4

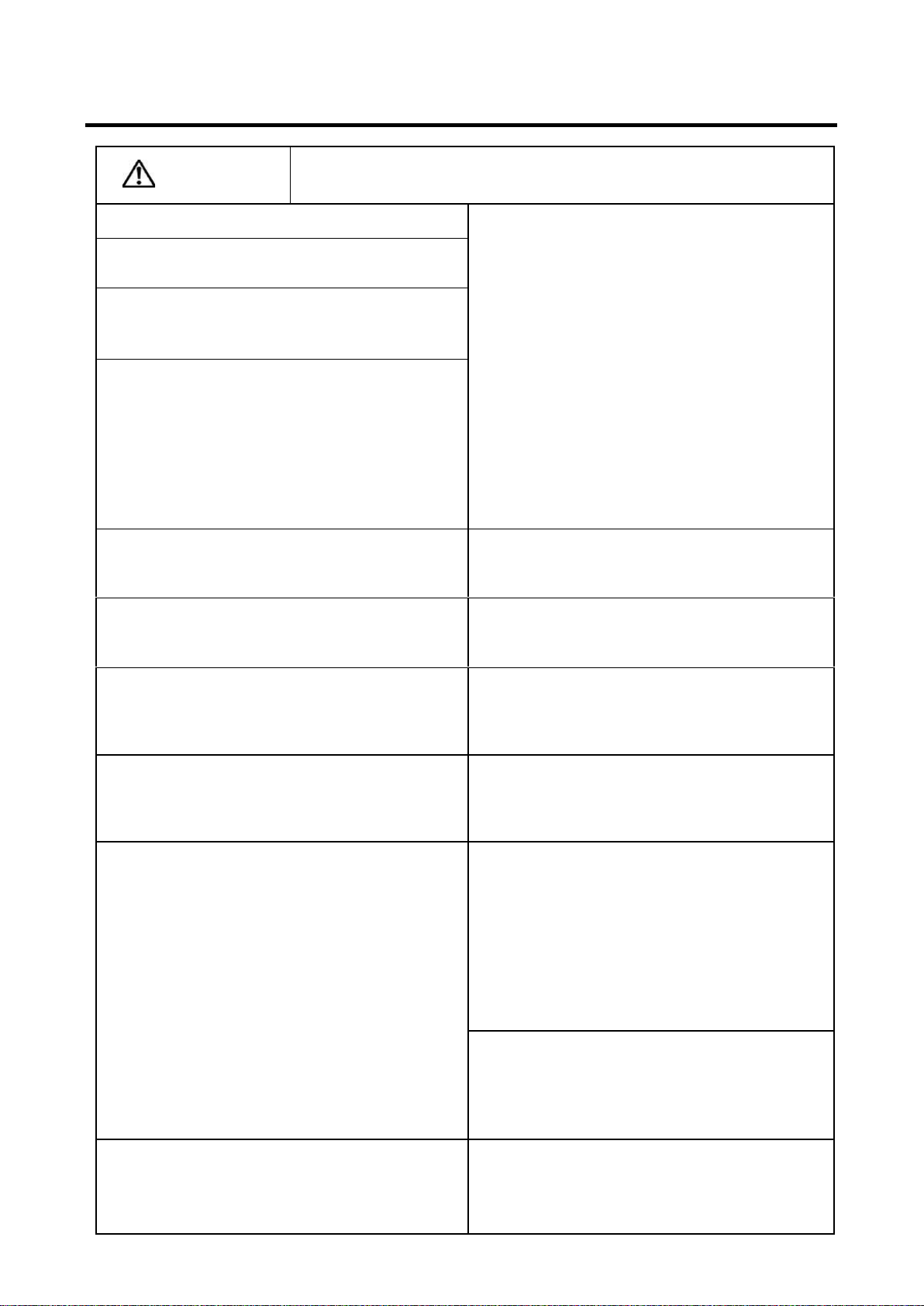

Handling Instructions and Cautions

Failure to follow the instructions shown below can lead to death or serious injury.

Any operations not described in this instruction manual are prohibited.

Be sure to read this manual to use the product safely. Be

sure to read this manual to use the product safely.

When using the power cord, follow the instructions below.

Use only the standard power cord that comes with the

product. Do not modify it.

Make sure that the power cord is free from heavy load

and excessive tension.

Be sure to hold the plug while pulling out the power

cord.

Before connecting the power cord, make sure that the

robot power is turned off. Fully insert the plug into the

power outlet.

Periodically clean the power cord plug to remove any

dust.

Be sure to unplug the power cord before fuse

replacement, inspection or lubrication.

Before connecting the power cord, make sure that the

robot power is turned off. Fully insert the plug into the

power outlet.

Failure to follow any of the above instructions may cause a fire,

electric shock, or injury.

Do NOT disassemble or modify this product.

This may cause fire, electric shock or injury. Contact the Musashi

Sales Department for repairs.

Do not bring the robot near to any fire, explosive matter, or

flammable/corrosive gas atmosphere. Do not wash the robot

with water.

Doing so may cause an explosion, fire or electric shock.

Do NOT use liquid solvents to clean the robot.

Some types of liquid may erase the product marking,

resulting in a product failure due to a connection error or

an unexpected injury.

Do NOT place this robot on an unstable location.

The product may fall and cause injury.

Use a power supply meeting the power supply

specifications (100 to 240 V AC, single phase, 50/60 Hz).

Failure to follow this instruction may cause a burnout, fire, or

electric shock.

Be sure to ground the robot (type D grounding).

Failure to ground may cause a fire, electric shock, injury,

desktop robot malfunction or damage.

When connecting the ground wire, make sure that each

connector is not loose, has no leaks and is connected

appropriately.

If this check is omitted, you may be exposed to danger.

When handling liquid materials, work most carefully

following the Material Safety Data Sheet (MSDS).

When any volatile liquid material is used, install an

appropriate ventilation system.

Volatile liquid may cause an adverse effect to human health.

When installing a Musashi dispensing device to the

desktop robot, install the holder unit according to the

installation example. (Please see p. 21.)

Otherwise the liquid material may be applied incorrectly,

causing an injury or machine damage.

To use any tool or work prepared by the customer, the

customer must conduct a risk assessment, implement

appropriate safety measures, and provide warning labels

for any residual risks.

Failure to do so may cause danger.

Do NOT touch the product with your hand or move your

face near its operating area during operation.

Doing so may cause an injury.

When using our desktop robot (SM300, 400, 500SX series,

SMΩX series) conforming to the Machine Directive in a region

requiring CE marking certification, also use the protective

cover (SMX-CV-DR-CE, SMX-CV-OP-CE) provided as our

standard option.

If you prepare another protection mechanism instead of our

protection cover, install an appropriate safety

fence/safeguard or provide an interlock mechanism

corresponding to the safety category 3 (please see p.249).

In addition, install an earth leakage breaker (rated current 10

A, rated voltage 100 to 240 V, rated breaking capacity 2.5 kA)

before the AC power outlet.

Failure to follow these instructions may cause a fire, electric

shock, injury or machine damage.

Before starting an operation or work, be sure to check the

following items.

Record the check results in a record sheet and store the

sheet.

There shall be no obstacle or person in the safeguard

area.

The [URGENCY STOP] or [EMERGENCY STOP] button

shall function correctly.

The interlock mechanism shall function correctly.

The fan at the back of the desktop robot shall operate.

If this check is omitted, you may be exposed to danger.

When the customer constructs an interlock mechanism,

the work must be performed only by a technician who is

familiar with the related safety standards as well as the

contents of this manual.

Failure to follow this instruction may cause an injury or

machine damage.

Do not put your hand under the head or the mounting unit.

Before taking out a work, confirm that all axes are located

at their origins.

If the Z axis lowers, your hand may be caught between the

head/head mounting unit and the work base/desktop robot main

body, resulting in an injury.

The robot surfaces may be hot.

When an optional temperature controlling work base is used,

there is a risk of being burnt depending on the setting.

Use protective gloves as necessary.

PK

Elektronik

Vertriebs

GmbH,

E-Mail:

[email protected],

Internet:

www.pkelektronik.com