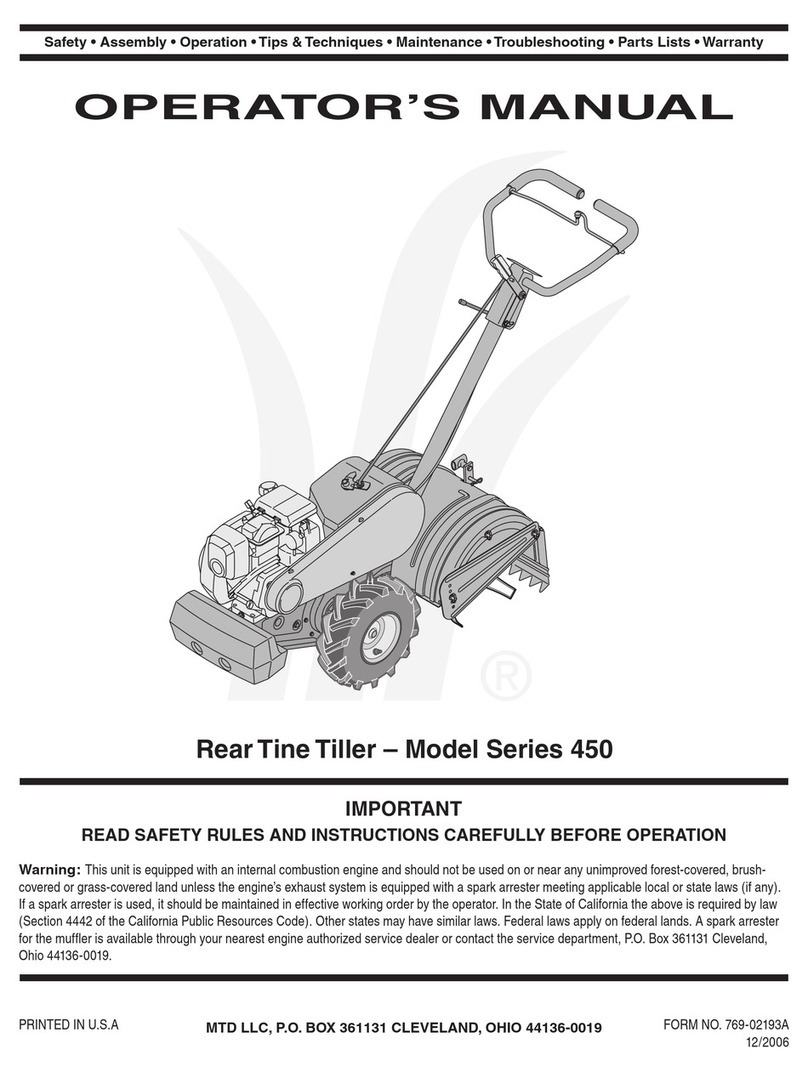

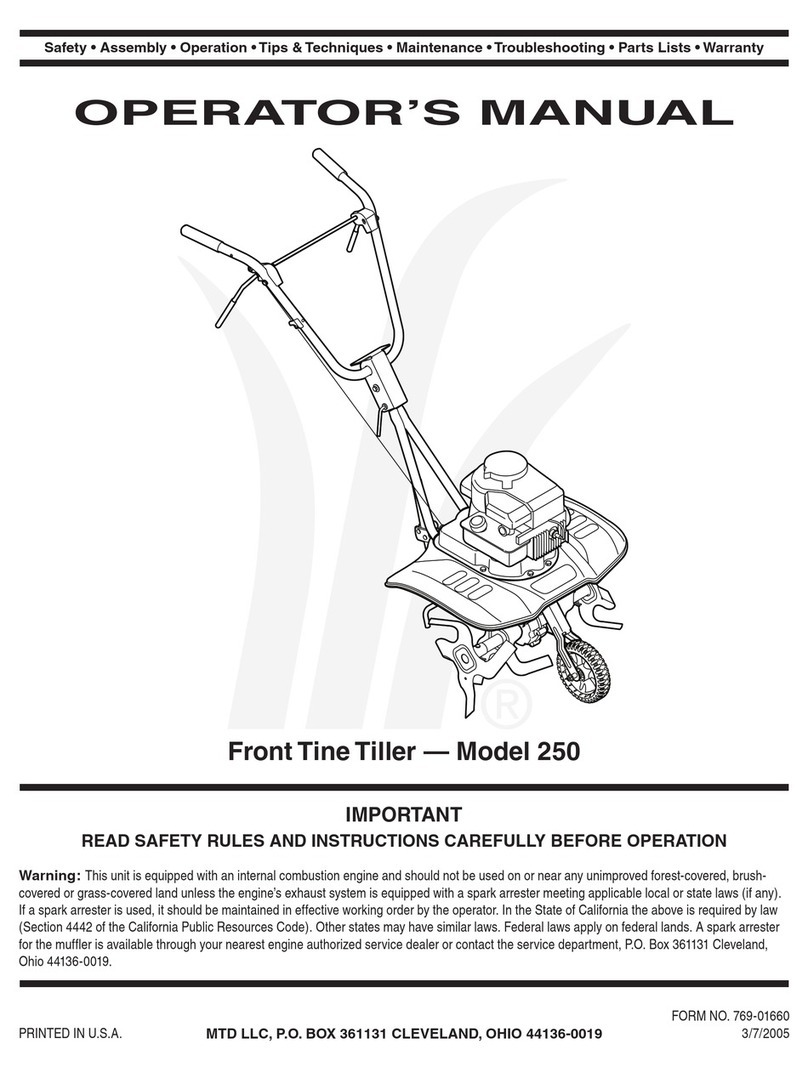

MTD 214-381-000 User manual

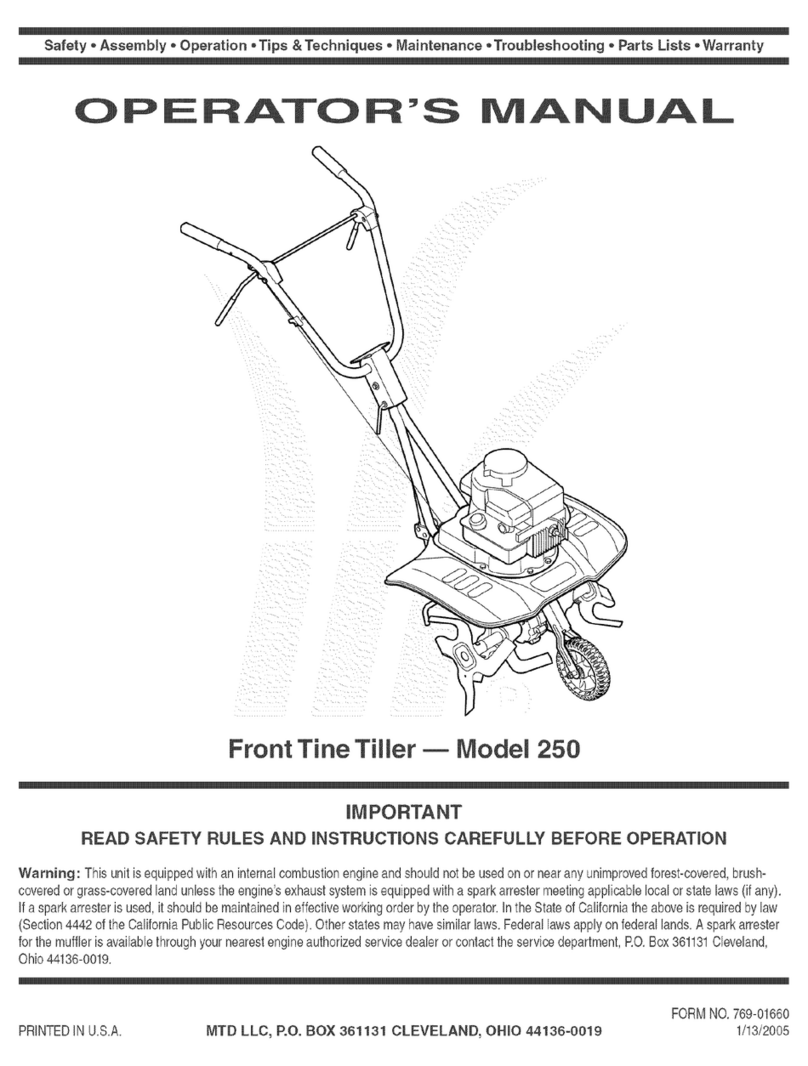

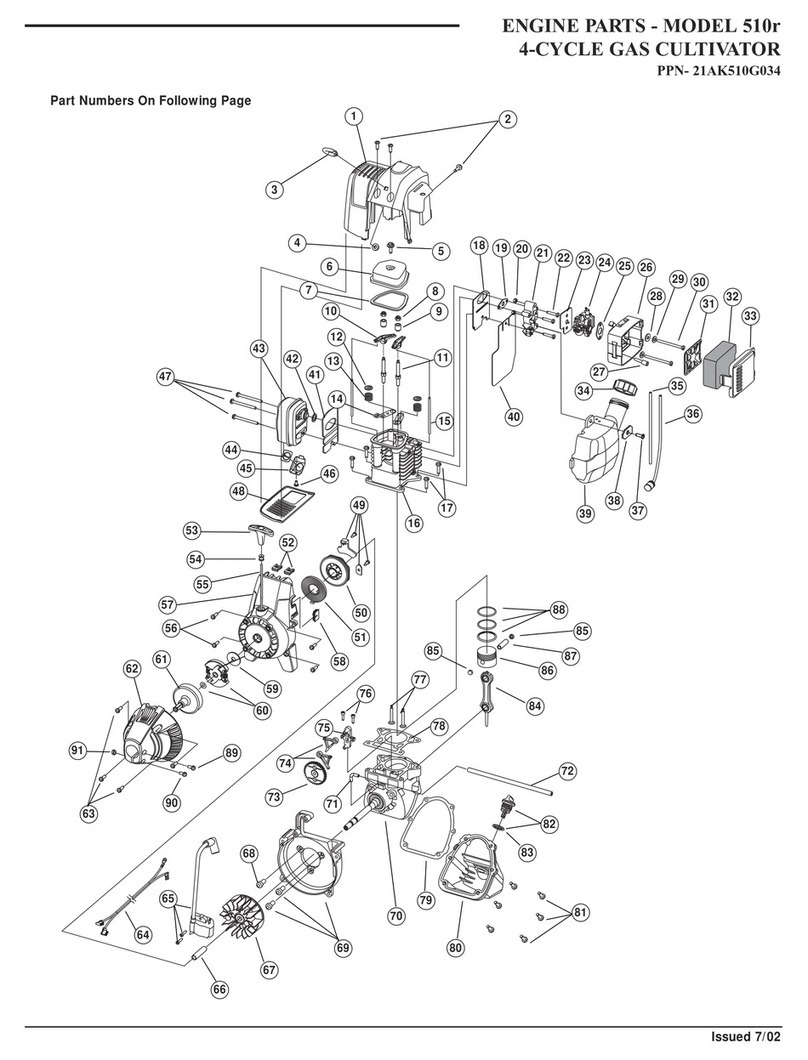

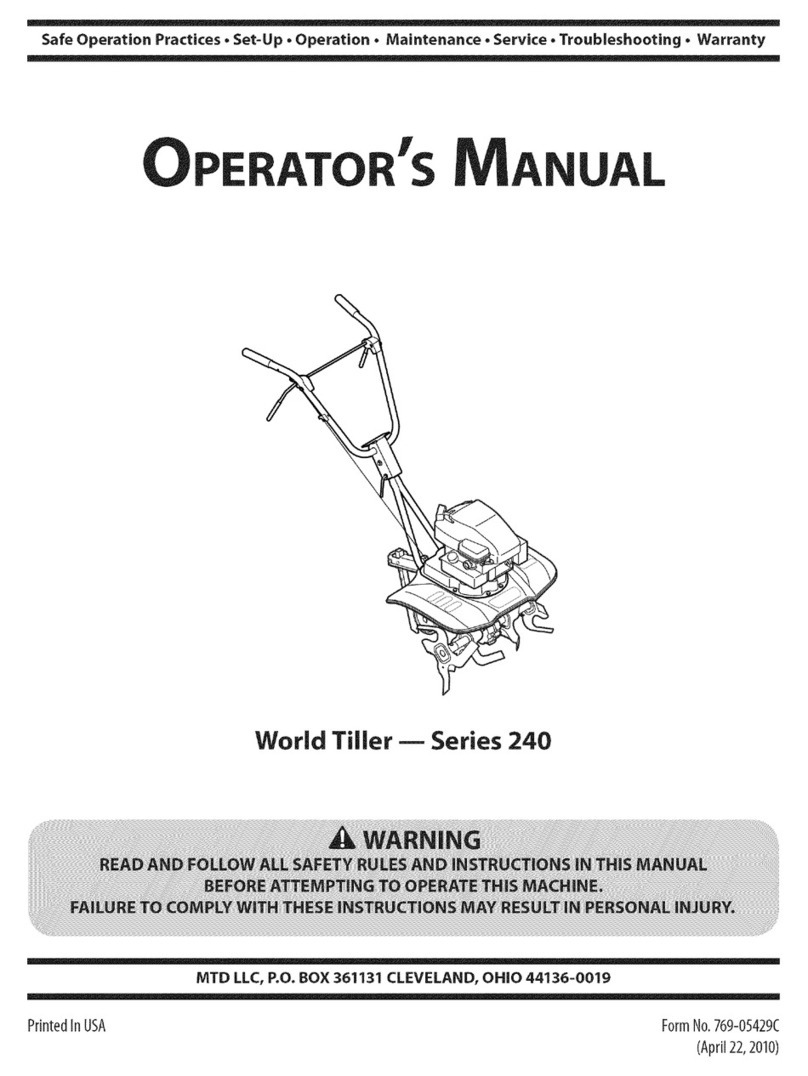

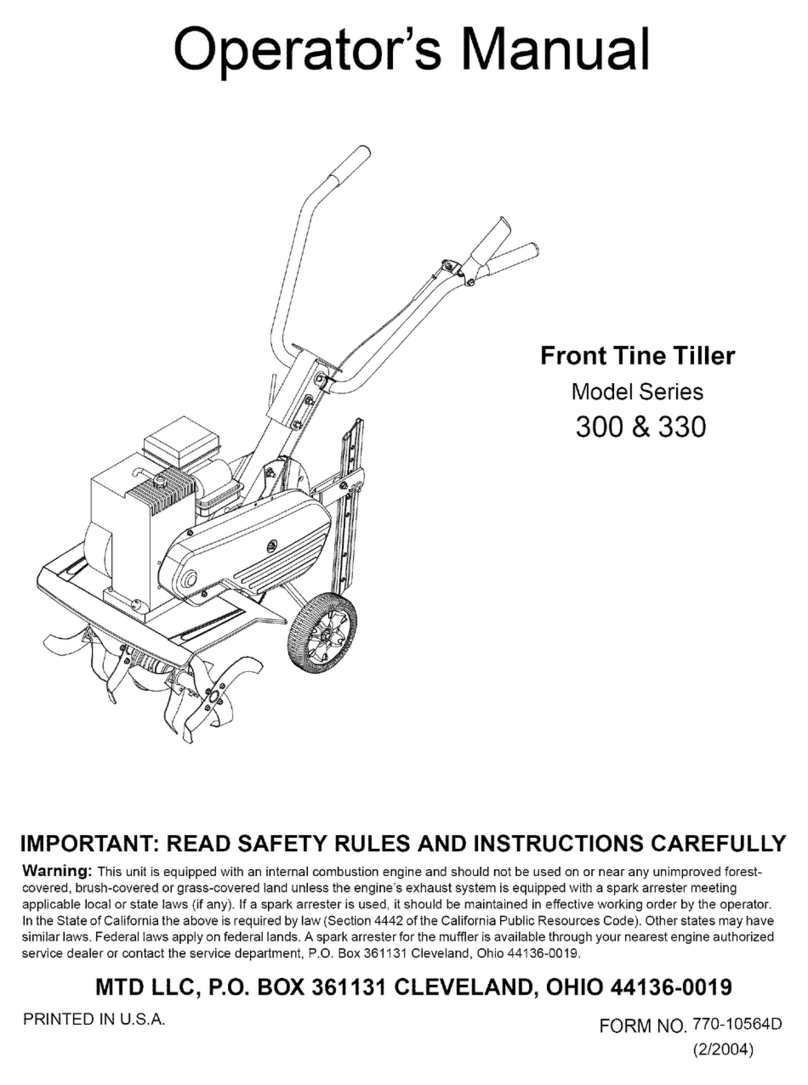

Other MTD Tiller manuals

Popular Tiller manuals by other brands

Troy-Bilt

Troy-Bilt OEM-290-260 Operator's manual

Scheppach

Scheppach MTP560 Translation from the original instruction manual

GARDEN WAY

GARDEN WAY 12194 owner's manual

Classen

Classen STAND-AER SA-25 Operator's manual and parts list

Craftsman

Craftsman 850 Series owner's manual

DR

DR PILOT 2 Safety & Operating Instructions