5

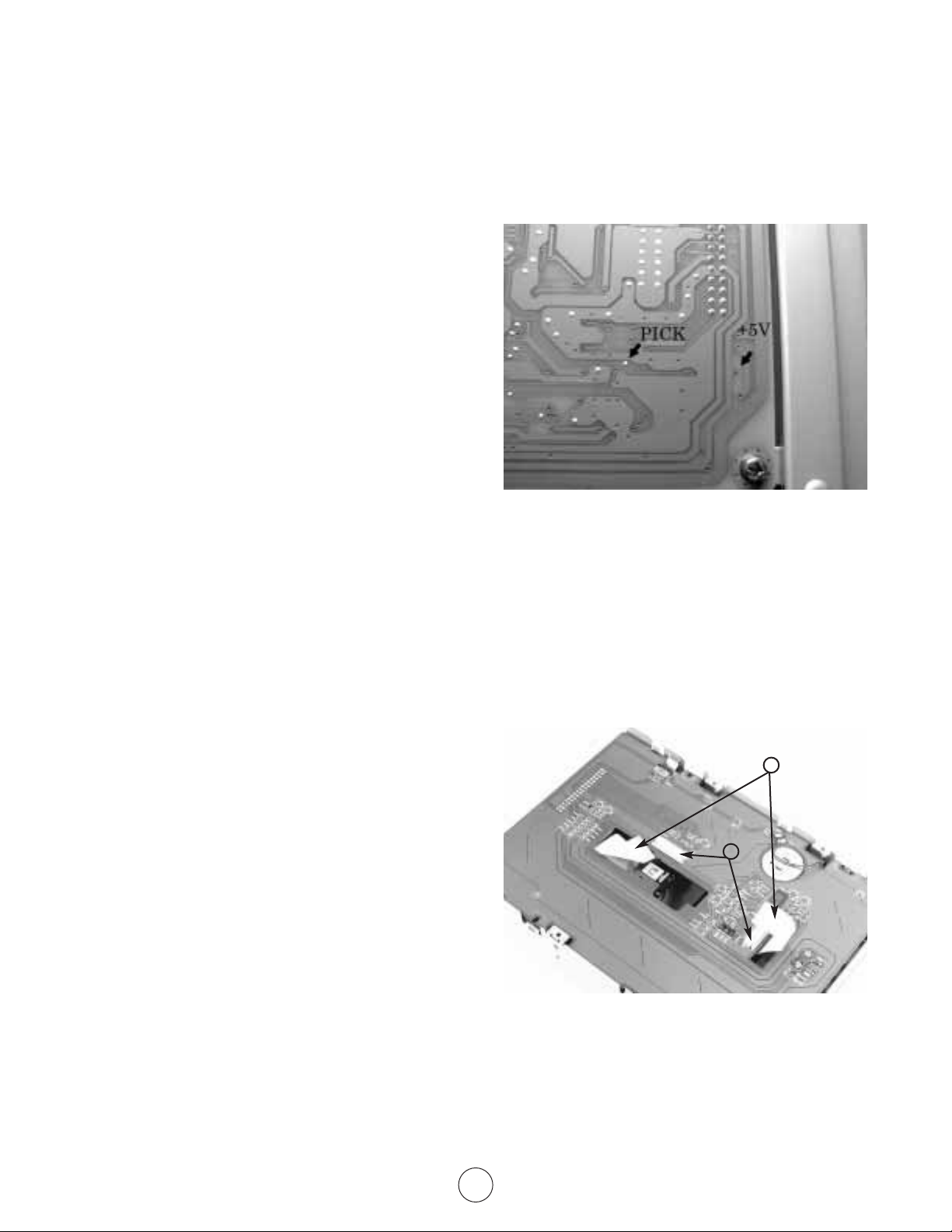

Measure the voltage across test points TP PICK

and TP +5 of the MAIN PCB to obtain the laser

diode current value in milliamps. When the

voltage exceeds 1.29 VDC (60 mA through

the parallel resistors R 201 and R 202), the

laser pickup must be replaced.

NOTE: This procedure only tests the laser diode.

There may be mechanical servo problems with

the laser pickup which can only be verified by

replacement of the laser pickup assembly.

Unlock two connector tabs (13) and disconnect

both flat flexible cables (FFC) (14).

CAUTION: Do not attempt to disconnect the

cables without unlocking the connector tabs or

damage may result.

laser diode test procedure

laser pickup replacement procedure

13

14