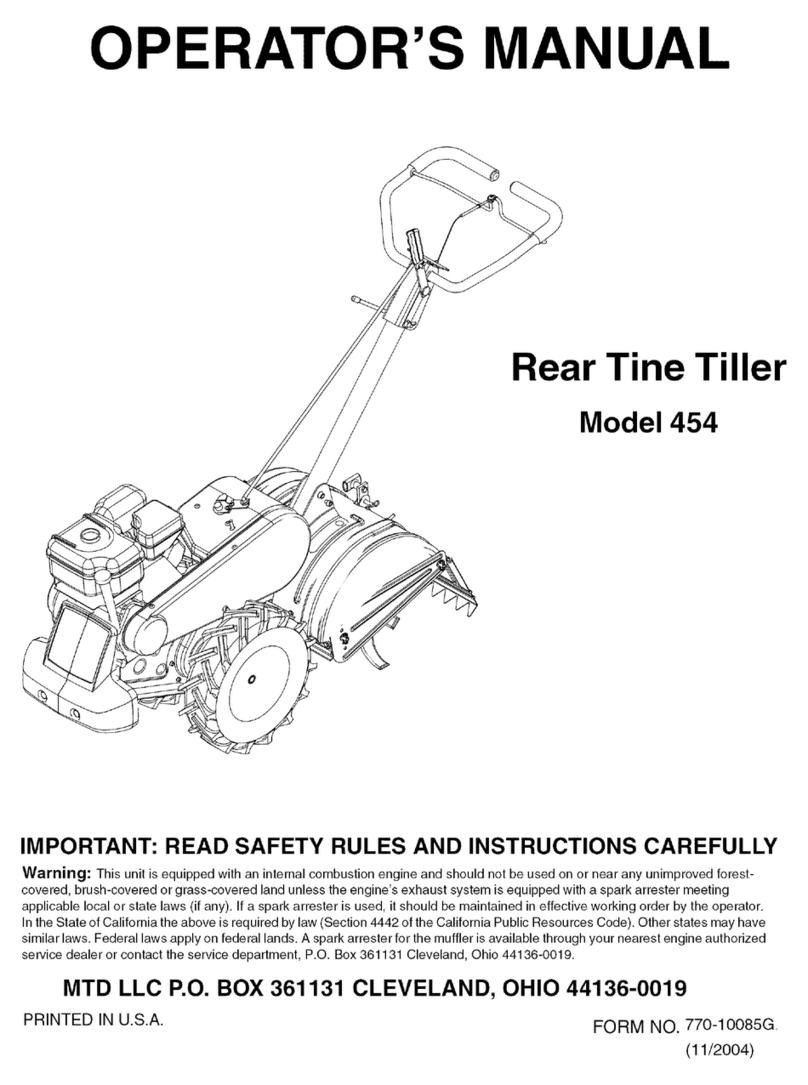

Operat on

WARNING

This symbol points

out important safety

instructionswhich, if

notfollowed,could

endangerthe personal

safetyand/or property

of yourself and others.

Readand follow all

instructionsinthis man-

ualbeforeattempting to

operatethis machine.

Failureto complywith

these instructions

may result in personal

injury.Whenyousee

i this symbol, HEED ITS

WARNING!

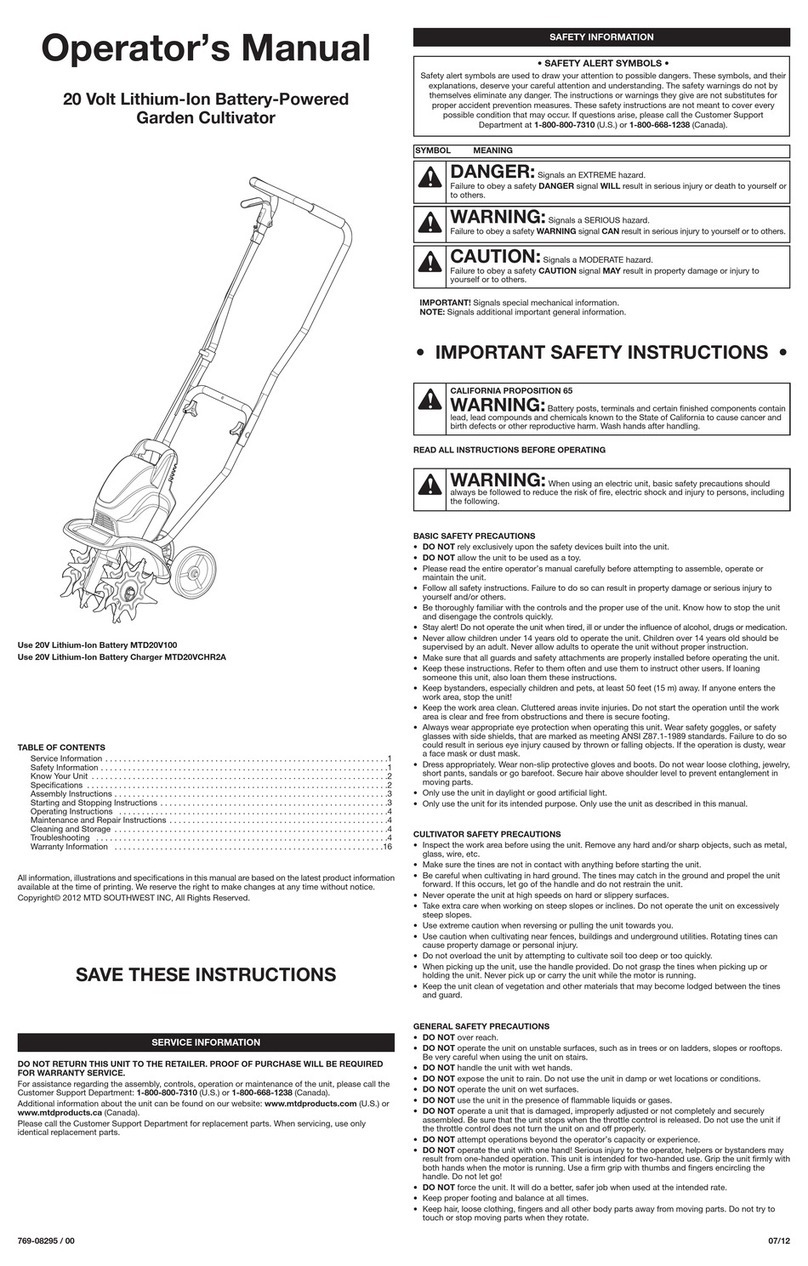

WARNING: EngineExhaust,some of itsconstituents,andcertain vehiclecompo-

nentscontain or emit chemicals knownto Stateof Californiato cause cancerand

birth defectsor other reproductiveharm.

DANGER: Thismachinewas builtto beoperatedaccordingto the rulesfor safe operationin this

manual.As with anytype of powerequipment,carelessnessor erroronthe part ofthe operatorcan

result in seriousinjury.This machine is capableof amputatinghands andfeet andthrowing objects.

Failureto observethe followingsafety instructionscould resultin serious injury ordeath.

Training

1. Read,understand,andfollowall instructionsonthemachine

and in the manual(s)beforeattemptingto assembleand

operate.Keepthismanualina safeplaceforfuture and

regularreferenceandfor orderingreplacementparts.

2. Befamiliarwithall controlsandtheirproperoperation.Know

howtostopthe machine.

3. Neverallowchildrenunder14yearsoldto operatethis

machine.Children14yearsoldand overshouldreadand

understandthe operationinstructionsandsafetyrules in

this manualandshouldbetrainedand supervisedbya

parent.

4. Neverallowadultsto operatethismachinewithoutproper

instruction.

5. Keepbystanders,helpers,petsandchildrenatleast75feet

fromthe machinewhile it isin operation.Stop machineif

anyoneentersthe area.

Preparation

1. Thoroughlyinspectthe areawheretheequipmentisto be

used.Removeallstones,sticks,wire,andotherforeign

objectswhichcouldbetrippedoverandcausepersonal

injury.

2 Wearsturdy,rough-soledworkshoesand closefitting

slacksand shirt.Loosefittingclothesor jewelrycan be

caughtin movableparts.Neveroperatethismachinein bare

feet or sandals.

3. Disengageclutchleversand shift(ifprovided)intoneutral

("N")beforestartingthe engine.

4. Neverleavethis machineunattendedwiththe engine

running.

5. Neverattemptto makeanyadjustmentswhile engineis

running,exceptwherespecificallyrecommendedinthe

operator'smanual.

6. Toavoid personalinjury orpropertydamageuseextreme

carein handlinggasoline.Gasolineis extremelyflammable

andthevaporsareexplosive.Seriouspersonalinjurycan

occurwhengasolineisspilledonyourselforyourclothes

which canignite.Washyourskin andchangeclothes

immediately.

7. Useonlyanapprovedgasolinecontainer.

8. Extinguishallcigarettes,cigars,pipesand othersourcesof

ignition.

9. Neverfuel machineindoors.

10.Neverremovegascapor addfuel whiletheengineishot or

running.

11.Allowenginetocoolat leasttwo minutesbeforerefueling

12.Neveroverfillfuel tank. Filltankto nomorethanY2inch

belowbottomoffillerneckto providespacefor fuel

expansion.

13. Replacegasolinecapandtightensecurely.

14. Ifgasolineisspilled,wipeit offthe engineand

equipment.Movemachinetoanotherarea.Wait5

minutesbeforestartingthe engine.

15. Neverstorethe machineorfuelcontainerinsidenearan

openflame,sparkor pilotlight(e.g.furnace,wateror

spaceheater,clothesdryer,etc.).

16. Allowmachineto cool5minutesbeforestoring.

Operation

1. Do notput handsor feetnear rotatingparts.Contactwith

the rotatingpartscanamputatehandsandfeet.

2. Do notoperatemachinewhileunderthe influenceofalcohol

or drugs.

3. Neveroperatethismachinewithoutgoodvisibility or light.

Alwaysbesureof yourfootingand keepafirm hold onthe

handles.

4. Keepbystanders,helpers,pets,and childrenat least75feet

fromthe machinewhile itis inoperation.Stopthe machineif

anyoneentersthe area.

5. Becarefulwhentillingin hardground.Thetines maycatch

in the groundand propelthe tillerforward.Ifthis occurs,let

goof the handlebarsanddo notrestrainthe machine.

6. Exerciseextremecautionwhenoperatingonor crossing

gravelsurfaces.Stayalertfor hiddenhazardsor traffic.

7. Neveroperatethe machineat hightransportspeedsonhard

or slipperysurfaces.

8. Exercisecautionto avoidslippingorfalling.

9. Lookdownand behindand usecare whenin reverseor

pullingmachinetowardsyou.

10.Startthe engineaccordingtothe instructionsfoundin this

manualandkeepfeet wellawayfromthetinesat alltimes.

11.Afterstrikinga foreignobject,stoptheengine,disconnect

the sparkplugwireand groundagainstthe engine

Thoroughlyinspectthe machineforanydamage.Repairthe

damagebeforestarting andoperating.

12.Disengageall clutchlevers(iffitted)and stopenginebefore

youleavetheoperatingposition(behindthe handles).Wait

untilthetinescometoacompletestopbeforeunclogging

thetines, makinganyadjustments,orinspections.

13.Neverrun anengineindoorsor inapoorlyventilatedarea.

Engineexhaustcontainscarbonmonoxide,an odorlessand

deadlygas.

14.Mufflerand enginebecomehotandcancausea burn.Do

nottouch.

15.Use cautionwhentilling nearfences,buildingsand

undergroundutilities.Rotatingtinescancause property

damageor personalinjury.

4