Useful inks

The latest version of this doc and OM can always be found at http://thonk.co.uk/documents/eq/

A build thread on the Muffwiggler DIY forum can be found at this URL

Quickstart

If you're new to building with SMD components, skip to the detailed notes on the next page.

If you're an experienced SMD builder you'll probably want to skip the lengthy notes below, so

here's some things that will probably save you time when you're building this project.

•A detailed OM can be found on the last page of this document.

•The silk on the PC for diodes D1 & D2 does not show their polarity. The cathode for both

components is aligned towards the nearest edge of the PC , away from the power header.

There are pictures on page 16 that show this.

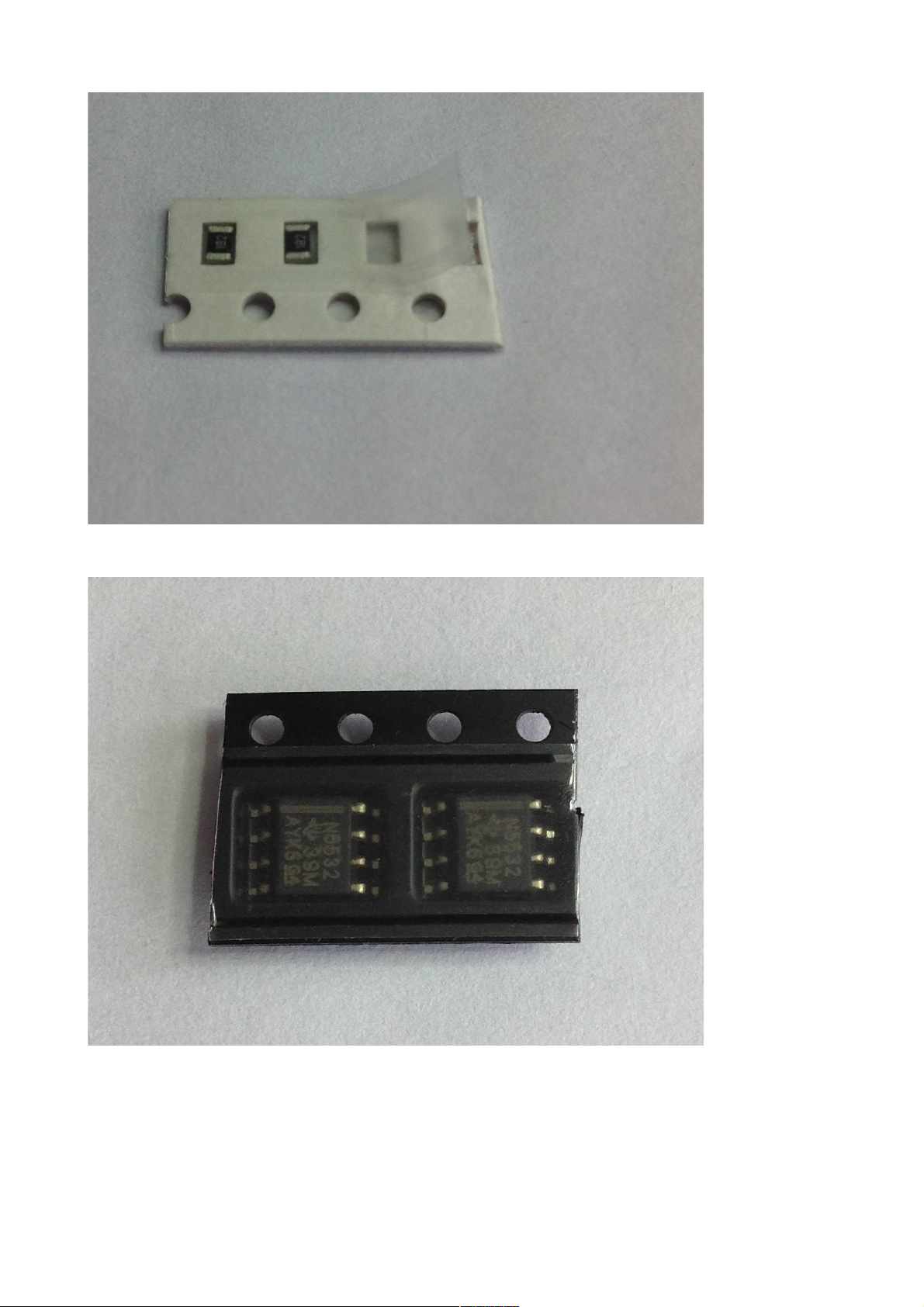

•The op-amps might not have pin 1 indicated by an adjacent dimple/dot in the package, or by

a semi-circular indentation at the end nearest pin 1/pin 8, as is common with through hole

ICs. SMD devices often have one of the longer sides with a sloped face, the other with a

vertical face. If you have such a device, pin 1 is the left-most pin of the side with the sloped

face when the device is pointing upwards. The silk screen on the PC shows both the

traditional circle next to pin 1 and also a line to indicate the orientation for devices with a

sloped face. Tthere are pictures on page 18 that show this.

•The suggested build order is to start with the components that have the lowest profile &

work upwards, so thats

◦resistors

◦non-polarised capacitors

◦diodes & PTC fuses

◦ICs

◦electrolytic capacitors

◦through hole components and panel

•It's suggested that you regularly stop to clean and inspect your work. It's much easier to re-

solder a joint when the board doesn't have the jacks and knobs fitted.

MTM SimpleEQ 0805 build doc v1.1 Page 2