Audio MusiKraft, Quebec, Canada / audiomusikraft.com / info@audiomusikraft.com rev. 10/2019

To cover a wide range sonic spectrum we have chosen and included in your kit three (3) tone wood

species with a desired finish which we found over the years perform very well and are versatile in

many situations. In the event that you would like to go deeper into your tonal explorations we offer

many more insert options as aftermarket parts which you can find in our web store. Or on special

order if you require more exotic woods or finish. If in need, we can guide you to make wise choices.

Wood species and their finish:

First of all, on all three (3) sets we have protected the external wood surfaces to help preserve the

wood

The Beeswax patina on the torrefied pine is used as surface preservation and to give color

richness to the appearance. Our beeswax treatment is insignificant to changing the sound.

We have chosen this wood so it slightly absorbs resonance feedback to the sensitive

cartridge generator. This is the most transparent sounding set in your kit. Pine is among

the smoothest woods which exist. To give you an idea, its density corresponds to

400kg/m3 on a scale which span approximately between 300 to 1150kg/m3 of all existing

woods.

Maple is considered a hard wood and widely used in musical instruments. Our numerous

listening tests showed us that its mechanical properties mixed with our lacquer coating are

more than favorable when the time comes to add a tad bit more edge, dryness and

impact to sound. Its density is 705kg/m3. Note: For sonic exploration, one can try the oil

treatment on any internal surface of the three (3) included sets but note that this test is

irreversible. The provided 1ml oil vial is to refresh the Ipe set factory treatment

(recommended once per year).

The thorough natural oil treatment on the Ipe tone woods serves as a wood resonance

dampener and adds a bit of tone in the sound. It also slightly darkens the background and

softens the Ipe top end. Ipe wood is very hard and is a proven species that works very well

when matched to our cartridges. Its corresponding density equals 1,100kg/m3

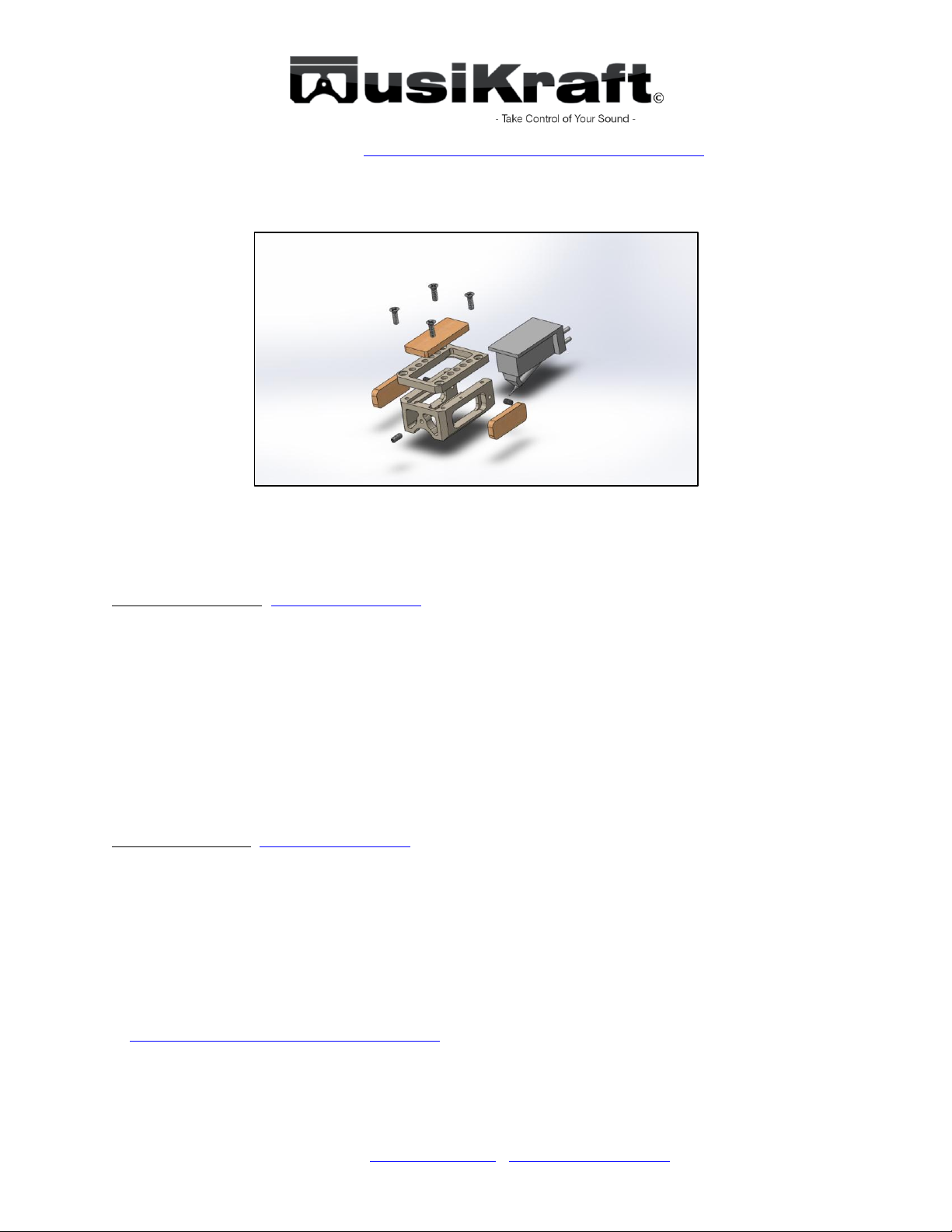

Caution: 1. - The motor must always be removed from the shell when doing such change. 2. - Be

careful not to lay your fingers on the side of motor when retrieving it out of the shell or during

manipulations as very fine wires are exposed. 3. - Be careful not to dent the external wood surface

with your finger nail.

Removing the wood inserts: (video supported help)

a) To free up the motor, first remove the tension on the lateral tuning-screws which could later

block the motor from being pulled out.

b) Unscrew and remove the four (4) flat headed Philips cover screws

c) By hand, remove the cover by pulling it upwards. The cover tongue and groove securely holds

it in place.

d) Flip the cartridge upside down on a flat surface (keep a finger on the motor’s back while doing

this so it doesn’t fall out of the shell)

e) Slip out the motor

f) With the help of the wooden pushrod, apply pressure on the edge of the internal surface of the

top insert so it comes out.

g) Proceed with the sides.