8

5. IMPORTANT INSTALLATION INFORMATION

nShower installation must be carried out by a

suitably qualified person and be in accordance with

BS 7671 (IEE wiring regulations) building regulations,

water regulations and or any specific local water

company regulations in force and should be in

accordance with BS EN 806.

nThis shower unit is designed to be connected to a

15mm cold water mains supply.

nTo make sure the heating elements are activated

the shower must be connected to mains water supply

with a minimum running pressure of 100kPa (15lb/

sq in) – 1 Bar at a minimum flow rate of 8 litres per

minute. The maximum static pressure is 1000kPa

(150lb/sq in) 10 Bar.

NOTE: For 9.5kW units the minimum running

pressure must be obtained at 9 L/min.

For 10.5kW units the minimum running

pressure must be obtained at 11 L/min.

nThe shower unit must not be fitted where it may

be exposed to frost, for example in an outdoor area.

The shower must not be used if suspected of being

frozen. Frost damage is not covered by the guarantee.

nPlumbers jointing compound must not be used.

In instances of difficult joints use P.T.F.E. Tape.

The use of jointing compound will invalidate the

product guarantee.

nDO NOT solder fittings near the shower unit

as heat can travel along pipe work and damage

components.

nDO complete all plumbing connections before

making the electrical connections.

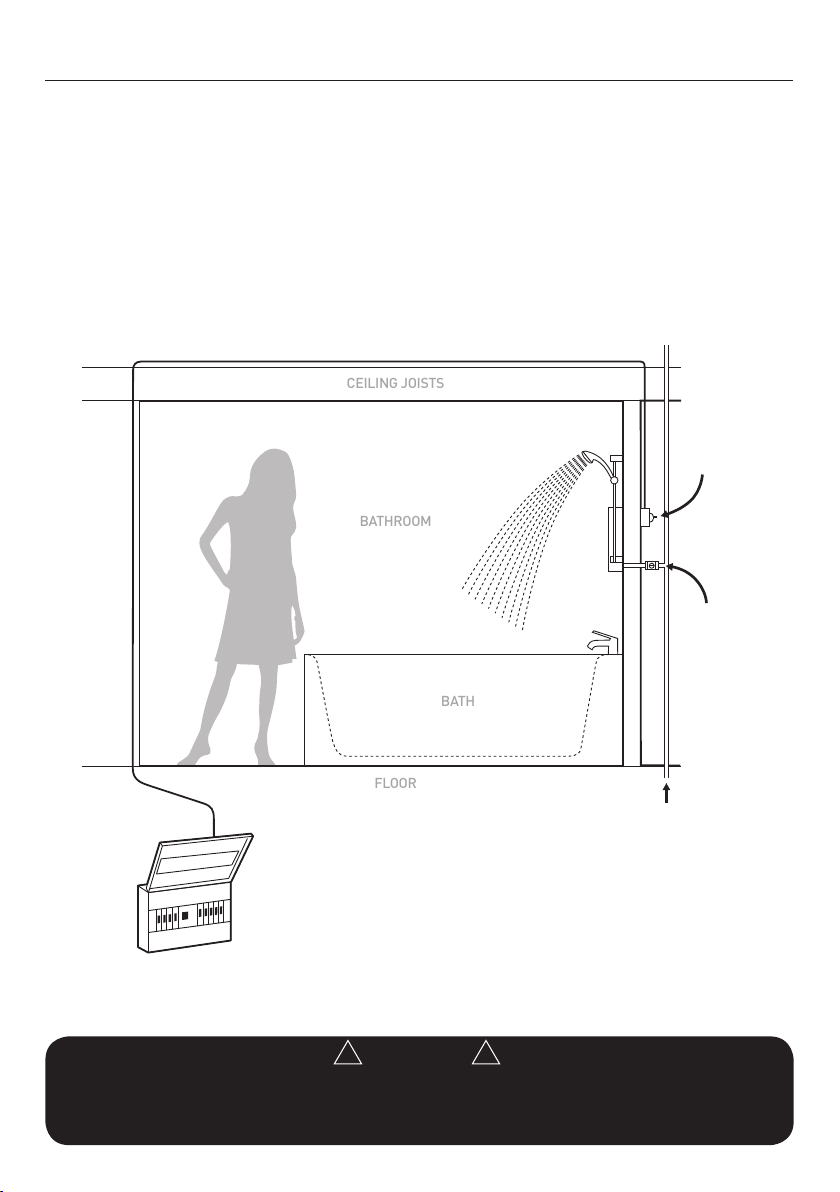

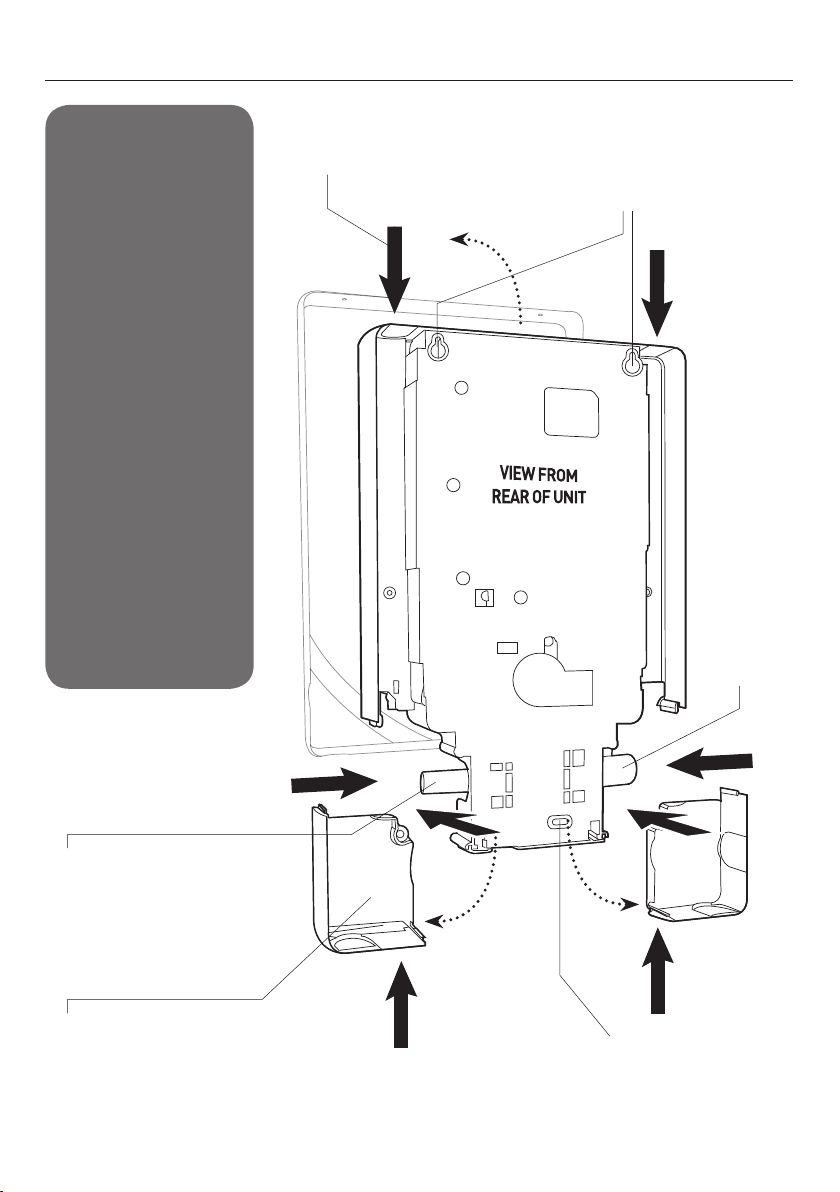

6. FIXING THE SHOWER TO THE WALL

Position your shower on the wall so that it will NOT

be in the direct water spray from the shower handset

when fixed.

You may wish to consider mounting the unit so that

the shower handset could be used over a sink for

washing hair.

The shower unit should be positioned so that the

shower head cannot be immersed in the bath or

shower tray when hanging down. A shower hose

retainer is supplied with the accessories (see pages

3 and 9).

The unit can be mounted at a lower level if required

for less abled users and for use with a shower seat.

Remove the four front cover fixing screws and lift

the cover off complete with the warmer (+) and

cooler (-) push buttons and flow control knob in

place. Note the connector and lead attached to the

control PCB mounted on the shower back plate.

This will require connecting to inside of the front

cover before completing the installation.

Having decided on the water and cable entry points

and chosen a flat piece of wall hold the shower

vertically against the wall and mark the top two

fixing holes.

Carefully drill the two holes as marked using a sharp

5.5mm masonry drill after first making certain there

are no pipes or wires behind the proposed holes.

Insert the wall plugs and screws provided leaving the

screw head proud by approximately 5mm. The shower

can now be hung on these screws.

Make sure that the shower is positioned vertically now

mark and drill the lower slotted fixing hole. Then fix

the shower to the wall. Do not fully tighten the screws

at this stage.

The shower back plate has moulded knock out

sections which are clearly indicated to allow the

chosen service entry option to be removed prior to

final fix.