2www.jainsusa.com ©2011 Jain Irrigation, Inc.

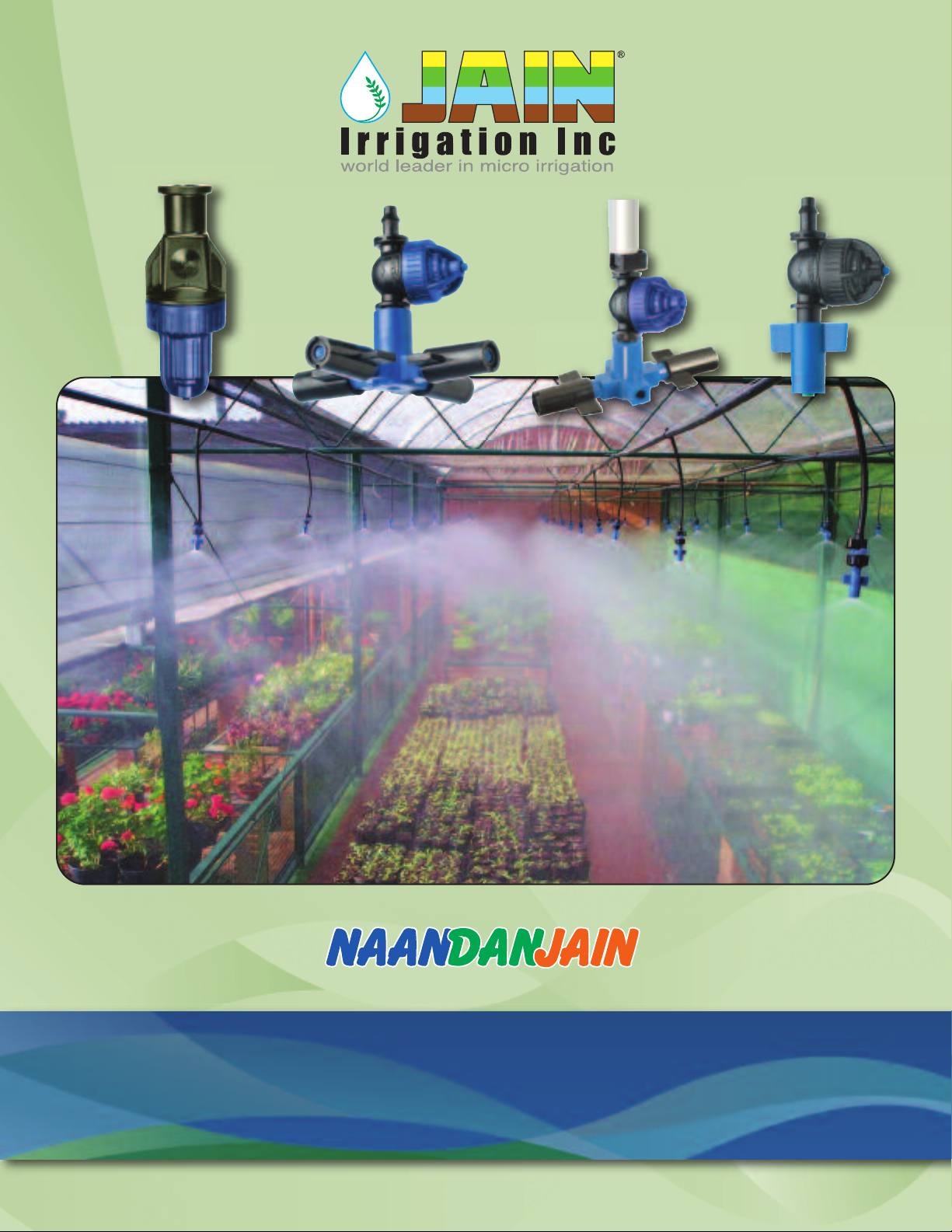

Dan Fogger/Mister

Dan Fogger/Mister

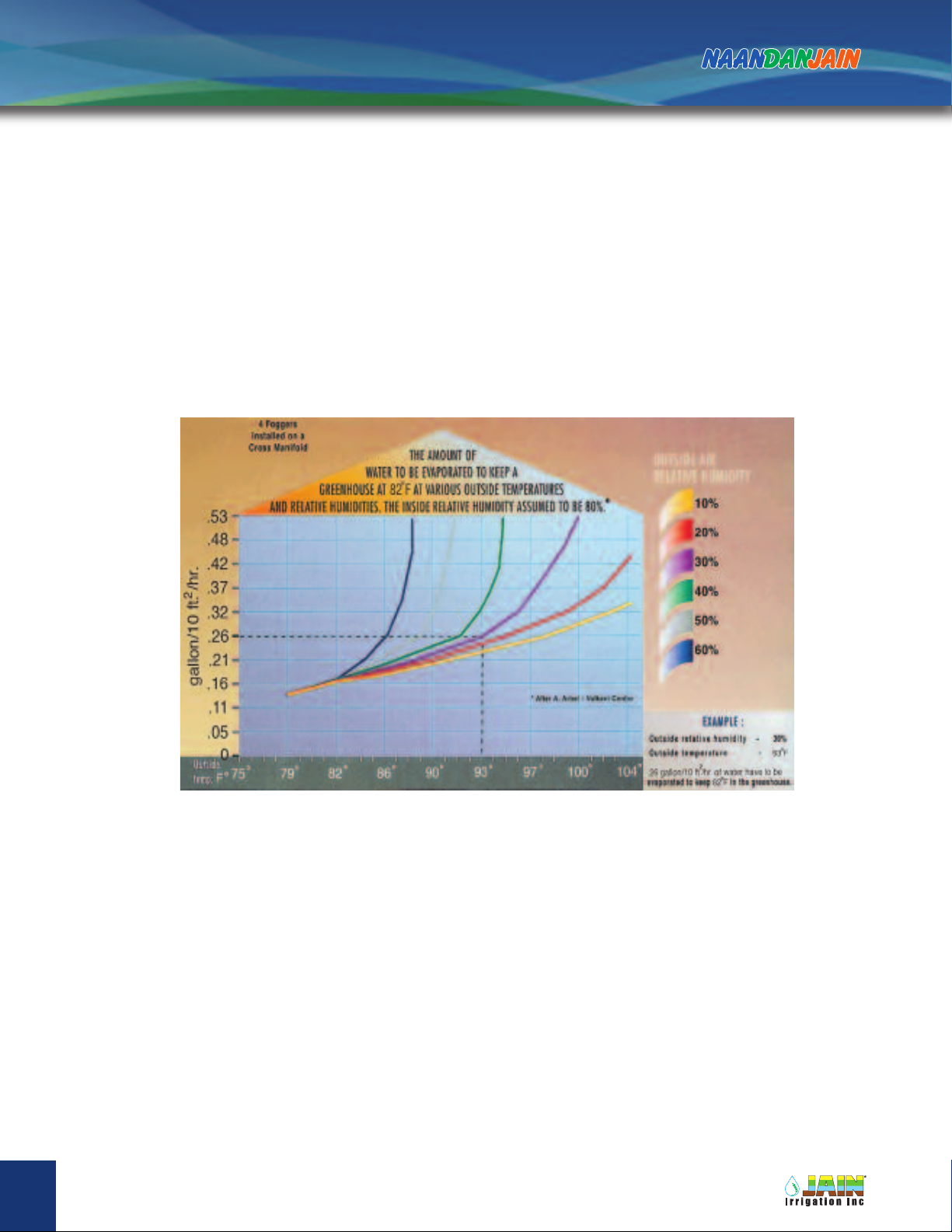

Dan Foggers provide a superior and consistent c imate contro of temperature and humidity

for greenhouse app ications.The average fog drop et size is 90 microns at 58 psi. Foggers are

used for coo ing, humidifying, cutting propagation and seed germination.

Product Features

■Reduces greenhouse temperature

■Increases greenhouse humidity

■Provides perfect conditions for p ant propagation and seed germination

■Extra fine drop et size (average 90 microns @58 psi)

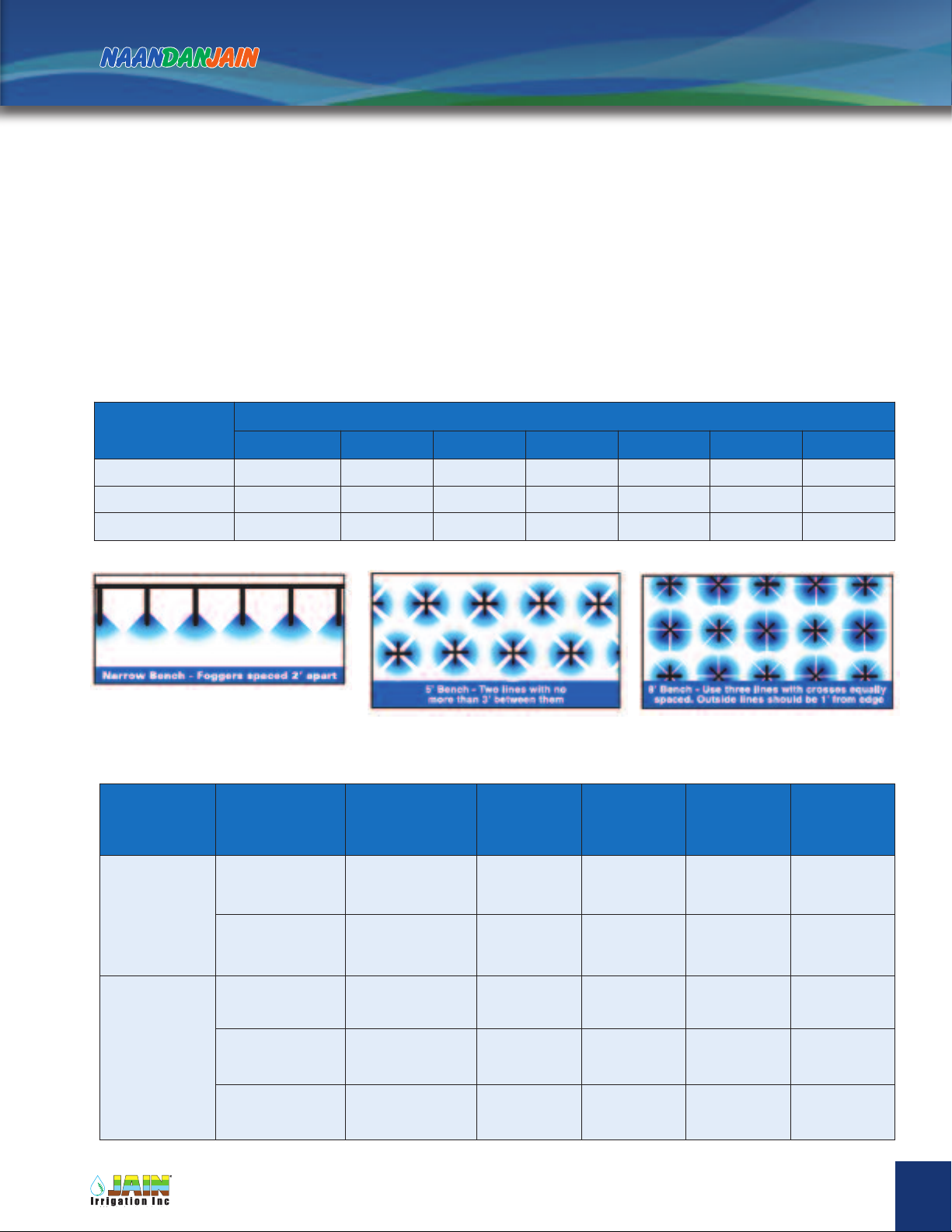

■Avai ab e with 4 f ow rate nozz es for different precipitation rates

■Avai ab e in 4 configurations, sing e nozz e, 4-way cross (4 nozz es),2-way Tee (2 nozz es),

and Super Fogger (2-way Tee with bui t-in 2 nozz es)

■Optiona p ug a ows one or more nozz es to be capped. Insta ed near the edge, end of a

ine, or against the wa of a structure

■A units start-up and /or shut-down simu taneous y when used with Leak Prevention

Device (LPD)

■Easy to assemb e and insta

■Easi y disassemb ed for c eaning and maintenance

■Recommended fi tration 120 mesh

■Made of durab e p astic for ong term operations

■C og resistant due to wide water passages

■Easi y retrofits existing fogger systems

Applications

■Evaporative coo ing and humidifying contro for Greenhouse and High tunne s

■Seed germination and cutting propagation

■Livestock coo ing

■Chemica app ication – using the Super Fogger (P ease fo ow product abe instructions)

■Organic or conventiona fie ds

■Where uniform app ication of irrigation water is desired