6

8. Connection to Power and Test run

(1) Check the nameplates ofblower and motorand confirm if they agree with the specification for

power supply, then connect to power line under instruction by electrical engineer and per

electric technicalstandardsandwiring regulation.

(2) Jog the blower and check the rotational direction is the same as the mark. If the rotational

direction is opposite, change the wiring connection. The direction can be reversed by

interchanging any two line leads. If the blower runs continuously with reverse rotational

direction,itcannotperformasspecifiedandmaylead to seriousaccident.

(3) Runtheblowerand measure the electriccurrent (averageof eachof3phase)ofthemotor. Ifit

exceeds the rated current, use at below the rated current by adjusting the air volume with

dumper and so on. After running for a while, if there is no abnormal vibration ornoise,test run

can be concluded. If any abnormality were found during test run, corrective action should be

takenreferringto“11. Troubleshooting”.

9. Precautions for Operation

Beforeoperating theblower, understand the following thoroughly.

(1) Continuoususeatsmallairvolumewillleadto fan durabilityproblem.

(2) The blower is designed to handle clean air. It cannot handle for air containing particulates and

dust, corrosive gases nor inflammable gases. A standard model can handle the air in the

rangeof -15 to 60 deg.C.

Pay attentionto following precautionincaseof thatheatresistantmodel operate.

(3) After starting the blower, temperature of the gas should be raised slowly. Otherwise the blower

may be strainedby heatexpansion.

(4) Whenstopping theblower,keeprunningituntilthetemperatureofthe blowerdescends nearly

roomtemperature.If the blower stops suddenly, the motormay be broken because the heatis

transmitted toit.

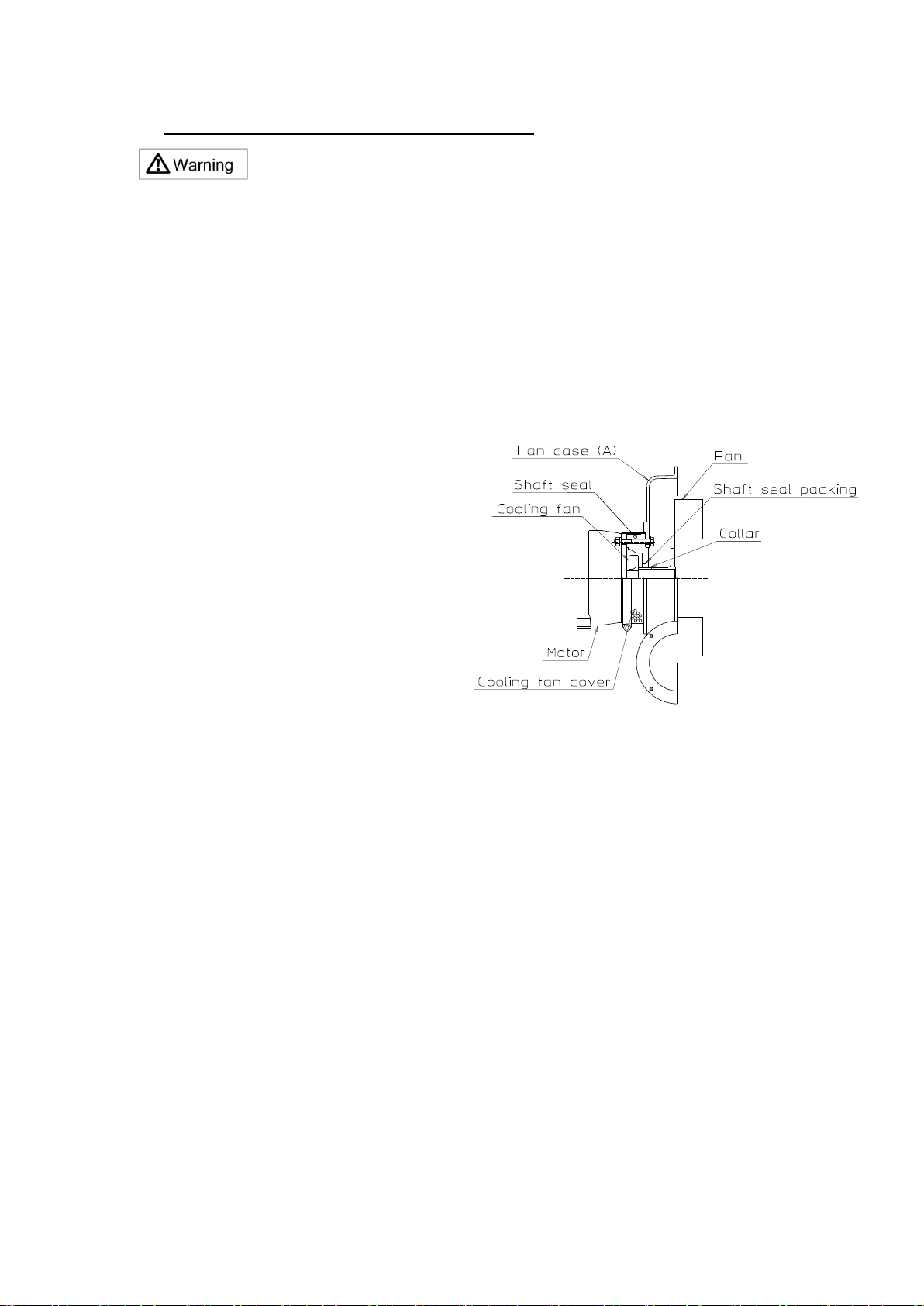

(5) Do not wrap the cooling fan cover in a heat insulator. Otherwise the life of the motor bearing

may be shortenedbecause the heatinsulatorpreventsheatloss.

10. Maintenance

Thefollowingmaintenanceis recommended tokeep thebloweringoodcondition.

(1) Payattentiontoventilation tokeeptheambienttemperatureintherangeof-15to 40deg.C.

(2) Pay attention to abnormal noise, abnormal vibration, abnormal temperature and air leakage. If

abnormalityis found,takeactions referringto“11.Troubleshooting”.

(3) The bearings that the motor only has are non-lubrication type. The life of the bearing is about

20,000hours,but thelifewill bedrasticallyshortenedifambienttemperatureis toohigh.

(4) If the blower has filter at the inlet, check the cleanliness of the filter periodically. Replace or

clean thefilter if and when the airfilter is notclean, as it causes pressure loss. The filter can be

washed by soaking into water or neutral detergents. (Wash it gently, do not rub or do not

squeeze it.)Lay thecleanerside upto dry. Itcanbecleanedforafew times with thismethod.