1. Wipe the interior of the collector chamber with a soft cloth or paper towel to remove any accumulated

moisture.

2. Check the collector chamber drain hose to ensure that the hose is free of moisture and that the drain plug is

securely installed. The freeze dryer will not start if moisture is detected.

3. Using a soft, lint-free cloth or paper towel, wipe the collector chamber lid gasket to remove any dirt and

contaminants that could cause a vacuum leak. Vacuum grease is not required on the lid gasket to obtain a proper

vacuum seal.

4. Remove the accessory drying chamber or manifold from the connection port and using a soft, lint-free cloth

or paper towel, wipe the port gasket and sealing surfaces of the drying chamber/manifold to remove any dirt and

contaminants that could cause a vacuum leak. Reinstall the drying chamber or manifold on the port. Vacuum

grease is not required on the port gasket to obtain a proper vacuum seal.

5. Check that each sample valve is closed or in the “upwards” position.

MAINTAINING YOUR FREEZE DRYER

Under normal operation, the Freeze Dryer requires little maintenance. The following maintenance schedule is

recommended:

As needed:

1. Clean up all spills; remove liquids from the chamber.

2. Clean lid and gasket using soft cloth, sponge or chamois and a mild, non-abrasive soap or detergent.

3. Check oil level of the vacuum pump. It should be over the middle line of oil mirror, If the oil level is lower,

add oil to proper level.

4. If oil shows cloudiness, particles or discoloration, drain the pump and replace with fresh oil.

5. Utilization of acids requires immediate cleaning and neutralization after a run or physical damage to the

collector chamber and collector coil will result.

6. Check the collection chamber for condensed or frozen solvents and dispose of appropriately. Completely

empty the collector chamber before the next run or before starting the vacuum pump.

7. If chamber or manifold valves leak or stems become difficult to turn, pull the stem out of the rubber valve

body and apply a thin coat of vacuum grease to the stem. Reinsert the stem into the valve body.

CHAPTER 5

TROUBLESHOOTING

Refer to the following if your Freeze Dryer fails to operate properly. If the suggested corrective actions do not

solve your problem, contact us for additional assistance.

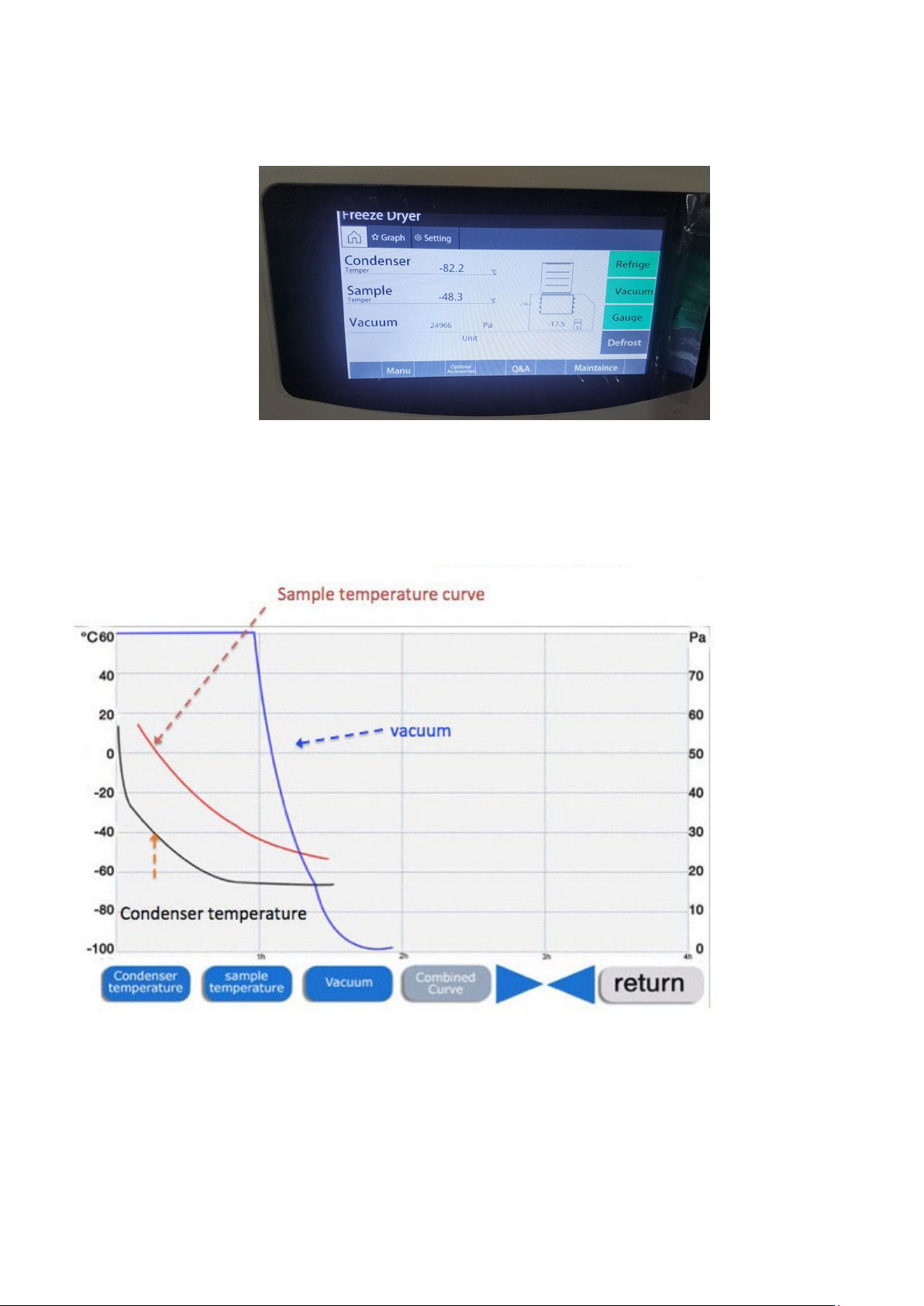

Freeze Dry Systems should reach a vacuum of 999Pa or lower within 10 minutes, and should achieve an ultimate

vacuum of 15Pa or lower within 30 minutes when the refrigeration is operating. If the Freeze Dryer does not

obtain a satisfactory vacuum, perform the following maintenance tests.

I. Vacuum Pump

First make sure that the vacuum pump operates. If it fails to operate, check the electrical connections of the

Freeze Dryer to the power source and then check the electrical connection of the vacuum pump to the Freeze

Dryer. If the vacuum pump has a power switch, make sure that it is turned on. If the vacuum is not adequate

when the vacuum pump is operating, proceed with the following steps:

1. Check the oil and ensure it is clear and clean. If the oil looks cloudy or has any particulates, replace the

pump oil. Sometimes it may be necessary to flush the pump with

clean oil several times. To flush the pump, run the pump 5 to 10 minutes to allow the oil to warm up. Drain the