CONTENTS

1.

2.

bd

VW.

GOTOF

AD

ss

5.06%,

aie

Shales

cele

race saya

laeyiat

bumps:

by

inca

BoB

acate

Kekied

Gea

yare

Javaliphere

©

elepdl

Guacatte

@ists

Sawicwteee

2

Wo 1,

Control

Functions

........

2

Va.

:2,

Voltage

Selector..........

3

1,

3.

Functions

..........-.-5

3

1.

4,

How

To

Read

Signals

5

1.°¢5.

Semiconductor

Switch

5

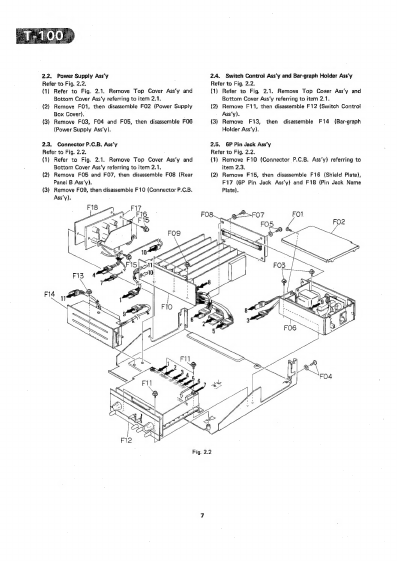

Removal

Procedures

..

1.2200.

eee

ee

cee

reer

cece

eee

eee

ee

eee

tee

tent

eee

e

renee

6

2.

12

Top

Cover

Ass’y,

Bottom

Cover

Ass’y

and

Synthesis

Mechanism

Ass’y

with

Power

Supply

Ass’y...

6

2.

2.

Power

SUPPIV

ASS

Vi?

5.22850

hissed

LORS

hs

ad

tate

See

teig

oe

Wit

eset

Ss

ent

Eee

Bee

Be

dk

ede

7

2

3.

Connector

P.C.B.

Ass’y

«0.

ee

ee

eee

eee

7

2.

4.

Switch

Control

Ass’y

and

Bar-graph

Holder

Ass’y

. .

7

2.

5.

GP

Pin

Jack

Ass’y

2...

eee

cee

eee

7

2

6.

Switch

P.C.B.

Ass’y

and

Votume

P.C.B.

Ass'y

2...

cee

cee

ee

ete

eee

en

neee

8

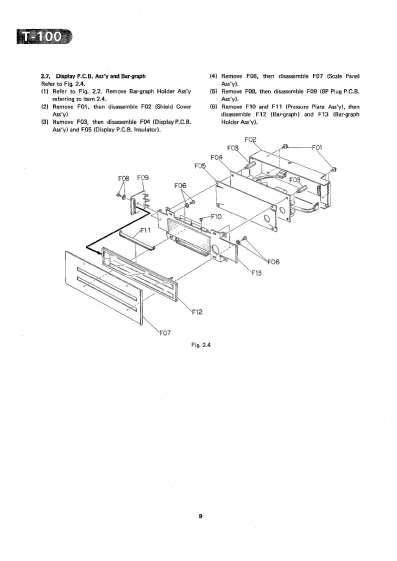

2

7.

Display

P.C.B.

Ass’y

and

Bar-graph

2...

ce

cee

eee

ett

eee

et

neee

9

2

8,

Power

Supply

P.C.B.

Ass‘y

and

Power

Transformer

.

10

2

9.

Rear

Panel

A

Ass'y,

Power

Switch

and

AC

Inlet...

10

Measurement

Instruments

..

20...

0000

v

eee eee

e

renee

10

Parts

Location

for

Electrical

Adjustment...............

11

44,

CUrrent

TY

Pe

accede

ee

See

eee

ee

ea

1

4.

2,

Previous

Type

........

2.

eee eee

eee

eens

11

Adjustment

and

Measurement

Instructions

..........-..,0000-

staat

12

5.

1.

Current

Type.............08

See

ODE

ae

tein

&

foe

Sab

Sande

diby

skater

ere

iececaueuhw

sara

rapsress

abate

cates

12

5,

2,

Previous

Type»...

eee

ee

eee

eee

eee

15

Mounting

Diagrams,

Circuit

Diagrams

and

Parts

List

18

6.

1

IC

Block

Diagrams

18

6

2

Connector

P.C.B.

Ass’y

19

6

3.

Power

Supply

P.C.B.

Ass’y

21

6

4,

Wow

&

Flutter

P.C.B.

Ass’y

..

23

6,

5,

Switch

P.CB.Ass’y..

ce

eee

cette

ee

ete

nent

cette

emcee

tense

tee

tn

nee

25

6.

6

Oscillator

'P.C:B.:Ass’yoss.i.3

eccd

ioe

de

ey

eee

bie

ea

ene

eee

ee

ne

25

6.

7.

Absolute

Rectifier

P.C.B.

Ass’y

..

2.22.20

0.05

:

esa

eh

6.

8

Linear/Log.

Converter

P.C.B.

Ass’y

Bila

ghd

29

6

9.

Distortion

P.C.B.

Ass’y

1...

eee

eee

eee

Setiexionpe:

2Ot

B20Os”

“Noltitne

PiC.B

Ass!

y

se

asscz-es

seis

as ee

setcatee

ceraeetarsactes

Sie

re

eran

el

natin

Zoe

Se

halon

Se

nl

tne

Se ed

“awd

arated

33

6.

11.

IHF-A

WTD

Network

P.C.B.

Assy

35

€

12.

Display

P.C.B,

Ass’y

37

6

13.

Analog

Multiplier

P.C.B.

Ass’y

39

Mechanism

Ass’y

and

Parts

List...

2.2...

0.

cece

eee

eee

ee

eee

eee

41

as

OV

SV

MUESIS

A350

cea

wand

rated

cas

int

Diese

ei

Mees

ne

ar

eles

slsdeeted

hap

aoe

aces

Bb

anata

Nay

Mian

ore

Sara

Macavauehas

anlar

raneea

41

7. 2.

Synthesis

Mechanism

Ass’'y

{(AO1)

2...

ce

ce

eee

eee

eee

nee

eee

42

7

3.

Power

Supply

Ass‘y

(A02)

43

7

4.

Switch

Control

Ass’y

(B01)

45

7

5.

Bar-graph

Holder:Ass’y:

(BOQ)?

seg

2-5,

e-v

ecesce

womeeees

dasha

veteraereeraye

re

wos

oe

tebe

validy

dae

Ae

46

7.

6.

Connector

Ass’y

(B03)

47

Block

Diagram

.......,

48

Wiring

Diagram

........

49

Troubleshooting:

ca

teen

he

ie

a

eye

eee

ee

Baik

ea

ce

aresw

ddd

eased

da

febalra

te

1a

Ja

Ranaehareialayalniinadereoe

end

ae

lo

50

10.

1.

Notes

50

10.

2.

Troubleshooting

.

50

Specifications

53