TFP510

Page 8 of 10

Absence of the outer piece of an es-

cutcheon, which is used to cover a

clearance hole, can delay the time to

sprinkler operation in a re situation.

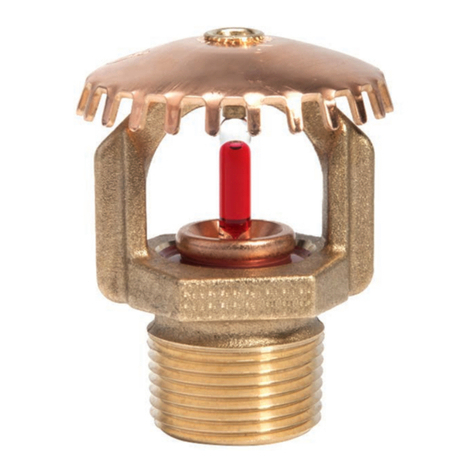

A Vent Hole is provided in the Bulb

Seat (Ref. Figures 1 and 2) to indicate

if the Dry-Type Sprinkler is remaining

dry. Evidence of leakage from the Vent

Hole indicates potential leakage past

the Inlet seal and the need to remove

the sprinkler to determine the cause of

leakage (e.g., an improper installation

or an ice plug). Close the re protec-

tion system control valve and drain the

system before removing the sprinkler.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro

-

sion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers before, during, and

after installation. Sprinklers damaged

by dropping, striking, wrench twist/

slippage, or the like, must be replaced.

Also, replace any sprinkler that has a

cracked bulb or that has lost liquid from

its bulb. (Ref. Installation Section.)

The owner is responsible for the in-

spection, testing, and maintenance of

their re protection system and devices

in compliance with this document, as

well as with the applicable standards of

the National Fire Protection Association

(e.g., NFPA 25), in addition to the stan-

dards of any other authorities having

jurisdiction. Contact the installing con-

tractor or product manufacturer with

any questions.

Automatic sprinkler systems are recom-

mended to be inspected, tested, and

maintained by a qualied Inspection

Service in accordance with local re-

quirements and/or national codes.

Limited

Warranty

For warranty terms and conditions,

visit www.tyco-re.com.

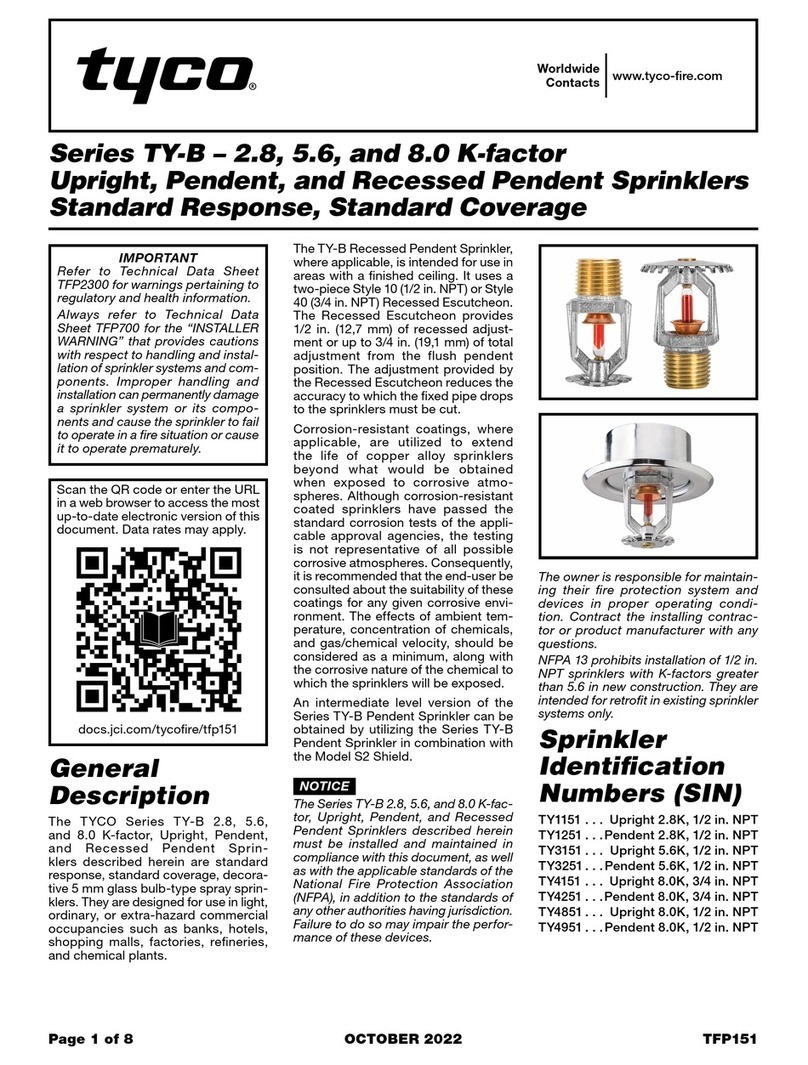

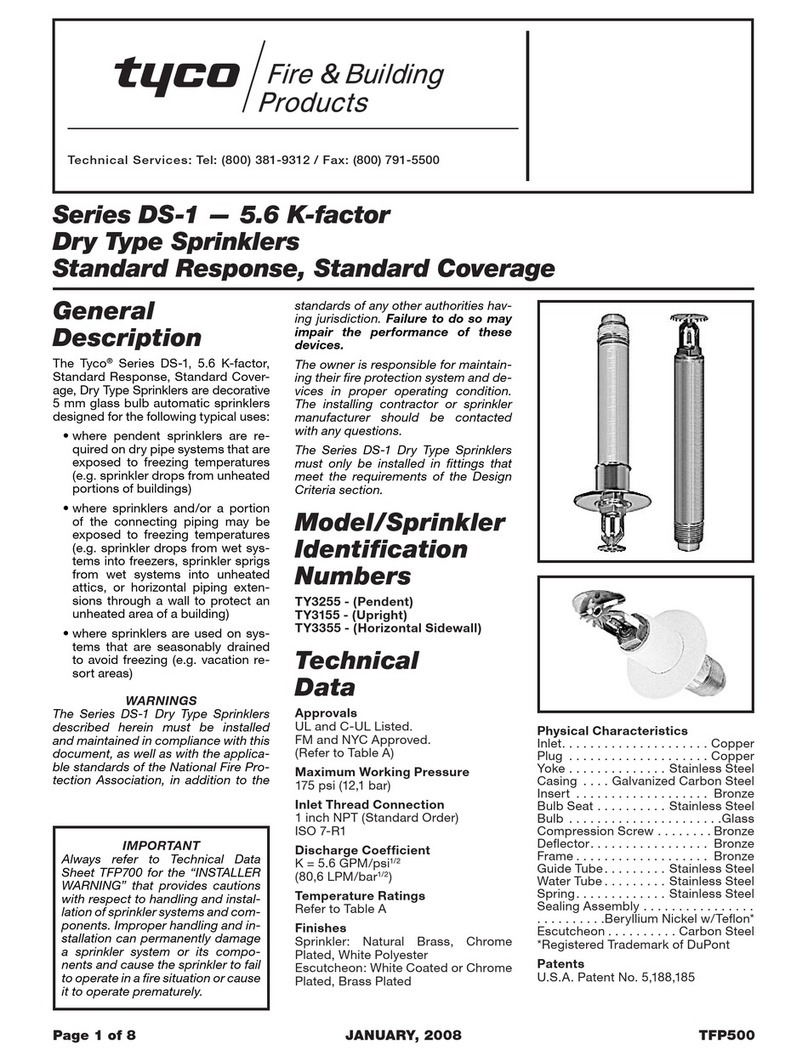

Step 1. Install pendent sprinklers only

in the pendent position, and install up-

right sprinklers only in the upright posi-

tion. The deector of a pendent or up-

right sprinkler must be parallel to the

ceiling.

Install horizontal sidewall sprinklers in

the horizontal position with their cen-

terline of waterway perpendicular to

the back wall and parallel to the ceil-

ing. Ensure the word “TOP” on the De-

ector faces the ceiling.

Step 2. With a non-hardening pipe-

thread sealant such as TEFLON tape

applied to the Inlet threads, hand-tight-

en the sprinkler into the sprinkler tting.

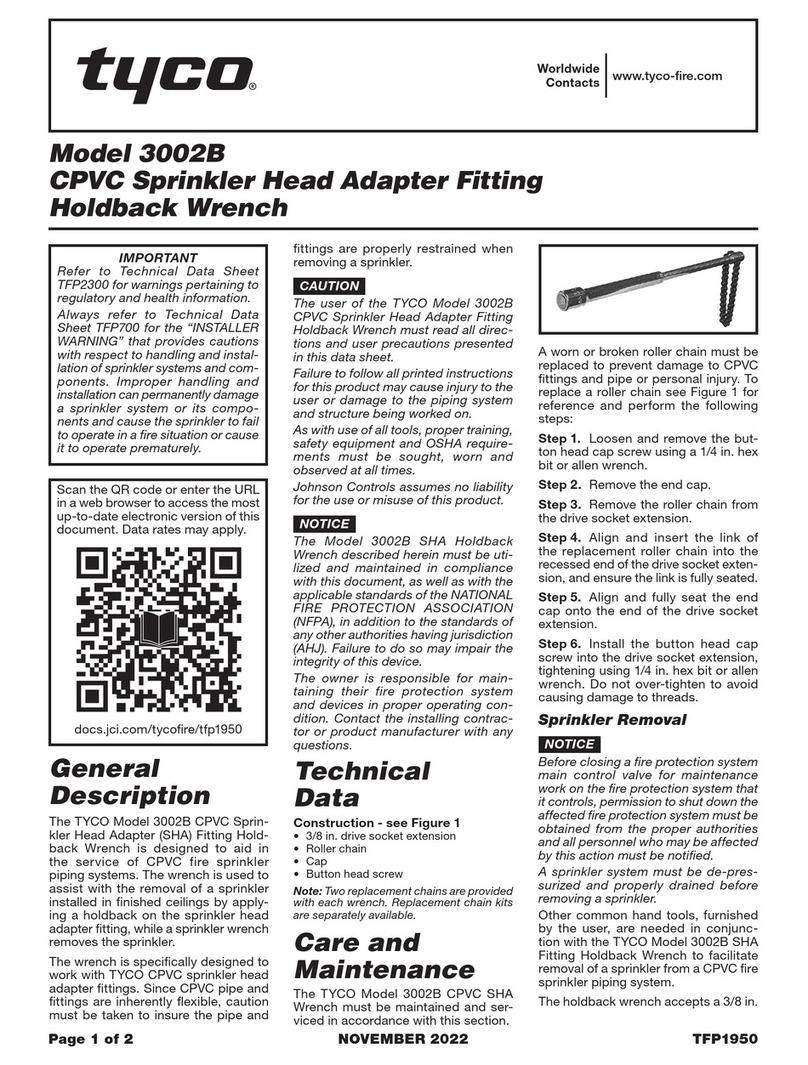

Step 3. Wrench-tighten the sprinkler

using either:

•

a pipe wrench on the Inlet Band or the

Casing (Ref. Figures 1 and 2)

•

the W-Type 7 Sprinkler Wrench on the

Wrench Flat (Ref. Figure 16)

Apply the Wrench Recess of the

W-Type 7 Sprinkler Wrench to the

Wrench Flat.

Note: If sprinkler removal becomes

necessary, remove the sprinkler us-

ing the same wrenching method not-

ed above. Sprinkler removal is easier

when a non-hardening sealant was

used and torque guidelines were fol-

lowed. After removal, inspect the sprin-

kler for damage.

Step 4. After installing the ceiling or

wall and applying a ceiling nish, slide

on the outer piece of the escutcheon

until it comes in contact with the ceil-

ing or wall. Do not lift the ceiling panel

out of its normal position.

When using the Deep Escutcheon,

hold the outer piece in contact with

the mounting surface (ceiling or wall).

Then rotate the inner piece approxi-

mately 1/4 turn with respect to the out-

er piece, to hold the Deep Escutcheon

rmly together.

Care and

Maintenance

The TYCO Series DS-1 Dry-Type

Sprinklers, 5.6K Pendent, Upright, and

Horizontal Sidewall, Quick Response (3

mm bulb) and Standard Coverage must

be maintained and serviced in accor-

dance with this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system that

it controls, obtain permission to shut

down the affected re protection sys-

tems from the proper authorities and

notify all personnel who may be affect-

ed by this action.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indicate

the full product name and Part Number

(P/N).

DS-1 Dry-Type Sprinklers

When ordering TYCO Series DS-1

Dry-Type Sprinklers, 5.6K Pendent,

Upright, and Horizontal Sidewall, Quick

Response (3 mm bulb) and Standard

Coverage, specify the following

information:

• SIN:

Pendent – TY3935 or TY3235

Sidewall – TY3735 or TY3335

Upright – TY3135

• 5.6 K-factor

• Deector Style:

Upright, Pendent, or Horizontal Sidewall

•

Quick Response, Standard Coverage,

Dry-Type Sprinkler

• Order Length:

Dry-Type Sprinklers are furnished based

upon Order Length as measured per

Figures 3 through 10. After taking the

measurement, round it to the nearest

1/4 inch increment.

• Inlet Connections:

3/4 Inch NPT, 1 Inch NPT, or ISO 7-R 1

• Temperature Rating

• Sprinkler Finish

•

Escutcheon Style and Finish, as

applicable

• Part Number (P/N) from Table D

The Upright Sprinkler without an

Escutcheon (TY3135) is available in

1 Inch NPT only.

Part Numbers are for 3/4 inch and

1 inch NPT standard order sprin-

klers. Orders for all other sprinkler

assemblies must be accompanied

by a complete description. Refer to

the Price List for a complete listing of

Part Numbers.

Sprinkler Wrench

Specify: W-Type 7 Sprinkler Wrench,

P/N 56-850-4-001

Sprinkler Boot

Specify: Model DSB-2 Dry Sprinkler

Boot, P/N 63-000-0-002

This Part Number includes one (1)

Boot, two (2) Strap Ties, and 1/3 oz. of

Adhesive (a sufcient quantity for in-

stalling one boot).