1. ystem Application

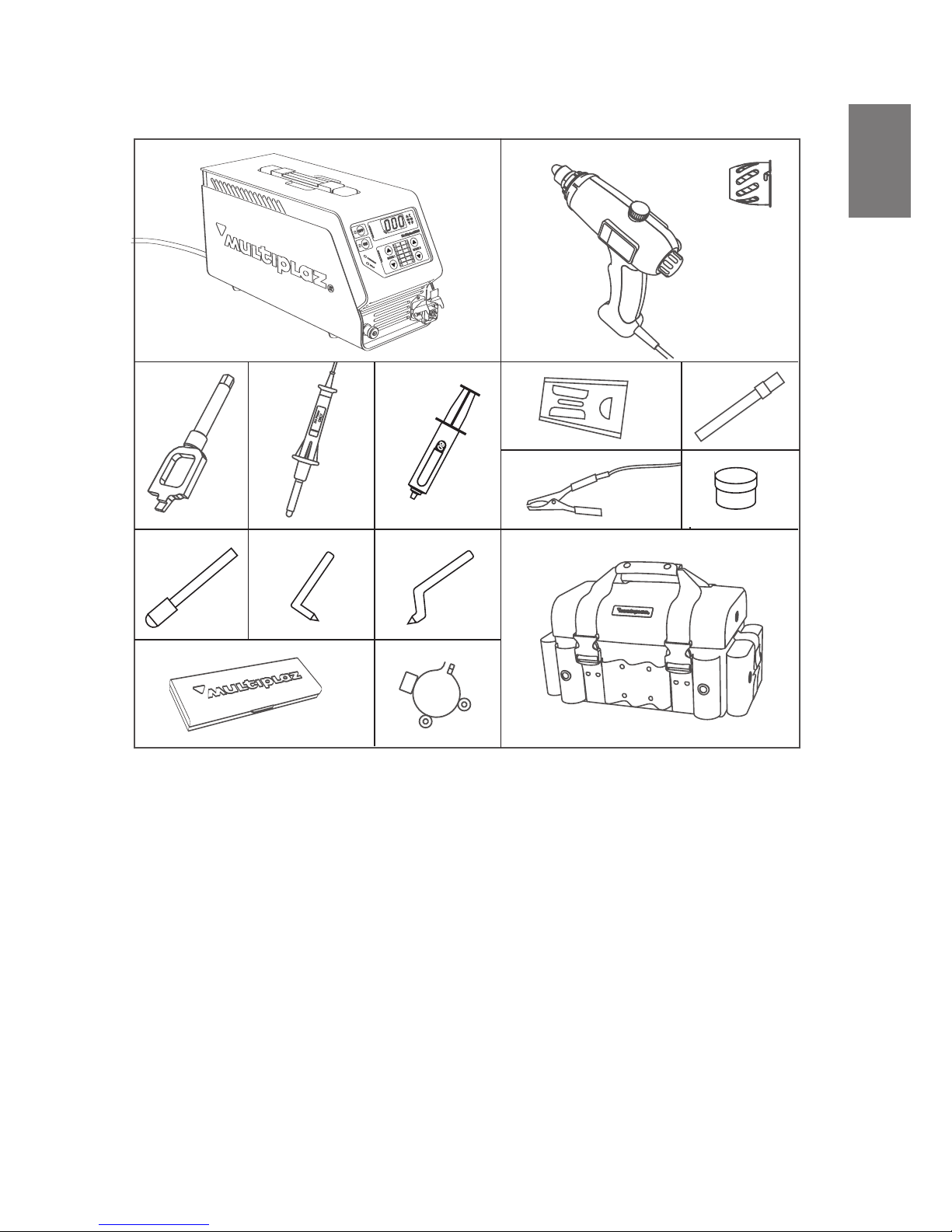

The Multiplaz-3500 portable system is designed for manual plasma cutting, welding,

soldering, braze welding, and brazing (joining of dissimilar metals) of ferrous and non-

ferrous metals including alloyed and unalloyed steels, cast iron, copper and copper-

base metals, stainless steel, aluminum and aluminum alloys The system can be used

to perform separation plasma cutting of various nonconductive nonflammable materials

including cement, concrete, brick, haydite aggregate, quartz glass, etc.

(ethanol)

es

of

er

Caution

The circuit breaker in the wall receptacle circuit should be rated for at least 25 for

110V and at least 16A for 220V

1. pecifications

4 S

.

,

The device works from the household electric system, using for welding and brazing a

water solution of ethyl alcohol , and for cutting just water. The device can work

on any water, and quality of welding and cutting do not depend on quality of water.

However, to increase service life and simplification of maintenance service, it is better

to use water with small amount of minerals, the best is distilled water.

!

А

.

5 S

Electrical Supply V (single phase ............ ...........

Supply Frequency Hz .............

Maximum Power Requirement, KWt .... for network voltage 220V

Power Supply Weight kg

Torch Weight dry kg .................... ...

Liquid Consumption, liters hour......... ....... .

Idle Voltage, V (not to exceed)....................

Torch Steam Pressure, bar...... ..

Duty Cycle

Power Supply Dimensions (l x h x w) mm................

Torch Dimensions (l x h x w) mm.............. .

Power Cable Length m.....

Torch Cable Length m... ..

, ) ............................... ........

, . ...................................................................

...... .......

, ..........................................................................

( ), . .............................................. ............

/ .................... ...................... ........

...............................................

........................................................... ....

, .................................

, ..................................... .........

, ........................................................................

, ................................................................. .........

for network voltage 110V

, %............................. ..

(l x h x w) inch................

(l x h x w) inch................ .............

.......

........................................................... ....

, ................................

, ................................

............1 -2

... ............50-60

............3

........................8

.................. .. 9

.................. ,25

...................... 8

..... ......... ,4-1,2

.380 х190 х140

х

........................2

........ ...........

00 53

..

......... .5

......... 2.0

. 0,

0

6

. 0

....................100

.15,0 x 7,5 x 5,5

..205 194 60

....8,1 x 7,4 2,4

..... 2

............

.х х

8

1

418

6.

.

Copper and Copper-Base Metal Welding and Braze welding Technology

Copper fillers, copper-zinc fillers, copper-phosphorous fillers, and specialized fluxes are used in the course of welding and braze

welding

It is best to use simple water rather than a water/alcohol mixture and preliminary heating of workpiece for braze welding of copper.

( , , .)

.

Copper Brass Bronze, etc

Welding and braze welding modes are shown in Table 5

Table 5 Copper and Copper-Base Metal Welding and Braze Welding.

*.Ethanol concentration in water/alcohol mixture is shown in parentheses

** .This process uses simple water

Material Workpiece

Geometry

Primary

Dimension mm, Type of

Process

Filler Diameter

mm

,

Flux MODE I /

MODE II

Control Setting

V

,

None 2 / 4

3 / 4

160 - 180

150 - 170

2

d

d

= 5

= 5

Copper Wire

+

Copper

Copper

Busbar

+

Busbar

None 1 /

2 /

off

off

160 - 190

150 - 170

2 5.

d

d

= 1 2

= 1 2

.

.

Welding

(50%)*

+

Brass

Brass

Plate

Plate

+

1 /

2 /

off

off

160 - 190

150 - 170

2 5.

d

d

= 1 2

= 1 2

.

.

Welding

(50%)

+

Brass

Brass

Plate

Plate

+

None 1 /

2 /

off

off

160 - 190

150 - 170

3

d

d

= 2 5

= 2 5

.

.

Braze welding

(50%)

Copper

Copper

+

Plate

Plate

+

None 2 / 4

3 / 4

160 - 180

150 - 170

2

d

d

= 6

= 6

Butt Welding**

+

Copper

Copper

Plate

Plate

+

Butt Welding**

None 2 / 4

3 / 4

160 - 180

150 - 170

2

d

d

= 4 5

= 4 5

.

.

Butt Welding**

Copper

+

Copper

Plate

Plate

+

Filler or Braze

Brass Wire

Copper Wire

Brass Wire

Copper Wire