5 TY-GC62-010A Rev.2

Table of Contents

For Proper and Safe Use..........................................................2

Definition of Safety Terms ...............................................................................2

Description of Graphic Symbols.....................................................................2

Precautions for Handling Product..................................................................3

1. Preface ...................................................................................6

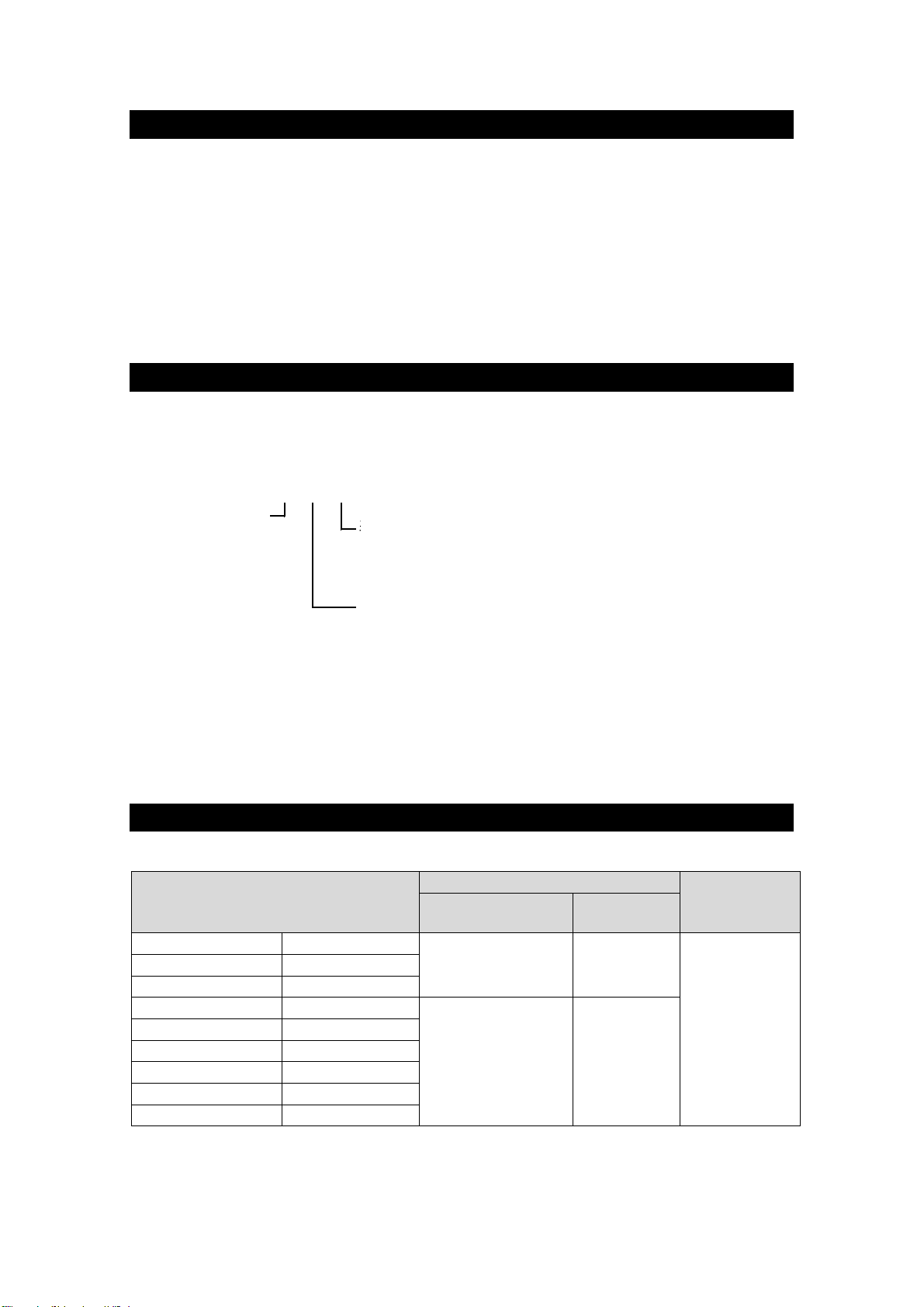

2. Model Number Structure......................................................6

3. Specifications........................................................................6

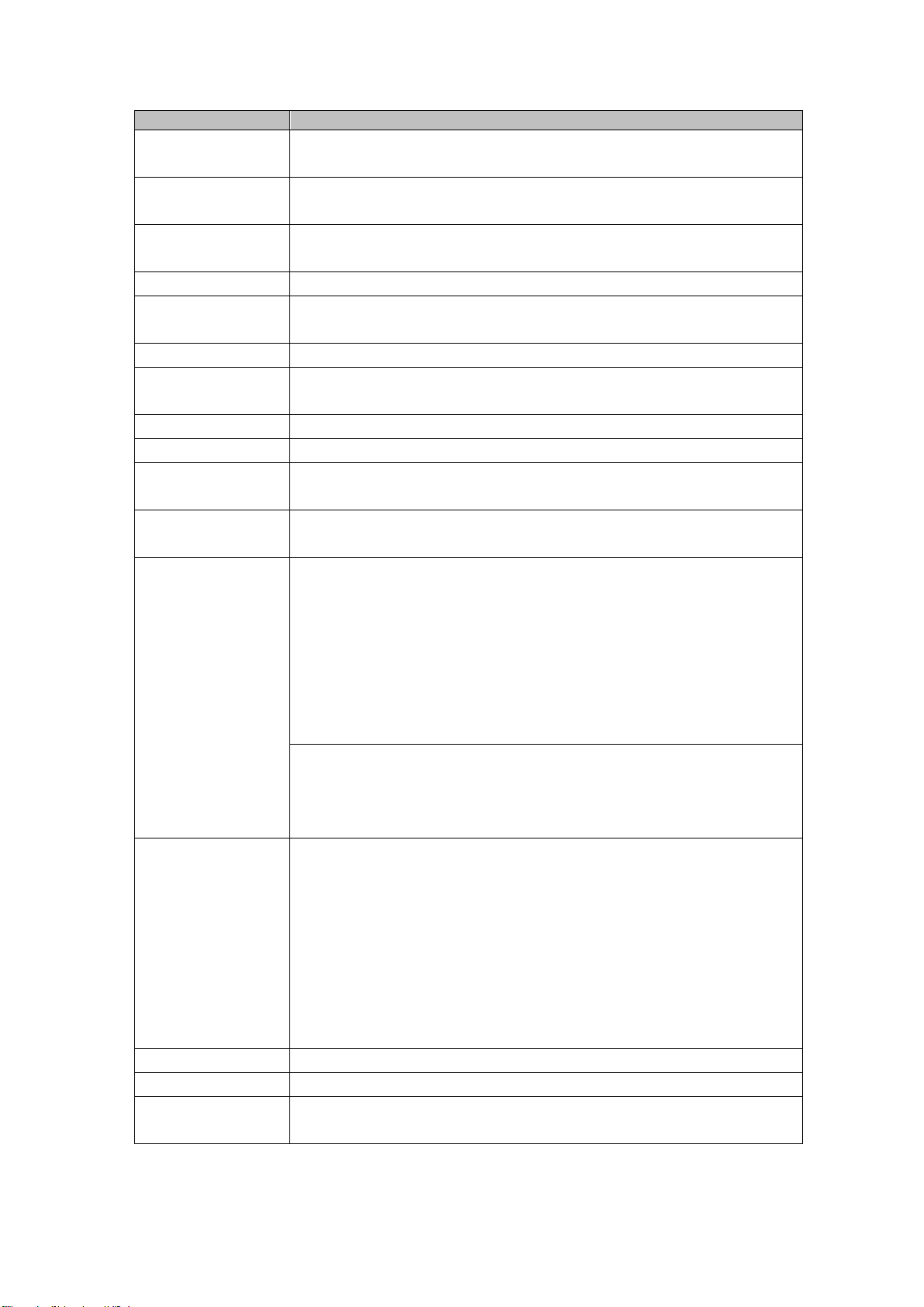

3.1 Product Specifications...............................................................................6

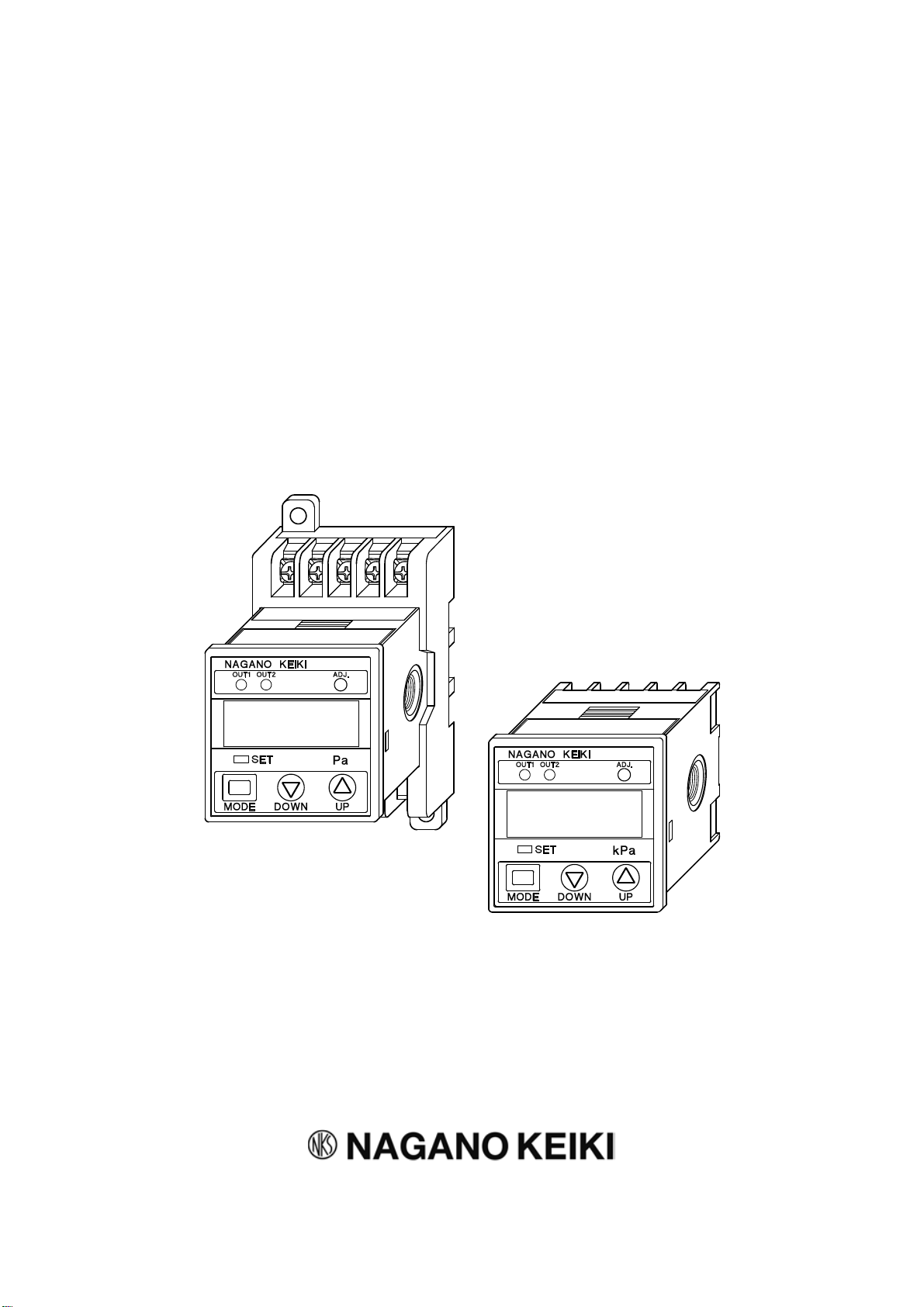

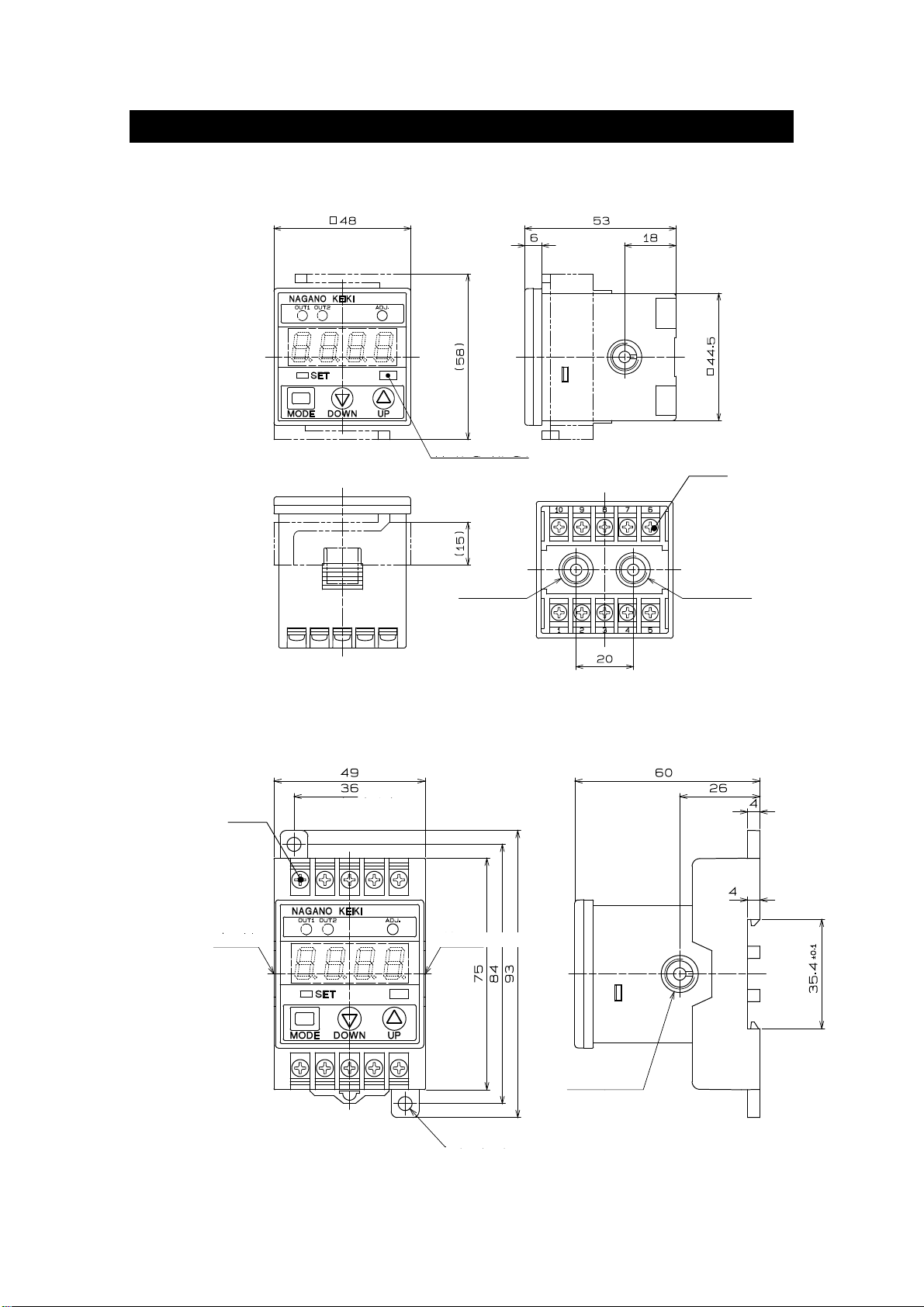

4. Dimensions............................................................................9

4.1 Outline Drawing of Pressure Gauge......................................................... 9

4.2 Wall Mount (DIN railing is attachable)...................................................... 9

5. Installation and removal.....................................................10

5.1 Piping.........................................................................................................10

6. Wiring and Connection.......................................................11

6.1 Wiring......................................................................................................... 11

6.2 Internal Format..........................................................................................12

6.3 Contact Protection....................................................................................12

7. Usage and Settings.............................................................13

7.1 How to Switch to Each Mode...................................................................13

7.2 Function Setting Mode.............................................................................15

7.3 Comparator Setting Mode........................................................................18

7.4 Comparator Operation.............................................................................20

7.5 Other Functions........................................................................................21

8. Measures against Noise.....................................................23

8.1 Effects of Noise.........................................................................................23

9. Storage.................................................................................23

9.1 Precautions for Storage...........................................................................23

10. Maintenance ......................................................................24

10.1 Periodic Inspection ................................................................................24

11. Product Warranty and Export Administration Regulations

....24

11.1 Product Warranty....................................................................................24

11.2 Export Administration Regulations......................................................24

12. Others.................................................................................24