Before operating machine ensure that PTO flow has been adjusted correctly. Flow guidelines

outlined below.

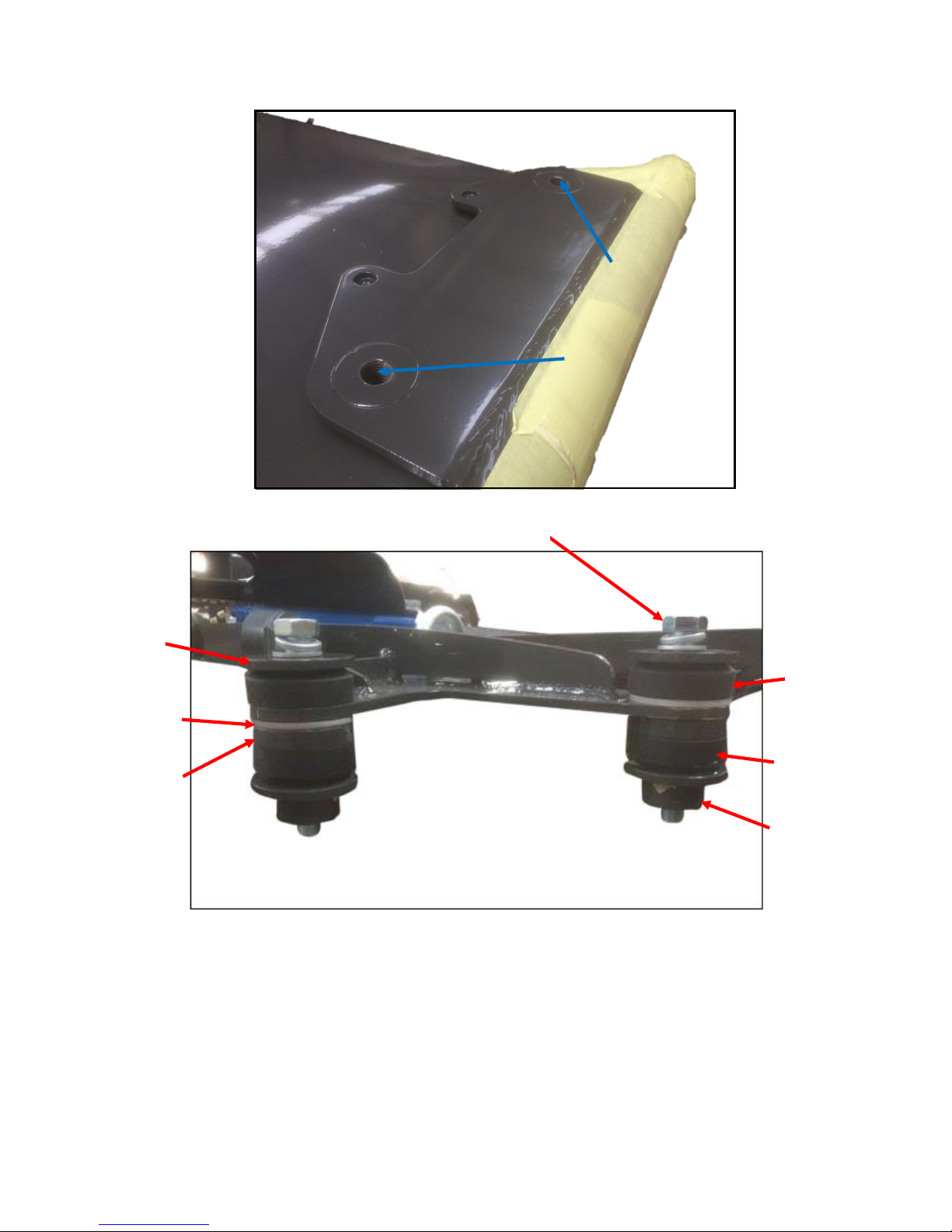

1. Open machine RH rear chassis panel to gain access to the PTO Needle Valve shown

above in Fig. 9.The needle valve is behing the splitter box

2. Screw needle valve completely out.

3. Check Charts above in Fig. 9 for adjustment data to suit the specific pump fitted to

the machine.

4. The needle valve needs to be setup to achieve approx. 40L/min to operate the Cityvac

attachment properly.

5. If the machine has a 35cc pump screw the needle valve in 6 ¾ turns (shown above).

6. If the machine has an 18cc pump screw the needle valve in 5 ¾ turns (shown above).

7. The machine will reach sufficient suction at 1250 RPM.

Once setup properly excessive acceleration will have no impact on the flowrate being sent

to the cityvac attachment.Figures above are guideline only and a flowmeter must be used

for accurate flow control.

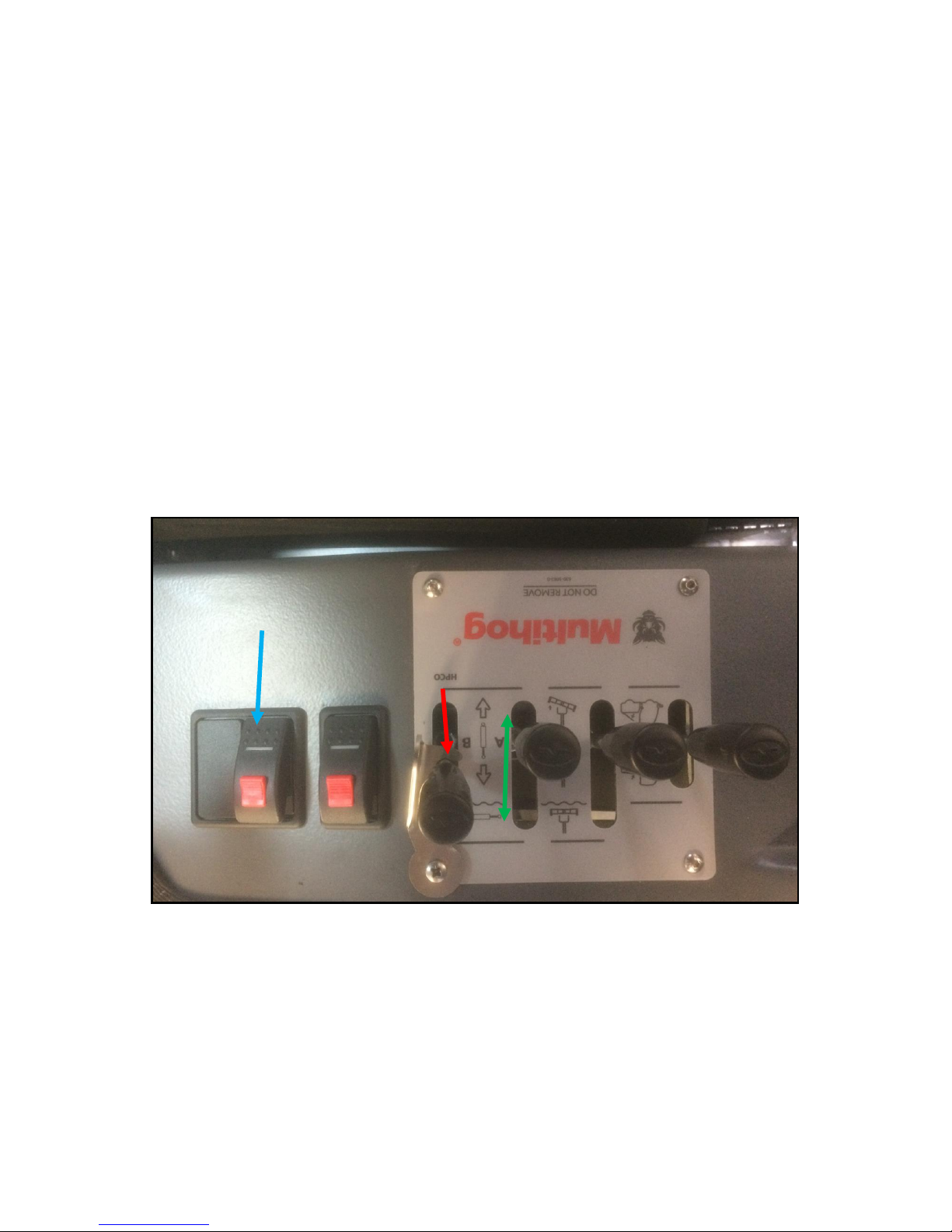

FIG. 10

To operate the Cityvac follow the procedure outlined below.

1. (HPCO) Engage lever B outlined in red and lock in place to operate the high pressure

carry over and send oil supply to the valve block on the rear attachment. This

operates supplies oil to the trunk cylinders.

2. (FAN) Turn on the fan by pressure the PTO button highlighted in blue above.

3. (Tip Cyl.) To operate the Tipping Cylinders, use lever A highlighted in green above.