MTD 315-800-000 User manual

Other MTD Snow Blower manuals

MTD

MTD Yard Machines E602E User manual

MTD

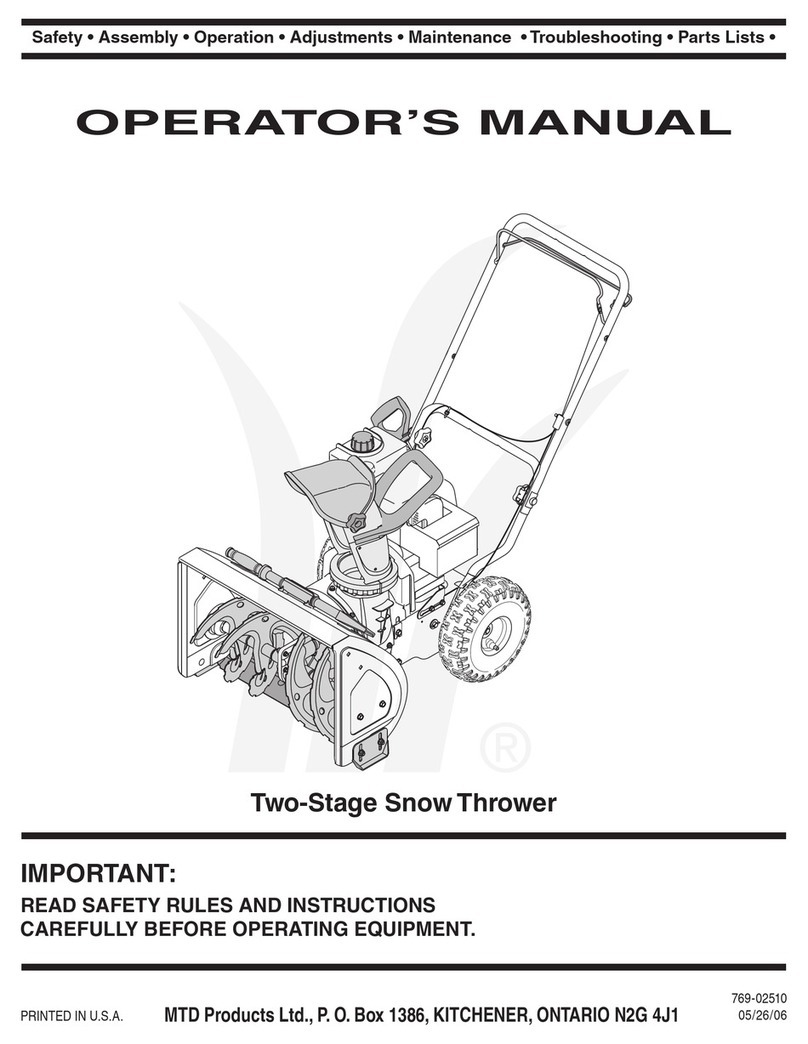

MTD H660G User manual

MTD

MTD 31AE6FHG705 User manual

MTD

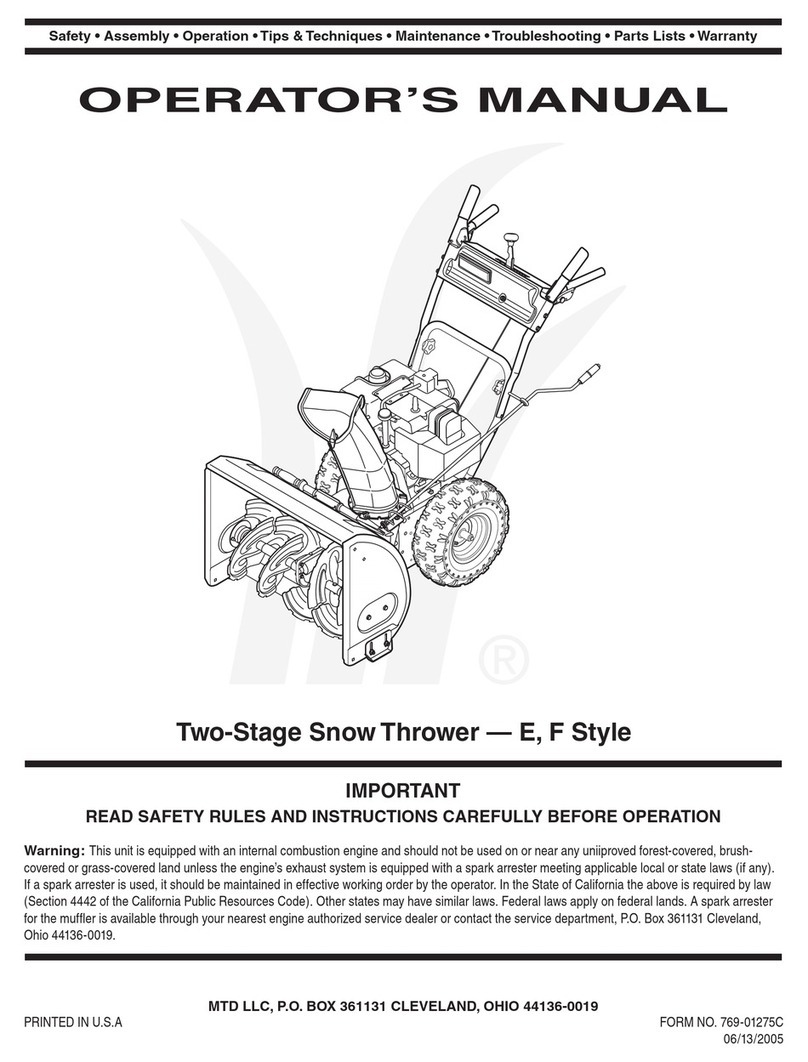

MTD 769-01275C User manual

MTD

MTD 140 Series User manual

MTD

MTD 316-180-000 User manual

MTD

MTD 31AS6BN2711 User manual

MTD

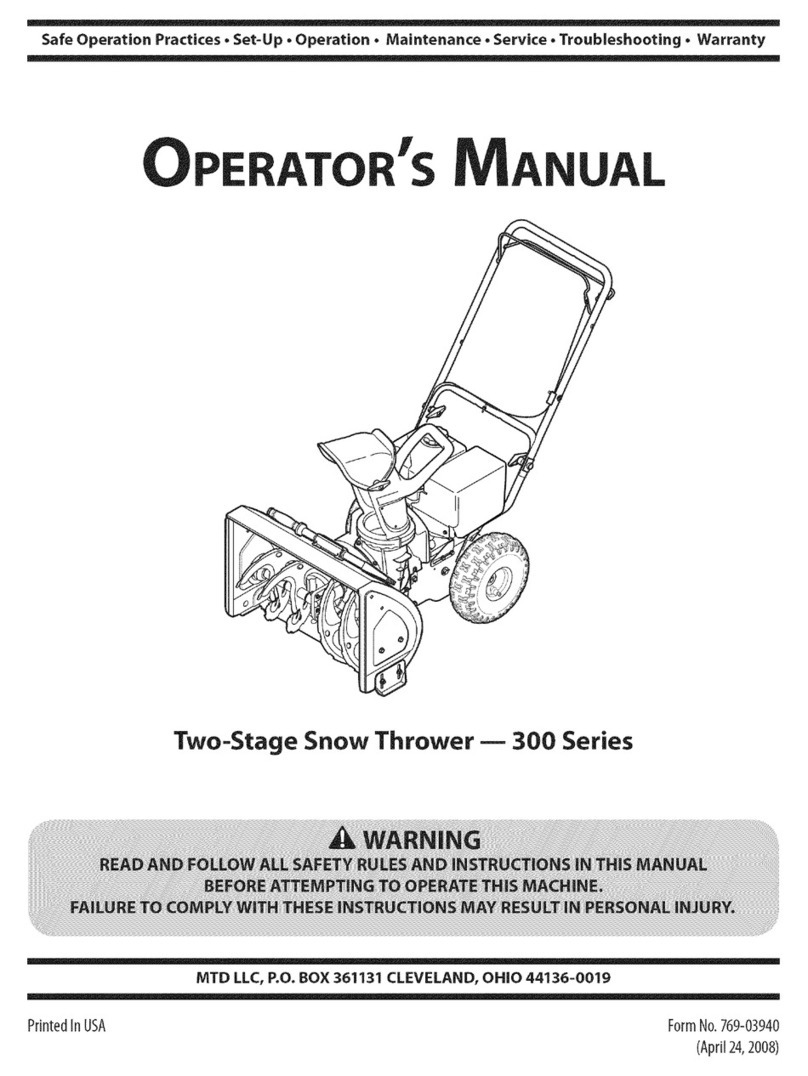

MTD 300 Series User manual

MTD

MTD 31AE6LLG722 User manual

MTD

MTD Two-Stage Snow Thrower 300series User manual