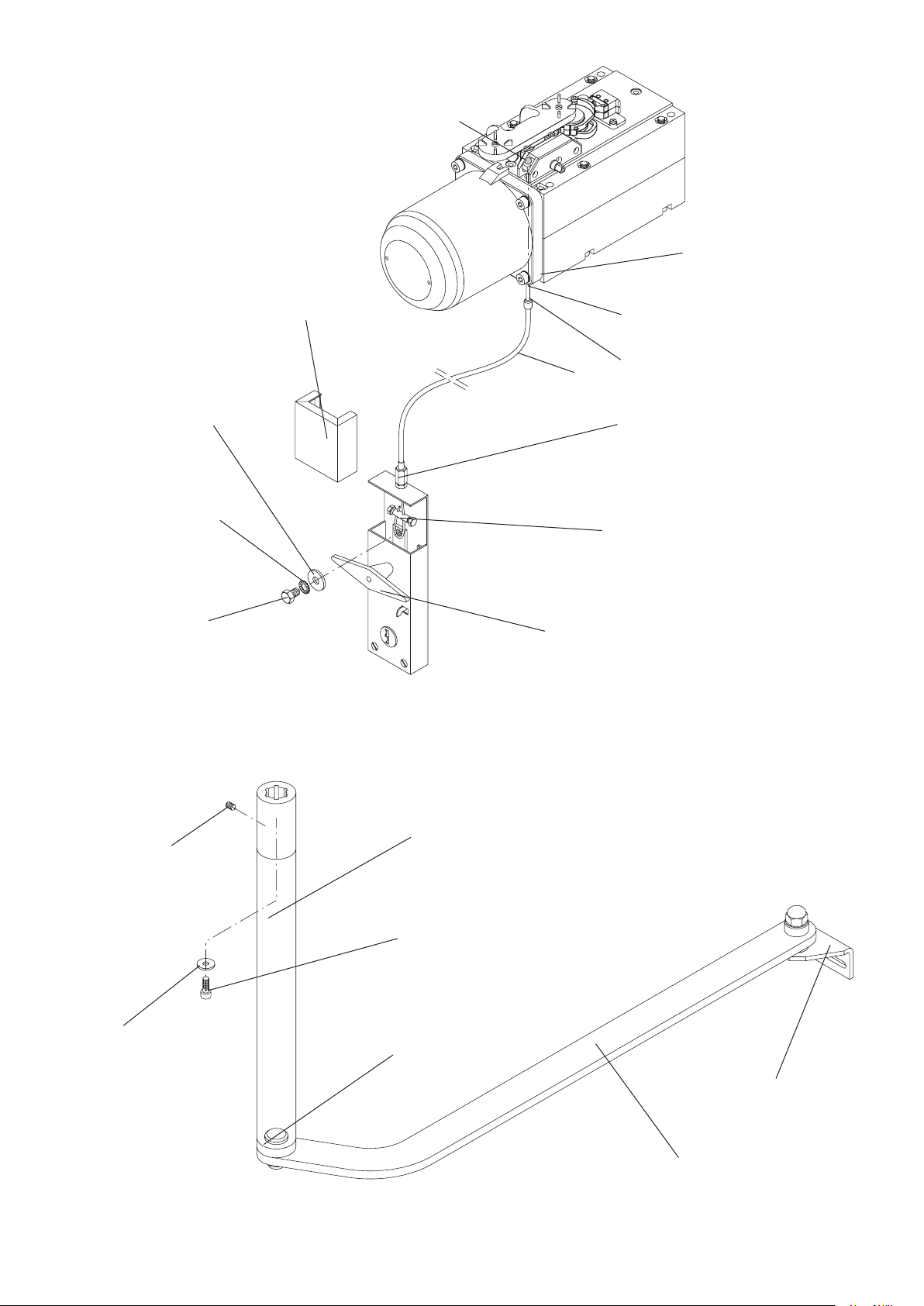

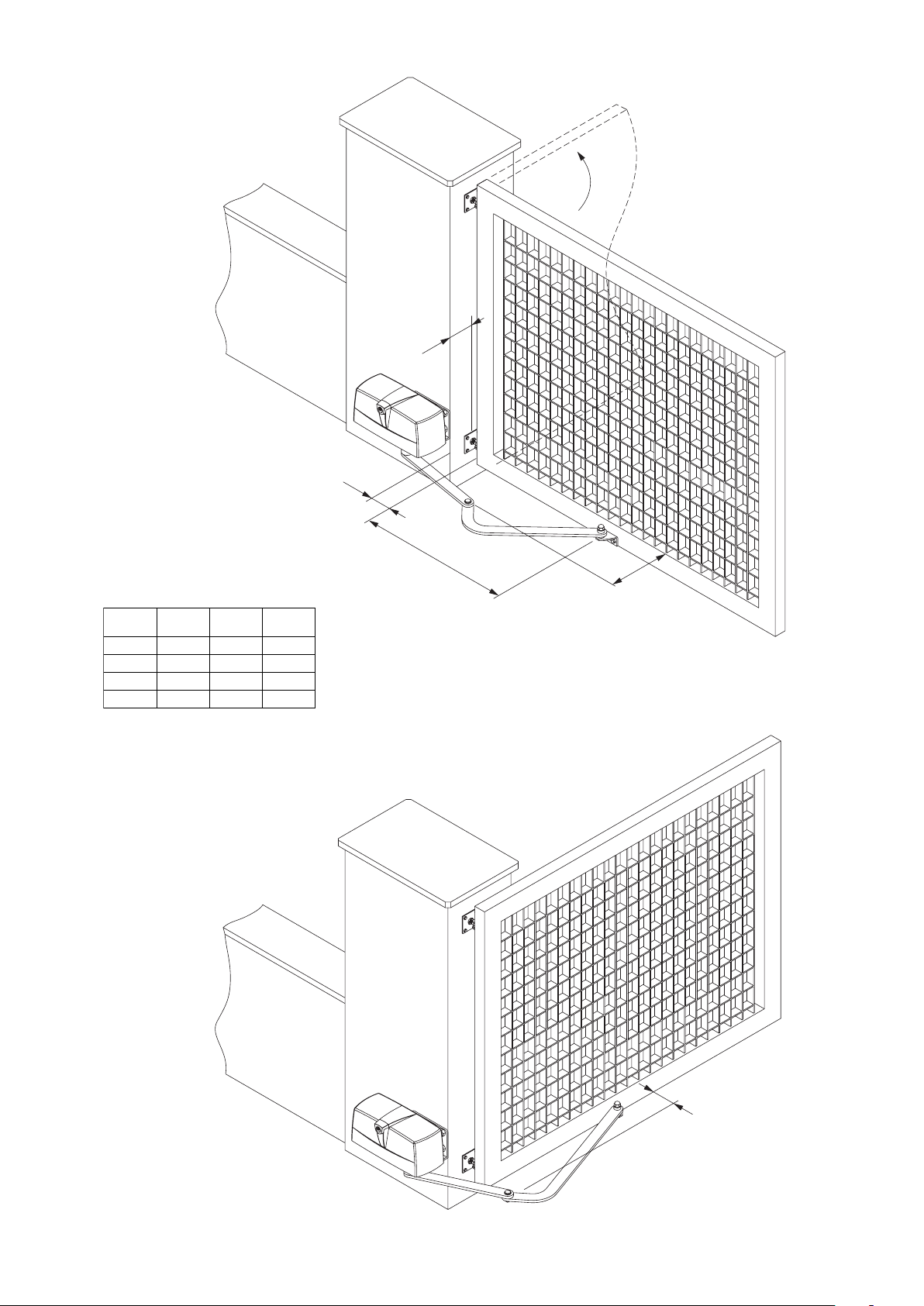

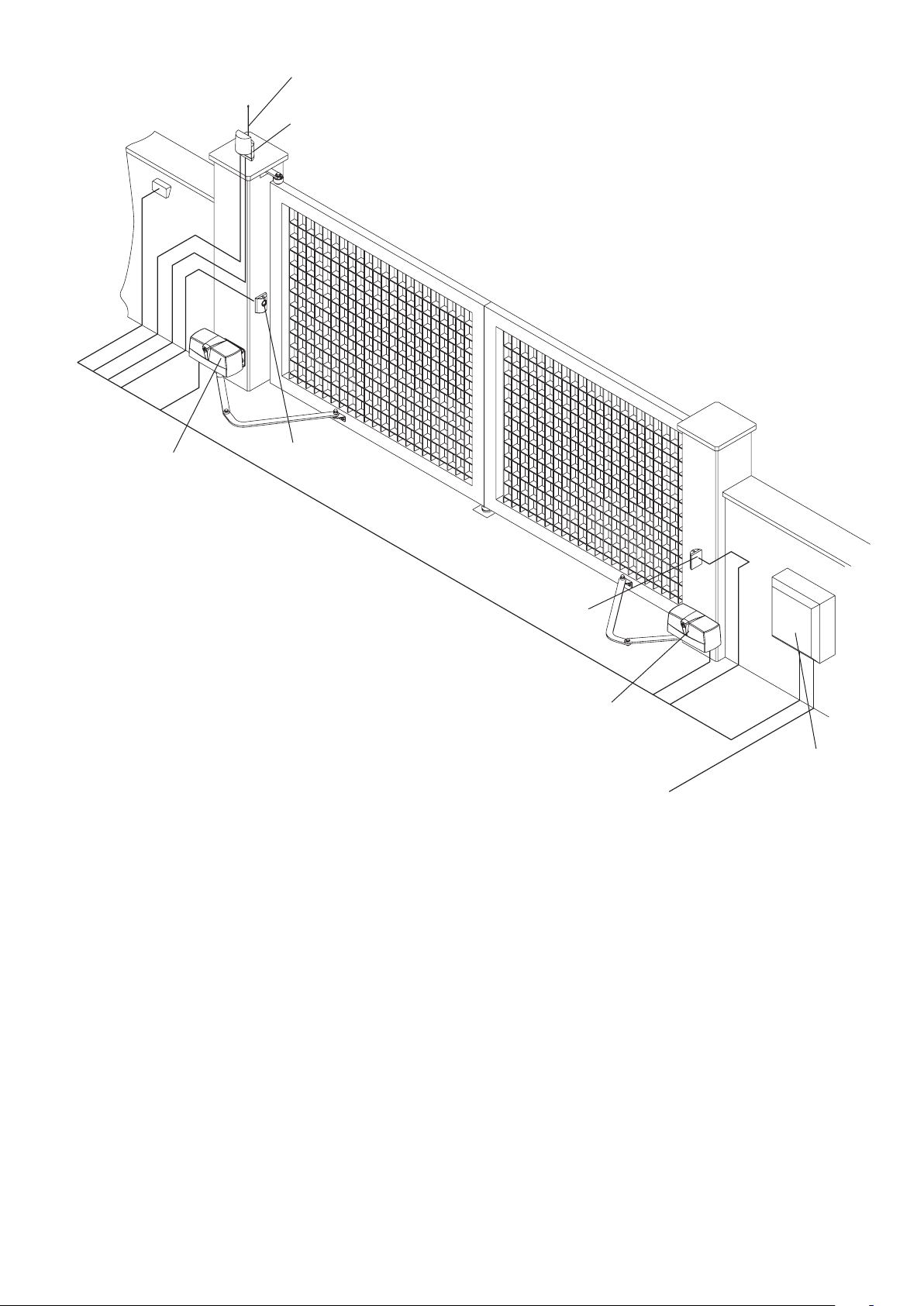

13

Warning•Before installation, carefully read the instructions hereunder.•It is strictly forbidden to use the item PREMIER for applications other than the intended uses described inthese instructions.•Instruct the user on how to use the system.IntroductionThank you for choosing our PREMIER ratiomotor. All items in the wide Benincà production range are the result of twenty-years’ experience in the automatism sector and of continuous research for new materials and advanced technologies. We are, therefore, in the position to offer higly reliable products that due to their power, effectiveness and useful life, fully satisfy the nal user’s requirements.All our products are manufactured to the existing standard and are covered by warranty. Possible injury to people or accidents caused by defects in construction are covered by a civil liability policy drawn up with one of the major insurance companies.General notesFor a good operation of the automatic system the door to be automated must feature the following character-istics:•Rugged and stiff door leaves.•Efcient hinges.•The door leaves should be moved by hand without any friction for the entire stroke.•The doors should be complete with a catch in the closing phase.In the negative, replace the faulty parts. Reliability and safety of the automatic system depend on the gatestructure.General featuresThis automatism has been designed to automatize doors, the dimensions of which do not allow to use tra-ditional actuators.It is equipped with an articulated arm and with a limit switch, (PREMIER). The operations are smooth and noi-seless. It is easy to be assembled and, thanks to its pleasant design, it meets the most demanding needs.The emergency block is simple and safe thanks to the lever with personalised key.ConnectionsPR.45E/PR.45EL / PR.45ER:Brown Motor phase and capacitorGrey or Light blue CommonBlack Motor phase and capacitorYellow/Green Earth - compulsory pursuant to regulations in forceThe limit switch contacts are connected in series to the two motor phases. If, after an opening control, the motor starts the closing movement, it is sufcient to reverse the brown wire with the black one in the control unit.PR.45E24:Red Motor +Black Motor -Carry out the limit switch connections to the control unit.If, after an opening control, the motor starts the closing movement, it is sufcient to reverse the red wire with the black one in the control unit.As regards the torque adjustments and the operating modes, please read instructions given in the control unit manual.To adjust the limit switches (Fig. 3)The PR.45E unit is equipped with built-in limit switches for both opening and closing phases. Proceed as follows:•Release the actuator (see paragraph “Release by hand”)•Remove the cover M from the release lever L.•Loosen the screw V1 and remove the release lever L.•Loosen the screws V2 and remove the cover.