i

Rev. 9-09-16 Part #C-00084

www.NabcoEntrances.com Magnum 4A Control Wiring and Adjustment Manual

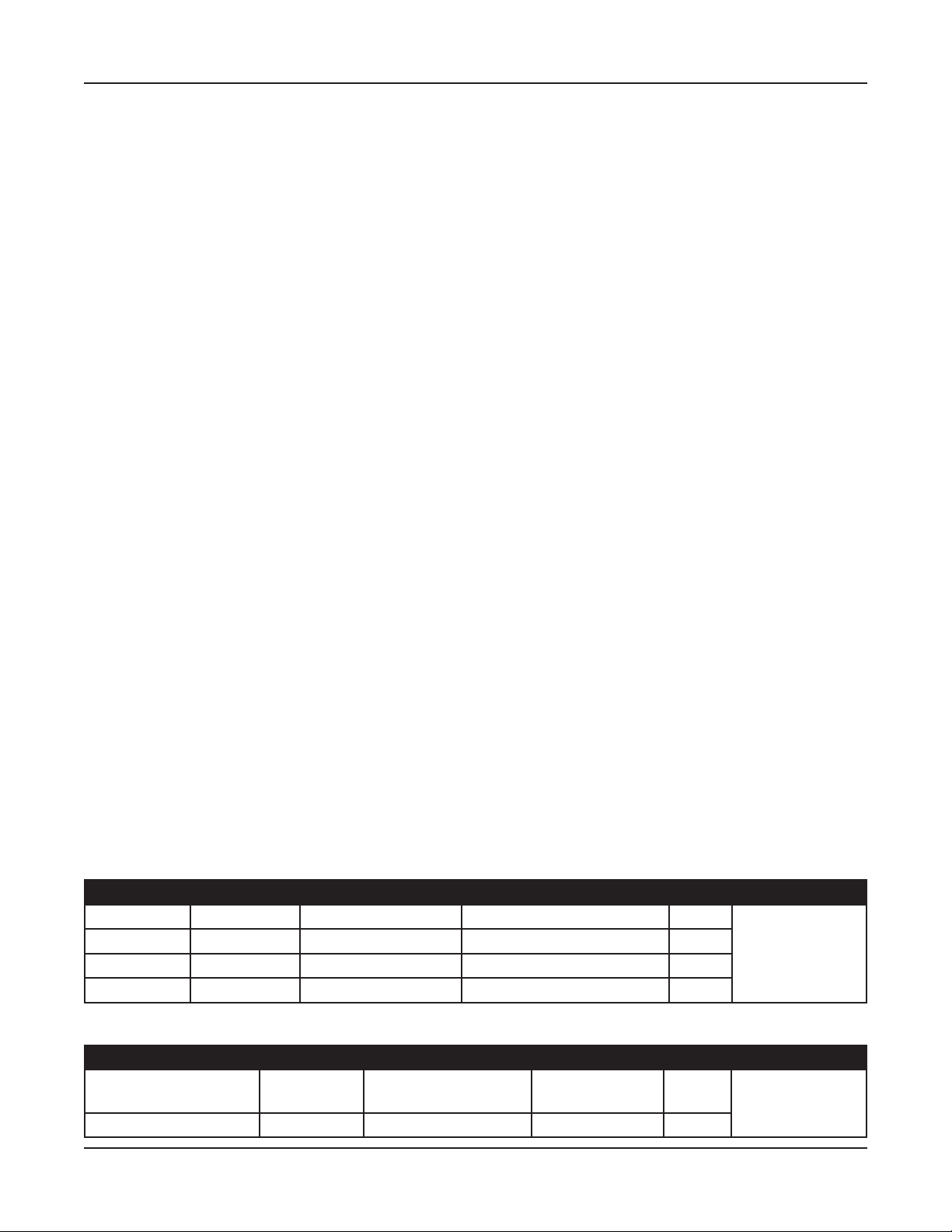

Table of Contents

Warning Labels .................................................................... ii

General Safety Recommendaons ....................................................iii

.......................................................

Secon 1a. To the Installer ...............................................................1-4

Secon 1b. Objecve ...................................................................1-4

............................................

Secon 2a. Features:....................................................................2-5

Secon 2b. Electrical Specicaons........................................................2-5

Secon 2c. Output Power Guidelines ......................................................2-6

..............................

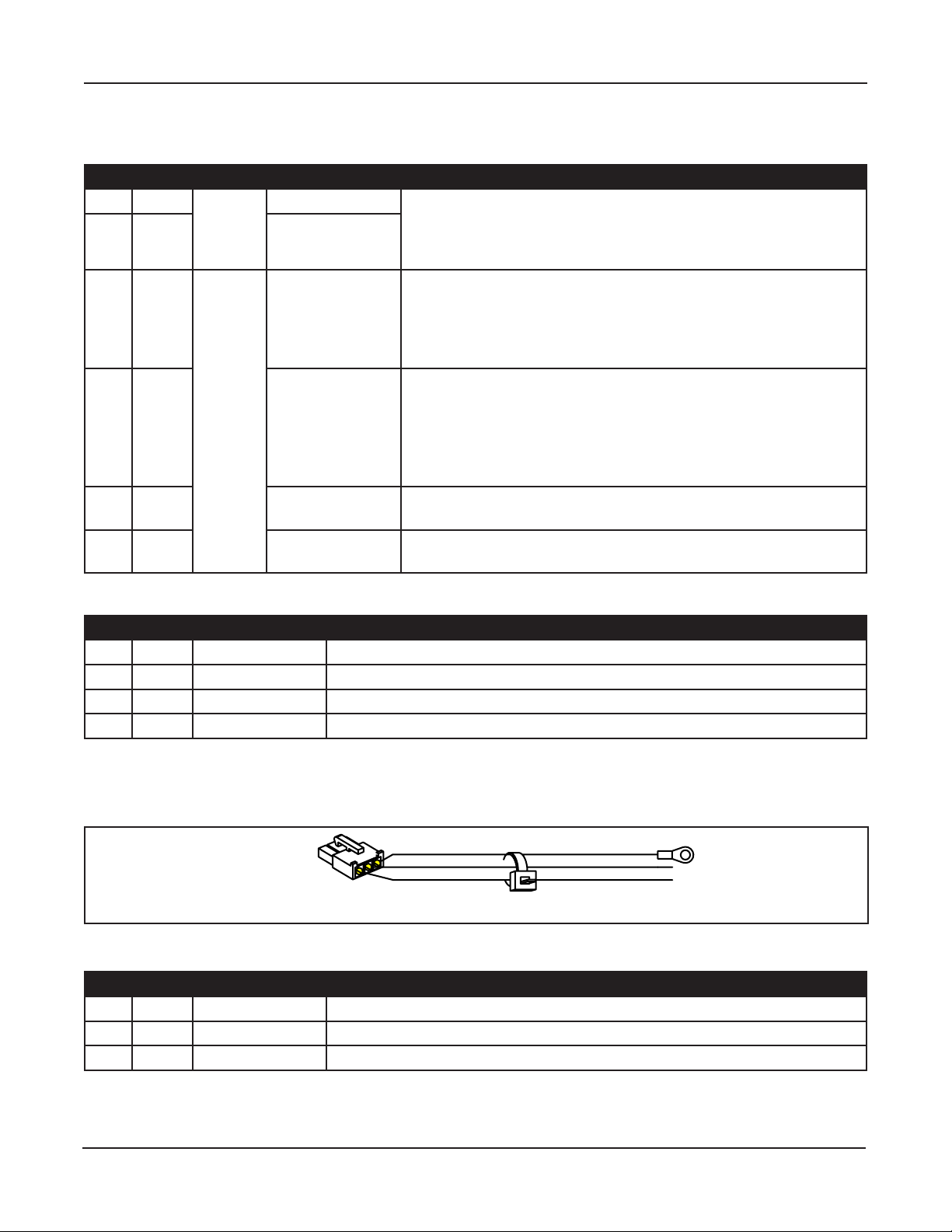

Secon 3a. Main Harness ................................................................3-7

Secon 3b. Power Harness ...............................................................3-8

Secon 3c. Motor Harness (300/400/500) ..................................................3-9

Secon 3d. Motor Harness (710/8310/8710)................................................3-9

Secon 3e. Fuses.......................................................................3-9

.............................

Secon 4a. Swing Door Posions.........................................................4-10

Secon 4b. Adjustments................................................................4-10

Secon 4c. Status LEDs .................................................................4-14

.........................

....................................

Secon 6a. Panic Breakout Latch/Switch (Open Loop Connuous Safety Circuit)..................6-16

Secon 6b. Panic Breakout Latch/Switch (Closed Loop Connuous Safety Circuit).................6-17

...............................

Secon 7a. GT-300-400-500 Single Door...................................................7-19

Secon 7b. GT-300-400-500 (Simultaneous Pair) ............................................7-20

Secon 7c. GT-300-400-500 (Simultaneous Pair w/One Magnum 4A Control) ....................7-21

Secon 7d. GT-710-8310-8710 Single Door ................................................7-22

Secon 7e. GT-710-8310-8710 (Simultaneous Pair)..........................................7-23

Secon 7f. GT-710-8310-8710 (Simultaneous Pair w/One Magnum 4A Control) ..................7-24

Secon 7g. GT-1400 Single Fold with One Magnum 4A Control ................................7-25

Secon 7h. GT-1400 Bi-Fold with Two Magnum 4A Controls ..................................7-26

Secon 7i. GT-1400 Bi-Fold with One Magnum 4A Control ....................................7-27

...........................

Secon 8a. Transformer Installaon and Wiring for 240 Volts .................................8-28

........................................