Service Information

Service Schedule

The manufacturer recommends that the following service procedure should be performed at each machine’s

scheduled service interval.

Service Procedure

1. Perform a visual inspection; include the following:

a) Control unit

b) Wiring connections and looms

c) Fire suppression tank pressure switch (low)

d) Fire suppression tank pressure switch (discharge)

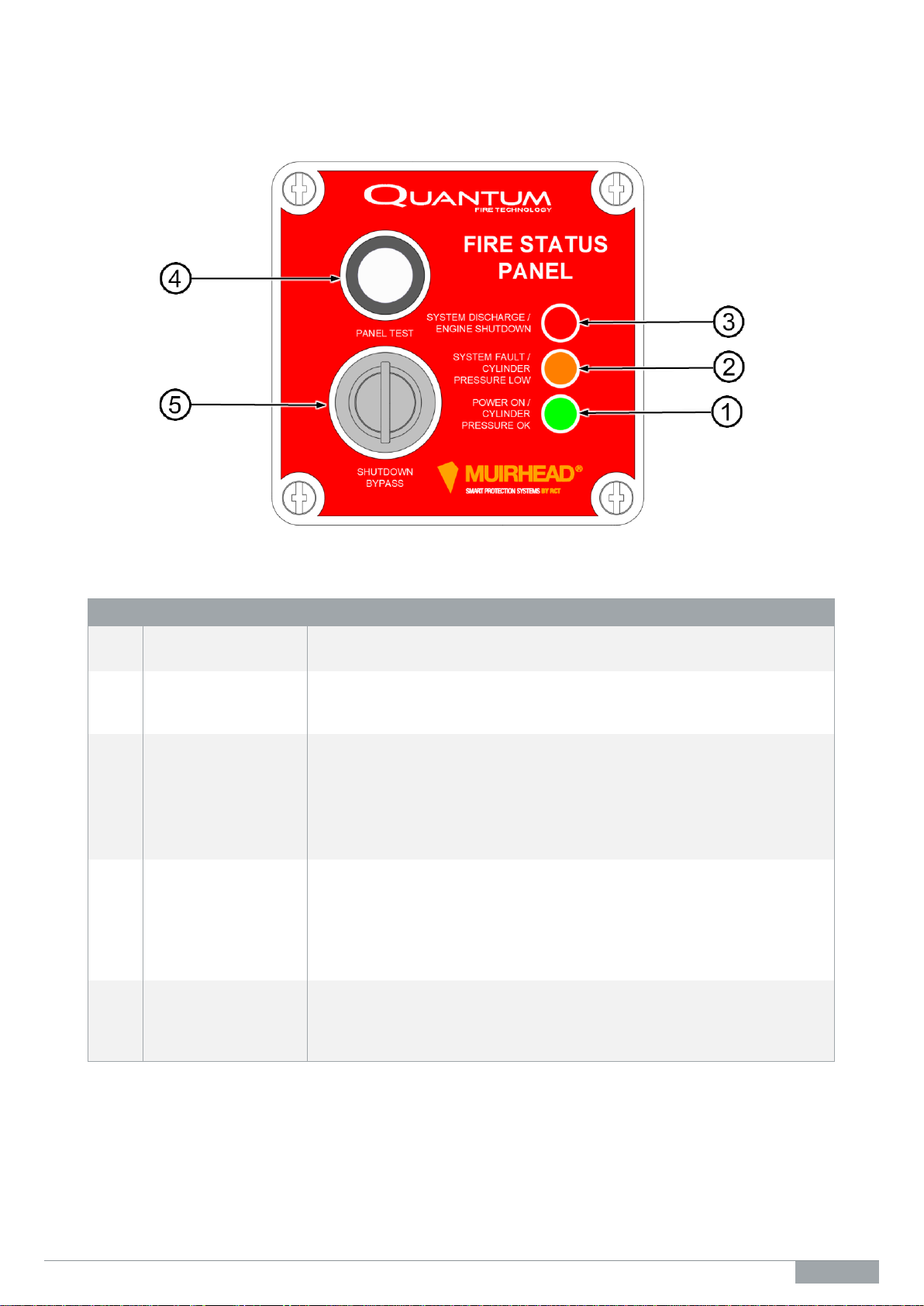

2. Perform a system test as per the following:

a) Turn the ignition key to the on position and with the cylinder pressure correct, the alert indicator will

illuminate green. The output to the ETR circuit will be activated.

b) Turn the ignition key to the off position and with the cylinder pressure correct, the green alert indicator

and ETR output will turn off. The auxiliary output will turn on.

c) Push and hold the panel test button. The green alert indicator will turn off and the amber alert indicator

will turn on for two seconds. The red alert indicator will switch on after the pre-set period. The ETR

output will turn off and the auxiliary output will turn on. The alarm will be active in this state. When the

panel test button is released, the system will revert to the run state.

d) To check the low cylinder pressure circuit, open circuit the wire at input 1 pressure switch (1200 kPa).

When open, the green alert indicator will switch off, the amber alert indicator will switch on and the

alarm will pulse on and then off. In this state, the alarm will pulse every 30 seconds.

e) To check the cylinder discharged circuit, open circuit the wire at input 2 cylinder discharged pressure

switch. The red alert indicator will switch on and the alarm will be active and pulse for last two seconds

prior to shutdown. Once the shutdown has occurred, the alarm will stay active.

f) Repeat part (e) but push the panel test button during the six-second cycle. This will extend the

shutdown for 20 seconds. During this override period, the alarm will stay active. The delay extension

will only operate once.

g) Once part (f) is performed, insert the key into the key switch and turn to activate it. This will override

the ETR circuit only. The alarm will stay active.

Note

1. Once the system test has been completed, turn the key switch off and ensure all wiring is reconnected to

the original position. Refer to the external wiring diagram in this manual.

2. Once the following has been completed;

a) system has been discharged, or

b) a discharged test has been carried out, AND the ETR output has switched off (shutting down the

machine), then,

the battery power to the unit must be cycled to reset the system.

Turning the ignition on and off WILL NOT RESET the system.

Parts List