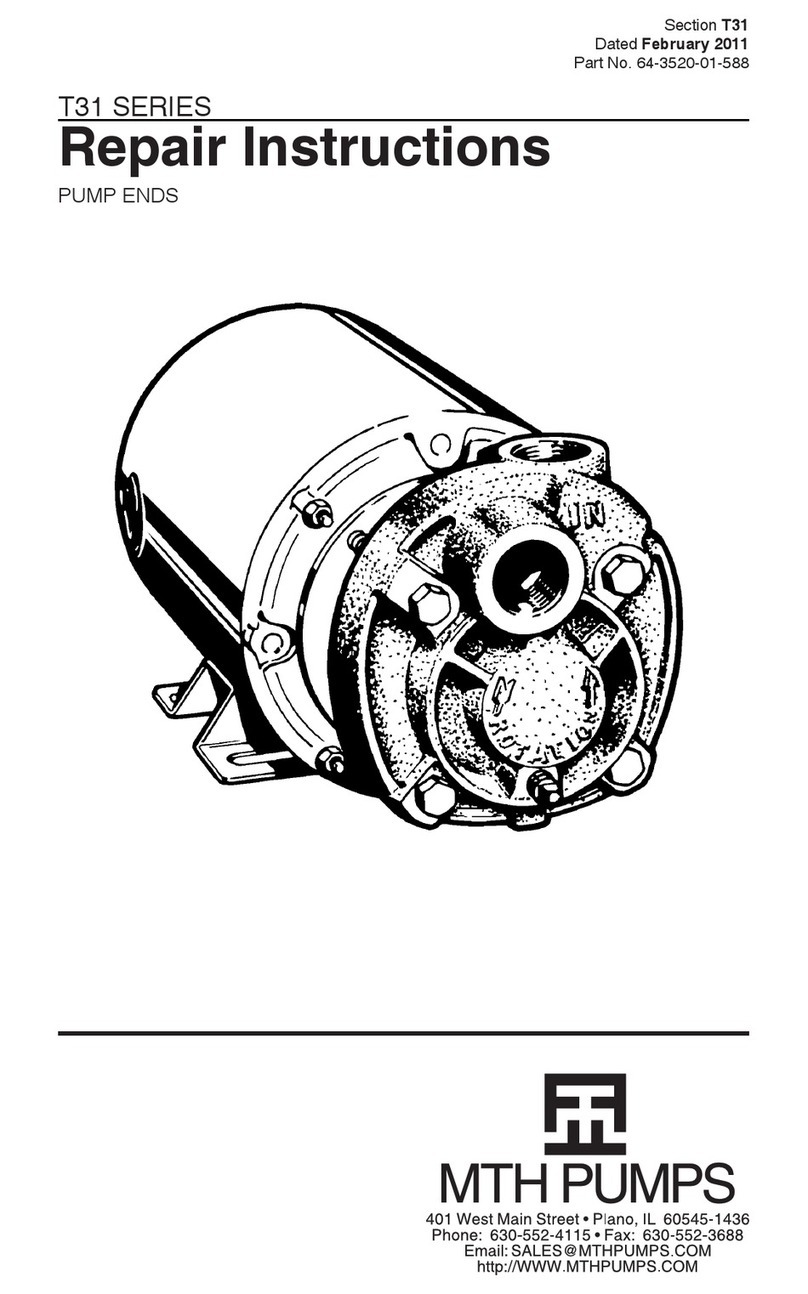

T31 SERIES

General Instructions

CLOSE COUPLED PUMPS

FLEXIBLE COUPLED PUMPS

A. Inspection of Equipment

B. Storage

C. Placing Stored Pumps Into

Service

D. ApplicationConsiderations

E. Recommended Spare Parts

When properly installed and given

reasonable care and maintenance,

regenerative turbine pumps should

operate satisfactorily for many years.

Because of the high differential pres-

sures expected in a regenerative turbine

pump, close running clearances are

used to reduce internal losses. Abrasive

particles, even microscopic ones in high

enough concentrations can open up the

close clearances between internal

cavities. For critical services it is

recommended that you keep an identical

pump for stand-by use.

1A Inspection of Equipment

Immediately upon receipt of the

shipment, inspect the equipment for

damage or missing components. Check

the shipping manifest and report any

damage or shortage to the Transporta-

tion Company’s local agent.

Put the instructions that came with the

shipment in a safe place where they will

be available to those who will be using

them for installation and service.

1B Storage

If the pump is to be stored before use, it

should be inspected as described in 1A,

recrated and stored in a dry location.

Standard shipping containers are not

suitable for outdoor storage. In some

areas, it may be necessary to cover the

pump's exterior surface with oil or other

rust inhibiting coating.

For storage beyond 30 days, Thylene

Glycol or another protective fluid must

be used inside the pump. Fluids used in

the pump should be selected for

compatibility with the pumps materials.

This is very important when optional

seal and gasket materials have been

used. Protective caps on the inlet and

outlets should also be used. Caps alone

are not sufficient protection.

1C Placing Stored Pumps Into Service

Special care must be taken when placing

stored pumps into service. First clean the

outside and flush out the inside. Try to turn

the pump using the shaft. If the impeller

does not break loose immediately, fill the

pump with water and try again in a few

hours. If this doesn't work, refer to

disassembly/reassembly instructions in

Section 5. Loosen the thrubolts clamping

the assembly together, three full turns, no

more. Fill the pump with water. Apply

torque, 50 foot pounds maximum, to the

shaft.

On close coupled units, access to the shaft

is between the pump and motor. A vise

grip or other plier type gripping device

may be used directly on the shaft.

Applying torque to the motor fan blades is

not recommended.

The pump should turn before the 50 foot

pounds is reached. Continue turning the

pump while tightening the thrubolts to their

original positions.

1D Application Considerations

1D1 Electrical Wiring

All electrical equipment and wiring should

conform to Local and National Electrical

Codes. Use the motor manufacturer’s

instructions for connecting the motor.

Note the correct rotation and wiring

diagrams on the assembly. Make sure the

motor rotation and speed matches that

required for the pump.

1D2 Construction Materials

While it is reasonable to assume that good

judgement has been used in selecting all

the materials in the pump for compatibility

with process fluids, actual conditions

sometimes vary from original expectations.

Also, typical material selection charts do

not consider all the temperature, pressure,

and fluid variables. The customer’s

engineer should be consulted for final

judgement on the best materials for critical

process applications.

1D3 Valves

The first valve to be considered for a

regenerative turbine pumping system

might be a pressure relief valve. Because

this type of pump has a horsepower

requirement similar to that of a positive

displacement pump (constantly rising

along with a pressure increase) a relief

valve can be effectively used to limit

horsepower. This is helpful when a non-

overloading motor is specified. It can be

of critical importance if the system flow

rate can vary widely. There are almost

no circumstances where a flow modulat-

ing valve will work successfully in a

regenerative turbine pumping system.

The steep pumping characteristic,

typical of these pumps, produces very

large pressure changes with small

variations in flow rate. As a result, the

modulating flow from the valve introduc-

es sharp pressure shock waves that

shorten pump life and may cause

damage in other pieces of equipment in

the system.

If a shutoff valve is necessary in the

suction line, use a gate, ball, butterfly, or

other full port valve. Globe or other flow

restricting valves can in some cases

reduce pump flow or increase chances

of cavitation.

A swing check valve is recommended in

the suction line even when the pump

inlet is only slightly higher than the fluid

source. It should be the same size as

the pump inlet or sized based on

reasonable fluid friction losses.

A foot valve is recommended when

lifting fluid from a sump. This will save

wear and tear on any pump, even those

equipped with self priming equipment.

A Y-Strainer is recommended immedi-

ately ahead of the pump on any newly

constructed system. This is advisable

due to the probability that foreign

material large enough to damage pump

clearances may remain even though the

piping has been flushed.

Valves in the outlet piping of a regenera-

tive turbine pump should always be

open as far as possible when the pump

is started. This will reduce the start-up

load on the pump and motor. Never

start the pump with the discharge

valve closed.

Inlet valving should be open when

starting any pumping system. Without

some fluid in the pump, it can gall and

lock up impellers. Violent pump failure

will result from continued operation

with the inlet valve closed.

1D4 Priming

Regardless of whether self-priming

equipment is used or not, always fill the

pump and vent it of air for best seal and

1.

Page 502