixed OSC

50/100/125MHz x 4

LTC power Monitor

Micro SD Slot

x 4

x 4

x 4

Mpression Helio Board

Reference Manual - Mpression Helio Board 11

© Mpression by Macnica Group

4. The Helio board Components

4.1 Board Overview

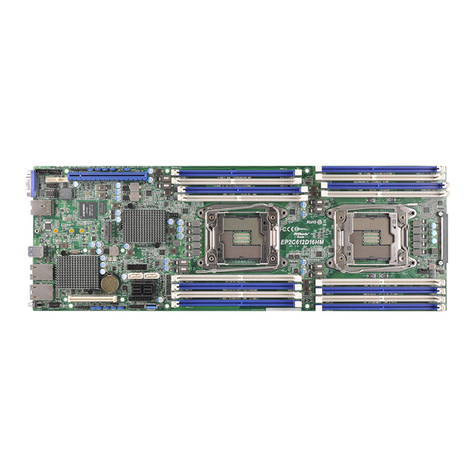

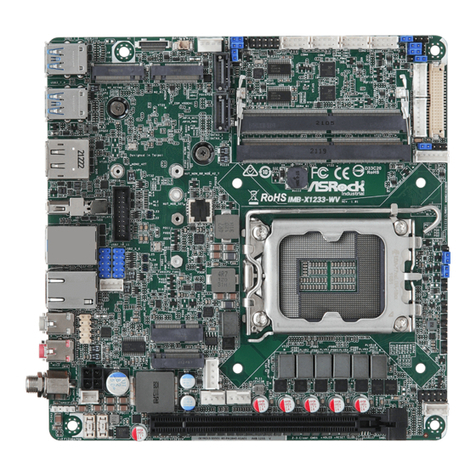

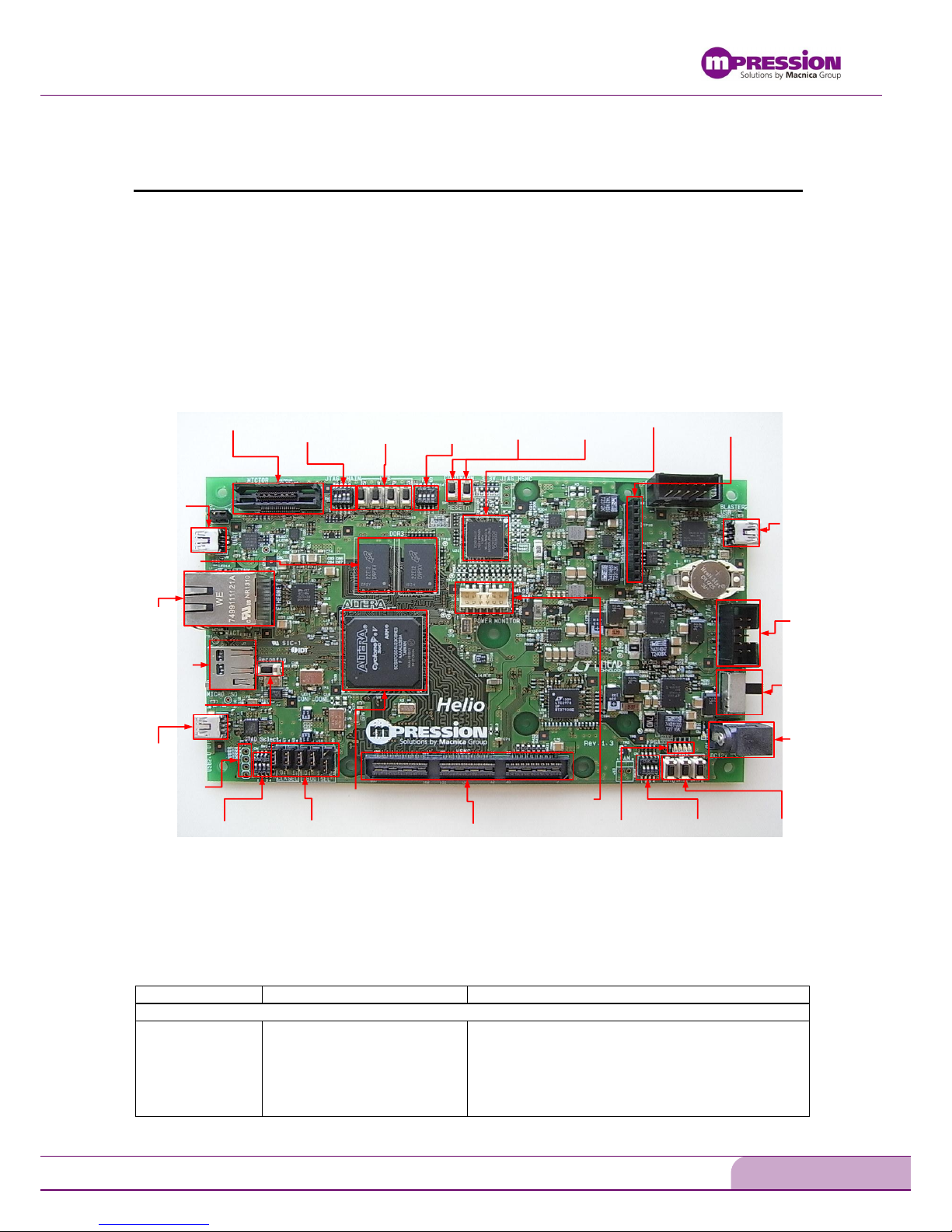

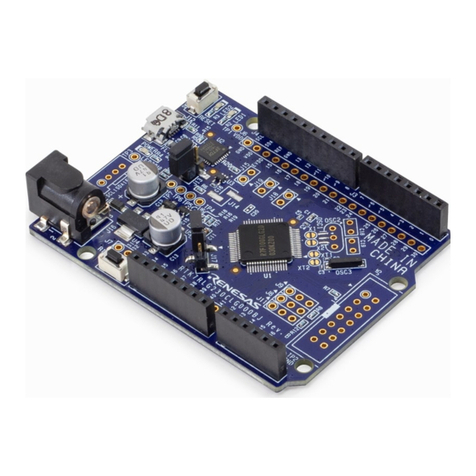

This section provides an overview of the Helio board Figure 4-1-1 shows a top view of the board.

Figure 4-1-1. Board top view

Table 4-1-1 describes the components and lists their corresponding board references.

Table 4-1-1. Board components

Board Reference

Type

Description

Featured Devices

U1

SoC

Cyclone V SoC, 5CSXFC6C6U23C8NES or

5CSXFC5C6U23C7N, 672-pin UBGA.

5CSXFC6C6U23C8NES was mounted in the

Helio board Rev1.3 or earlier.

5CSXFC5C6U23C7N is mounted in the Helio

board Rev1.4 or later.

Warm Reset

Push Button

(SW6)

MAXII CPLD

(U31)

Cold Reset

Push Button

(SW5)

User Defined

Dip Switch

For HPS

(SW14)

User Defined

Push Button

For HPS

(SW7-SW10)

JTAG Master

Select DIP Switch

(SW4)

JTAG 10pin

Header

(J2)

HSMC Port

(J4)

Cyclone V SX SoC (U1)

MICTOR_38P

Port (J1)

UART Port

(J9)

Gigabit

Ethernet

Port (J9)

Micro SD

Socket Port

(J7)

DDR3-SDRAM

(x32bit)

(U16, U17)

Character

LCD Port

(J8)

On Board USB

Blaster II Port

(J11)

USB 2.0 OTG

Port (J6)

User GPIO TH

(GPIO057,

58,59,61)

JTAG Chain Setting

DIP Switch (SW1)

Re-configuration

Push Button

(SW3)

HPS SettingJumper

(J16-J20)

User DIP Switch

For FPGA

(SW15)

User Push Button

For FPGA

(SW11-SW13)

DC Input Jack

(J14)

User LEDs

(LED3-LED6)

Power Monitor

Port (J15)

Power switch

(SW16)

*Power switch

is not mounted

in Rev1.2

Mpression Helio Board

12 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

U31

CPLD

MAX®II CPLD, EPM570GF100C5N, 100-pin FBGA

Configuration, Status, and Setup Elements

J2

JTAG 10pin header

Provides access to the JTAG chain and disables the

embedded USB-Blaster II when using an external

USB-Blaster cable.

SW1

JTAG chain control DIP

Switch

Remove or include devices in the active JTAG chain.

SW4

JTAG master select DIP

Switch

Select master I/F of JTAG chain, and master I/F for

HPS.

J11

USB type-B connector

USB interface for FPGA programming and debugging

thorough the embedded USB-Blaster II JTAG via a

type-B cable.

J16, J17, J18,

J19, J20

HPS setting Jumper switch

Selects for the HPS boot source, and the clock mode.

SW3

Re-configuration push button

FPGA reconfigured by the configuration ROM

(EPCQ) when pushed SW3.

SW5

Cold reset push button

Cold reset: HPS and Ethernet are reset when pushed

SW5.

SW6

Warm reset push button

Warm reset: Only HPS is reset when pushed SW6.

LED1

Configuration done LED

Illuminates when the FPGA is configured.

LED2

Cold reset LED

Illuminates when the HPS is Cold reset.

LED7

UART Transmit LED

Blink when there is UART data to transmit.

LED8

UART Receive LED

Blink when there is data on the UART receive buffer.

LED14

Ethernet LINK LED

Illuminates when the Ethernet linked.

LED15

Ethernet ACT LED

Illuminates when the Ethernet activity.

Clock Circuitry

U6

100-MHz oscillator

100.000-MHz crystal oscillator for the GXB reference

clock.

X1

50-MHz oscillator

50.000-MHz crystal oscillator for general purpose

logic.

X2

25-MHz oscillator

25.000-MHz crystal oscillator for the HPS primary

and secondary clock.

X3

100-MHz oscillator

100.000-MHz crystal oscillator for general purpose

logic.

X4

125-MHz oscillator

125.000-MHz crystal oscillator for general purpose

logic.

General User Input / Output

LED3, LED4,

LED5, LED6

User LEDs

Four user LEDs. Illuminates when driven low.

SW7, SW8, SW9,

SW10

User push button for HPS

Four user push buttons. Connected to the GPIO on

the HPS.

SW11, SW12,

SW13

User push button for FPGA

Three user push buttons. Connected to the IO of the

FPGA.

SW14

User DIP switch for HPS

Four-bit DIP switch. Connected to the GPIO of the

HPS.

SW15

User DIP switch for FPGA

Four-bit DIP switch. Connected to the IO of the

FPGA.

GPIO1, GPIO2,

GPIO3, GPIO4

User GPIO

Four GPIO through holes. Connected to the GPIO of

the HPS.

Memory Devices

U16, U17

DDR3-SDRAM

1GB DDR3-SDRAM (Two 512MB DDR3): Connected

to HPS with a 32-bit data bus.

U21

QSPI-Flash memory

64MB QSPI NOR Flash memory: Connected to HPS.

HPS support serial, Dual, Quad I/O SPI protocols.

Note: QSPI FlashROM was not mounted in the Helio

board.

U7

FPGA configuration ROM

Serial or quad-serial FPGA configuration in devices

that support active serial ASx1 or ASx4 configuration

schemes. 256-Mbit.

U19

EEPROM

32-kbit I2C Serial EEPROM. Connected to HPS

Communication Ports

Mpression Helio Board

Reference Manual - Mpression Helio Board 13

© Mpression by Macnica Group

J1

Mictor connector

The ARM DSTREM or third party debugger is able to

connect to Mictor connector.

J4

HSMC port

Provides 84CMOS or 17LVDS channels per the

HSMC specification.

J5

Gigabit Ethernet port

RJ-45 connector which provides a 10/100/1000

Ethernet connection via a Micrel KSZ9021RL and the

HPS-based Ethernet MAC in RGMII mode.

J6

USB 2.0 OTG port

USB mini-AB connector which provides a USB2.0

Hi-Speed and OTG protocol via a SMSC USB3300

and the HPS-based USB2.0 LINK in ULPI.

J7

Micro SD socket

Micro SD socket which provides a Micro SD via the

HPS-based SD/SDIO/MMC flash controller.

J9

UART port

USB mini-B connector which provides a USB-serial

via a Silicon Labs CP2103 and the HPS-based UART.

J11

On-Board USB-Blaster II port

USB mini-B connector which provides the FPGA

configuration via a Cypress CY7C68013A and an

Altera MAXII CPLD.

Display Interface

J16

Character LCD

Connector that interfaces to a provided 16character

x2 line LCD module along with two standoffs.

Power Supply

J14

DC input jack

Accepts a 12-V DC power supply.

SW16

Power switch

SW16 is the slide switch for power supply ON/OFF.

(However, SW16 is not mounted on the Helio Rev1.2

board. The power supply of the Helio Rev1.2 board is

supplied by connecting an AC adapter.)

Mpression Helio Board

14 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

4.2 Featured Device: Cyclone V SoC

Cyclone V SoC 5CSXFC6C6U23CNES and 5CSXFC5C6U23C7N device in a 672-pin UBGA

package is surface-mounted on the Helio board.

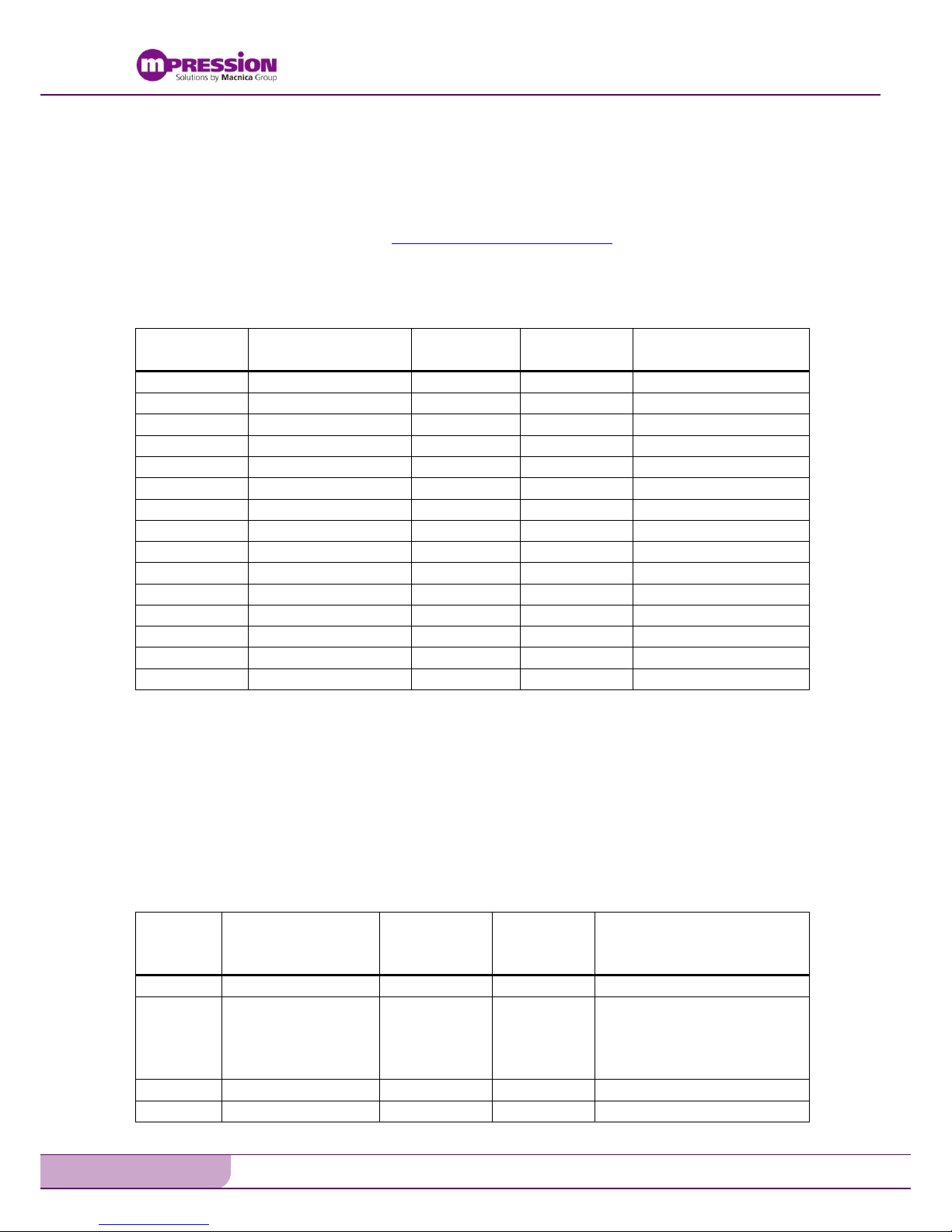

Table 4-2-1 describes the features of the Cyclone V SoC 5CSXFC6C6U23C and 5CSXFC5C6U23C

device.

Table 4-2-1. Cyclone V SoC Features

4.2.1 I/O Resources

The Cyclone V SoC 5CSXFC6C6U23CNES and 5CSXFC5C6U23C7N device has 342 user I/Os and

six transceiver channels. Table 4-2-2 lists the Cyclone V SoC device I/O pin count and usage by

function on this board.

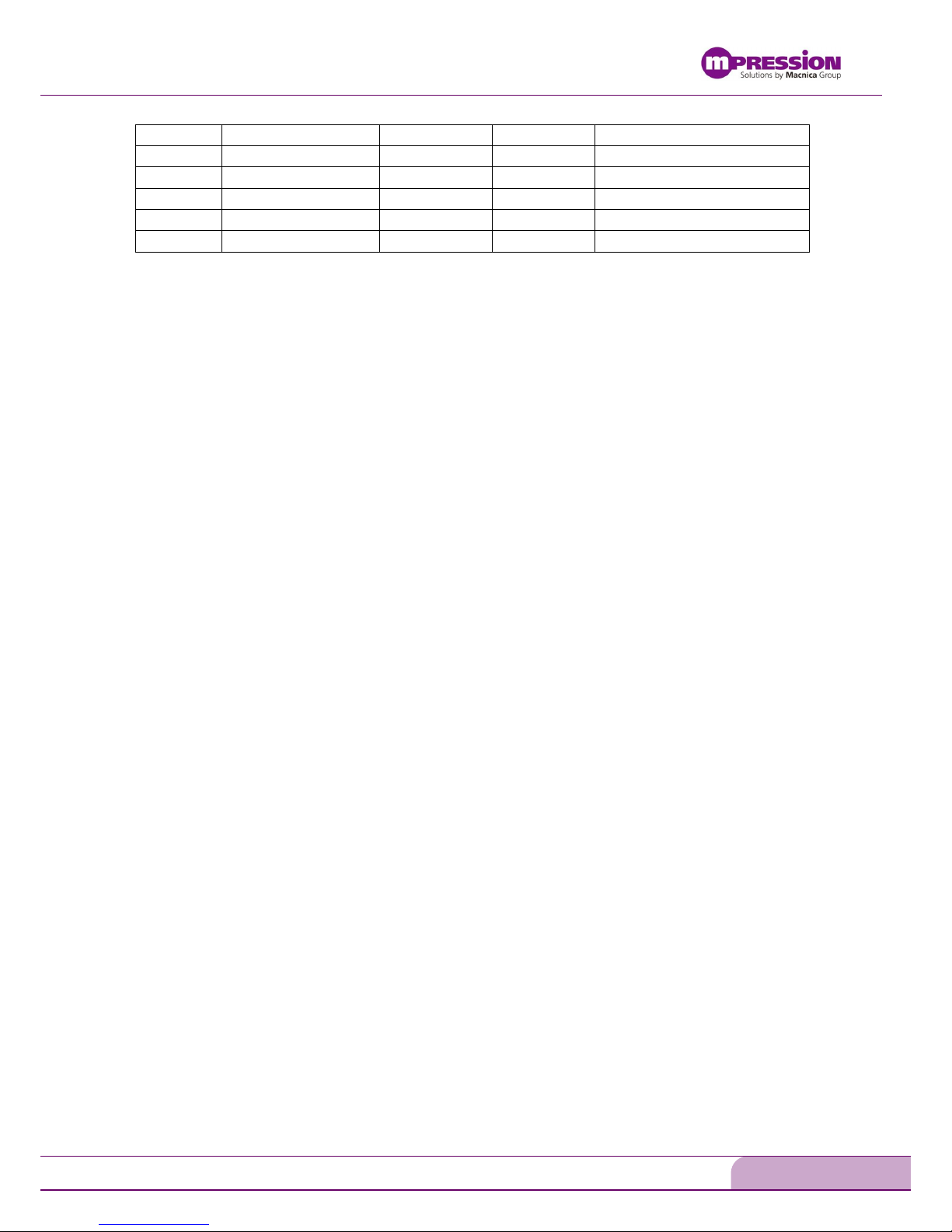

Table 4-2-2. Cyclone V SoC Device I/O Pin Count

Function

I/O Standard

I/O

Count

Special Pins

DDR3-SDRAM

1.5-V SSTL

80

HPS, One differential x4 DQS pin

QSPI FlashROM

3.3-V CMOS

6

HPS

USB2.0 OTG port

3.3-V CMOS

12

HPS

UART

3.3-V CMOS

2

HPS

RTC & EEPROM

3.3-V CMOS

2

HPS (I2C)

Character LCD

3.3-V CMOS

4

HPS

Gigabit Ethernet port

3.3-V CMOS

15

HPS

Push buttons

3.3-V CMOS

2

HPS

Dip switches

3.3-V CMOS

4

HPS

GPIO

3.3-V CMOS

4

HPS

HSMC port

2.5-V CMOS + LVDS

91

17 LVDS, I2C

On-board USB-Blaster II

1.5-V

17

-

Push buttons

2.5-V CMOS

5

User defined, Re-config for FPGA

Dip switches

2.5-V CMOS

4

User defined

LEDs

2.5-V CMOS

4

User defined

Clock or Oscillators

2.5V CMOS + LVDS + PCML

16

Total I/O Used:

268

Device ALMs

Equivalent

LEs

M10K RAM

Blocks

Total RAM

(Kbits)

18-bit x 18-bit

multipliers

PLLs Transceivers

ARM

Cortex-A9

Pakage Type

5CSXFC6C6U23C 41,509 110,000 557 5,570 224

FPGA 6

HPS 3

6 Dual-core 672-pin UBGA

5CSXFC5C6U23C 32,075 85,000 397 3972 174

FPGA 6

HPS 3

6 Dual-core 672-pin UBGA

Mpression Helio Board

Reference Manual - Mpression Helio Board 15

© Mpression by Macnica Group

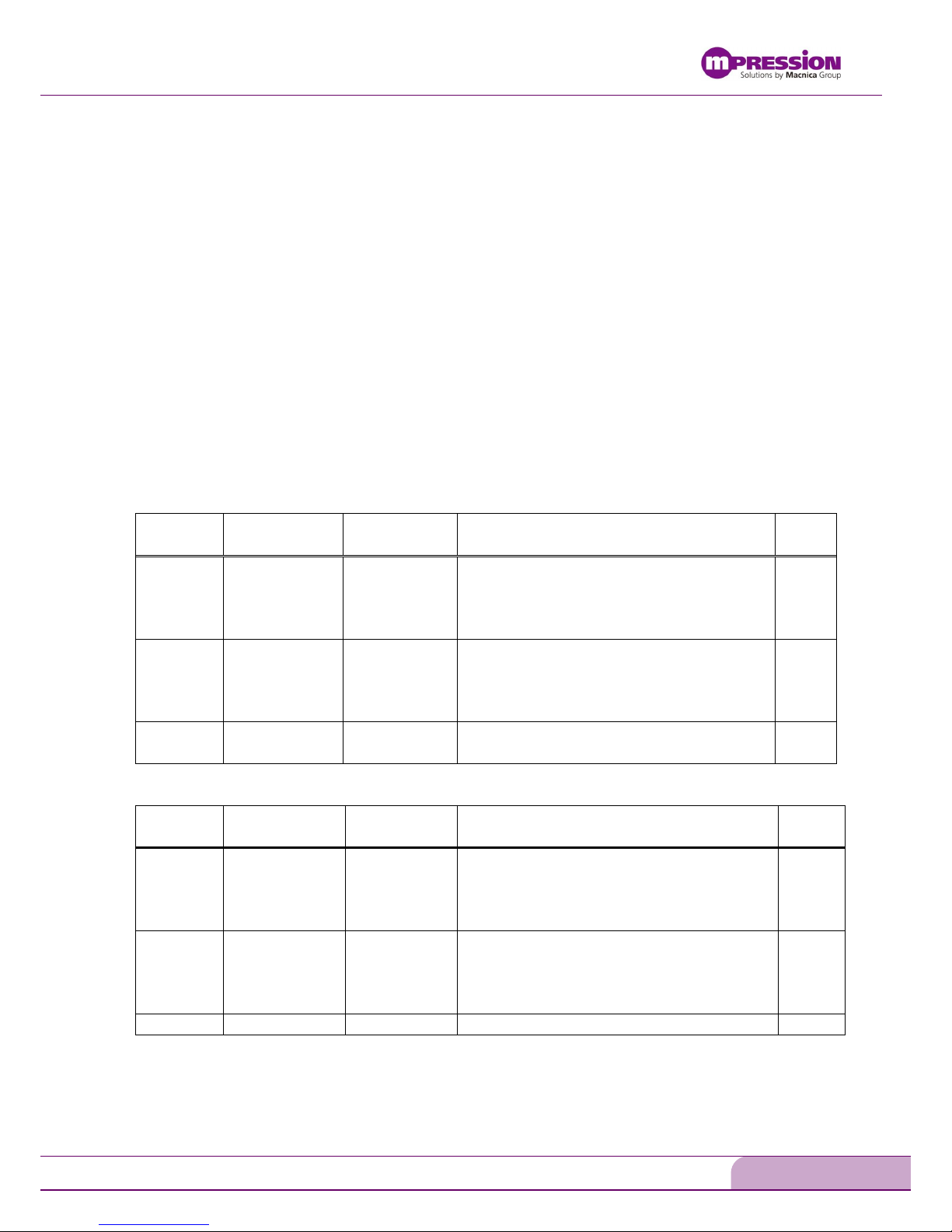

4.3 JTAG Configuration

This section describes configuration methods of FPGA and HPS supported by the Helio board. The

Helio board supports the following three configuration methods:

On-board USB-Blaster II is the default method for configuring the FPGA/HPS using the

Quartus®II Programmer/the ARM DS-5™Altera Edition in JTAG mode with the supplied

USB cable.

Mictor connector is the default method for debugging the HPS using the In-Circuit Emulator

in JTAG mode.

External USB-Blaster for configuring the FPGA/HPS using an external USB-Blaster that connects

to the JTAG chain header (J2).

4.3.1 HPS debugging and FPGA Programming over On-board

USB-Blaster II

This configuration method is implemented using USB-mini type-B connector (J11), a USB 2.0 PHY

device (U33), and an Altera MAX II CPLD EPM570GF100C5N (U31). Connect the USB cable

directly to the USB-Blaster II port of the Helio board.

HPS can be debugged via ARM DS-5 Altera Edition. And FPGA can be programmed via Quartus II

programmer. The On-board USB-Blaster II is normally masters of the JTAG chain. Figure 4-3-1

illustrates the JTAG chain.

Figure 4-3-1. JTAG Chain

The JTAG setting control DIP switch (SW1, SW4) controls the Analog Switch and the Multiplexer

shown in Figure 4-3-1. Refer to 4.5.1 JTAG settings DIP switch if you want to confirm detail

settings for JTAG setting DIP switches.

GPIO

On-Board

USB

-

BlasterII

GPIO

GPIO

GPIO

Cyclone V SoC

FPGA

TCK

TMS

TDI

TDO

JTAG Slave

JTAG Master

TCK

TMS

TDO

GPIO

TDI

HPS_TCK

HPS_TMS

HPS_TDI

HPS_TDO

HPS Side

Bank 7A

HPS_TRST

TCK

Mictor 38P

TMS

TDO

JTAG Master

TDI

TRST

TCK

JTAG 10P

TMS

TDO

JTAG Master

TDI

TRST

Disable

Enable

MUX

TCK

MUX

TMS

TDO

TDI

R

R

Ana log

Switch

TCK

TMS

TDO

TDI

DI P Swi tch

Enable

DI P Swi tch

MICTOR_TRST

MICTOR_TRST

JTAG_TRST

JTAG_TRST

3.3V

3.3V

3.3V

2.5V

VCCIO7A_HPS

3.3V

VCCPD3A

VCCIO3A

FPGA Side

Bank 3A

Analog Switch TS5A23157 supply

voltage = 3.3V

Ana log

Switch

Ana log

Switch

Anal og

Swi tch

3.3V

3.3V

GPIO

Mpression Helio Board

16 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

4.3.2 HPS debugging over Mictor connector for In-Circuit Emulator

Mictor connector (J1) is the connector that has JTAG and Trace data 8-bit bus for HPS debugging

with In-Circuit Emulator of ARM coretex-A9.

JTAG and Trace data 8-bit bus of HPS is connected to Mictor connector when JTAG setting DIP

switch SW1-[2] was OFF. Refer to 4.5.1 JTAG settings DIP switchif you want to confirm detail

settings for JTAG setting DIP switches.

Table 4-3-1 shows the Mictor connector pin assignments.

Table 4-3-1. Mictor Connector Pin Assignments

Board

Reference(J4)

Schematic

Signal Name

I/O Standard

Cyclone V SoC

Pin Number

Description

6

TRACE_CLK_MIC

3.3-V

C21

Trace Clock

9

MICTOR_RSTn

3.3-V

A23

HPS Reset

11

JTAG_MICTOR_TDI

3.3-V

D22

JTAG Data Input

15

JTAG_MICTOR_TCK

3.3-V

H22

JTAG Clock

16

TRACE_DATA7

3.3-V

C18

Trace Data Bit 7

17

JTAG_MICTOR_TMS

3.3-V

A29

JTAG Mode Select

18

TRACE_DATA6

3.3-V

A19

Trace Data Bit 6

19

JTAG_MICTOR_TDO

3.3-V

B23

JTAG Data Output

20

TRACE_DATA5

3.3-V

J18

Trace Data Bit 5

21

MICTOR_TRST

3.3-V

C22

JTAG Reset

22

TRACE_DATA4

3.3-V

A20

Trace Data Bit 4

24

TRACE_DATA3

3.3-V

K18

Trace Data Bit 3

26

TRACE_DATA2

3.3-V

A21

Trace Data Bit 2

28

TRACE_DATA1

3.3-V

B21

Trace Data Bit 1

38

TRACE_DATA0

3.3-V

A22

Trace Data Bit 0

4.3.3 FPGA Programming over External USB-Blaster

The JTAG header (J2) provides another method for configuring the FPGA using an external

USB-Blaster device with the Quartus II Programmer running on a PC. To prevent contention

between the JTAG masters, the On-board USB-Blaster II is automatically disabled when you

connect an external USB-Blaster to the JTAG chain through the JTAG header (J2). Table 4-3-2 lists

the JTAG header pin assignment.

Table 4-3-2. JTAG header Pin Assignments

Board

Reference

(J2)

Schematic

Signal Name

I/O Standard

Cyclone V

SoC

Pin Number

Description

1

JTAG_TCK

3.3-V

―

JTAG Clock

2

USB_DISABLEn

3.3-V

―

On-board USB-Blaster II disable

when JTAG header is used,

the On-board USB-Blaster II

JTAG interface cannot be used.

3

JTAG_BLASTER_TDI

3.3-V

―

JTAG Data from device

4

3.3V

―

―

3.3V Power

Mpression Helio Board

Reference Manual - Mpression Helio Board 17

© Mpression by Macnica Group

5

JTAG_TMS

3.3-V

―

JTAG Mode Select

6

MICTOR_RSTn

3.3-V

―

Mictor Reset Signal Input

7

8

JTAG_TRST

3.3-V

―

JTAG Reset

9

JTAG_BLASTER_TDO

3.3-V

―

JTAG Data to device

10

GND

―

―

Ground

Mpression Helio Board

18 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

4.4 Status Elements

The Helio board includes status LEDs. This section describes the status elements.

Table 4-4-1 lists the LED board references, name, and functional descriptions.

Table 4-4-1. Board-Specific LEDs

Board

Reference

Schematic

Signal Name

I/O Standard

Description

LED1

CONF_DONE(Inverted)

3.3-V

Green LED. Illuminates when FPGA

is successfully configured.

LED2

COLD_RESETn

3.3-V

Red LED.

Illuminates when cold_reset is asserted.

LED13

5.0V (Power)

5.0-V

Green LED.

Illuminates when 5.0V power is active.

Mpression Helio Board

Reference Manual - Mpression Helio Board 19

© Mpression by Macnica Group

4.5 Setup Elements

The Helio board includes some of setup elements. This section describes the following setup

elements:

JTAG settings DIP switch

HPS operation mode setting Jumper

HPS reset push button

Program configuration push button

MSEL pins settings

4.5.1 JTAG settings DIP switch

The JTAG setting control DIP switch (SW1, SW4) remove or include devices in the active JTAG

chain and select JTAG master interface. Table 4-5-1, Table 4-5-2 lists the switch controls and its

descriptions.

Table 4-5-1. JTAG Setting Control DIP Switch (SW1)

Board

Reference

Schematic

Signal Name

I/O Standard

Description

Default

SW1-1

JTAG_SEL

3.3-V

JTAG master interface select:

ON : Select On-board USB-Blaster II

or JTAG 10pin Header

OFF : Select MICTOR connector

ON

SW1-2

JTAG_HPS_SEL

3.3-V

Cyclone V SoC HPS JTAG Master Select:

ON : Select On-board USB-Blaster II

or JTAG 10pin Header

OFF : Select MICTOR connector

ON

SW1-[3:4]

-

-

This switch has to set ON when normal

operation.

ON

Table 4-5-2. JTAG Setting Control DIP Switch (SW4)

Board

Reference

Schematic

Signal Name

I/O Standard

Description

Default

SW4-1

HPS_JTAG_EN

3.3-V

Remove or include HPS side in the active JTAG

chain:

ON : Bypass Cyclone V SoC HPS Side

OFF : Cyclone V SoC HPS Side in-chain

OFF

SW4-2

FPGA_JTAG_EN

3.3-V

Remove or include FPGA side in the active JTAG

chain:

ON : Bypass Cyclone V SoC FPGA Side

OFF : Cyclone V SoC FPGA Side in-chain

OFF

SW4-[3:4]

-

-

This switch has to set ON when normal operation.

ON

Mpression Helio Board

20 Reference Manual - Mpression Helio Board

© Mpression by Macnica Group

4.5.2 HPS operation mode settings Jumper

The HPS operation mode setting Jumpers are Jumper for the Cyclone V SoC HPS side BSEL[2:0]

and CSEL[1:0]. Table 4-5-3 shows the HPS operation mode setting Jumper.

Table 4-5-3. HPS operation mode setting Jumper

Board

Reference

Schematic

Signal Name

I/O Standard

Description

J16

SPI_CSn

(BOOTSEL0)

3.3-V

boot select BSEL0:

Jumper setting

BSEL0

Default

1-2 short

High(1)

1-2 short

2-3 short

Low(0)

J18

QSPI_SS0

(BOOTSEL1)

3.3-V

boot select BSEL1:

Jumper setting

BSEL1

Default

1-2 short

High(1)

2-3 short

2-3 short

Low(0)

J20

BOOTSEL2

3.3-V

boot select BSEL2:

Jumper setting

BSEL2

Default

1-2 short

High(1)

1-2 short

2-3 short

Low(0)

J17

UART_TX

(CLKSEL0)

3.3-V

clock select CSEL0:

Jumper setting

CSEL0

Default

1-2 short

High(1)

2-3 short

2-3 short

Low(0)

J19

CLKSEL1

3.3-V

clock select CSEL1:

Jumper setting

CSEL1

Default

1-2 short

High(1)

2-3 short

2-3 short

Low(0)

For more information on the BSEL and CSEL of HPS, refer to the following document:

Booting and Configuration of Cyclone V SoC HPS, refer to the cv_5400A.

4.5.3 HPS reset push button

The HPS reset push button, COLD_RESETn (SW5) and WARM_RESETn (SW6), are input to the

Cyclone V SoC HPS_PORn and HPS_nRST pin. Table4-5-4 lists the button controls and its

descriptions.

Table of contents

Popular Motherboard manuals by other brands

VIA Technologies

VIA Technologies EPIA-N701 user manual

Renesas

Renesas RL78 Series user manual

Connect One

Connect One II-EVB-363MW user manual

Texas Instruments

Texas Instruments Stellaris EK-LM3S9B92 user manual

American Megatrends

American Megatrends Baby Screamer LC user guide

Biostar

Biostar U8788 Bios setup manual