4Section 2 — important Safe operation practiceS

Safe Handling of Gasoline

To avoid personal injury or property damage use extreme care

in handling gasoline. Gasoline is extremely flammable and the

vapors are explosive. Serious personal injury can occur when

gasoline is spilled on yourself or your clothes which can ignite.

Wash your skin and change clothes immediately.

a. Use only an approved gasoline container.

b. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

c. Never fuel machine indoors.

d. Never remove gas cap or add fuel while the engine is

hot or running.

e. Allow engine to cool at least two minutes before

refueling.

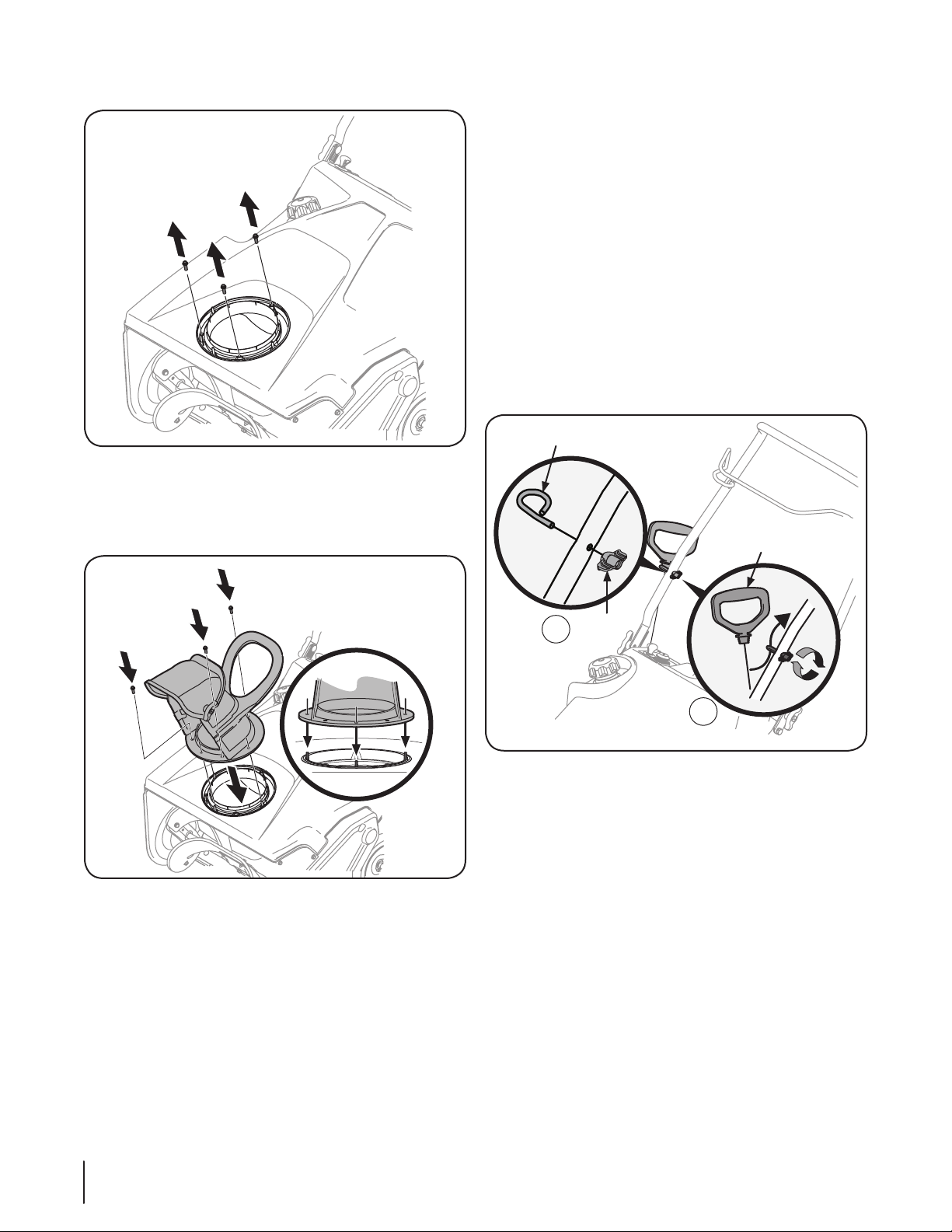

f. Never over fill fuel tank. Fill tank to no more than ½

inch below bottom of filler neck to provide space for

fuel expansion.

g. Replace gasoline cap and tighten securely.

h. If gasoline is spilled, wipe it off the engine and

equipment. Move machine to another area. Wait 5

minutes before starting the engine.

i. Never store the machine or fuel container inside

where there is an open flame, spark or pilot light

(e.g. furnace, water heater, space heater, clothes

dryer etc.).

j. Allow machine to cool at least 5 minutes before

storing.

k. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

l. If possible, remove gas-powered equipment from

the truck or trailer and refuel it on the ground. If this

is not possible, then refuel such equipment on a

trailer with a portable container, rather than from a

gasoline dispenser nozzle.

m. Keep the nozzle in contact with the rim of the fuel

tank or container opening at all times until fueling is

complete. Do not use a nozzle lock-open device.

Operation

1. Do not put hands or feet near rotating parts, in the auger/

impeller housing or chute assembly. Contact with the

rotating parts can amputate hands and feet.

2. The auger/impeller control lever is a safety device. Never

bypass its operation. Doing so makes the machine unsafe

and may cause personal injury.

3. The control levers must operate easily in both directions

and automatically return to the disengaged position when

released.

4. Never operate with a missing or damaged chute assembly.

Keep all safety devices in place and working.

5. Never run an engine indoors or in a poorly ventilated area.

Engine exhaust contains carbon monoxide, an odorless

and deadly gas.

6. Do not operate machine while under the influence of

alcohol or drugs.

7. Muffler and engine become hot and can cause a burn. Do

not touch. Keep children away.

8. Exercise extreme caution when operating on or crossing

gravel surfaces. Stay alert for hidden hazards or traffic.

9. Exercise caution when changing direction and while

operating on slopes.

10. Plan your snow-throwing pattern to avoid discharge

towards windows, walls, cars etc. Thus, avoiding possible

property damage or personal injury caused by a ricochet.

11. Never direct discharge at children, bystanders and pets or

allow anyone in front of the machine.

12. Do not overload machine capacity by attempting to clear

snow at too fast of a rate.

13. Never operate this machine without good visibility or light.

Always be sure of your footing and keep a firm hold on the

handles. Walk, never run.

14. Disengage power to the auger/impeller when transporting

or not in use.

15. Never operate machine at high transport speeds on

slippery surfaces. Look down and behind and use care

when backing up.

16. If the machine should start to vibrate abnormally, stop

the engine, disconnect the spark plug wire and ground it

against the engine. Inspect thoroughly for damage. Repair

any damage before starting and operating.

17. Disengage all control levers and stop engine before you

leave the operating position (behind the handles). Wait

until the auger/impeller comes to a complete stop before

unclogging the chute assembly, making any adjustments,

or inspections.

18. Never put your hand in the discharge or collector openings.

Do not unclog chute assembly while engine is running.

Shut off engine and remain behind handles until all moving

parts have stopped before unclogging.

19. Use only attachments and accessories approved by the

manufacturer (e.g. wheel weights, tire chains, cabs etc.).

20. When starting engine, pull cord slowly until resistance

is felt, then pull rapidly. Rapid retraction of starter cord

(kickback) will pull hand and arm toward engine faster than

you can let go. Broken bones, fractures, bruises or sprains

could result.

21. If situations occur which are not covered in this manual, use

care and good judgment. Contact Customer Support for

assistance and the name of your nearest servicing dealer.