3. Safety Precautions

7

During work with the forklift, appoint a work leader. The work leader should

give directions for work according to a work plan. If a work leader is not

appointed, risk of accident may increase, because of insufficient

association with surrounding work.

Modification of the forklift may deteriorate performance and safety of the

forklift.

If modification is required, please consult the manufacturer.

Do not attach any part to the forklift other than the accessories allowed by

the forklift manufacturer. Failure to observe this instruction may lower

stability and strength required for safety

When the forklift is left unused, remove the key from the key switch, and

keep it. If the key is left in the switch, an unauthorized person or a person

who has not been familiarized with operation of this forklift may operate

the forklift, resulting in an accident.

If the forklift is used in a fault or abnormal condition, it may result in

collision, cargo fall or forklift overturn accidents because the forklift cannot

be normally operated due to the fault. If a fault or abnormality is found with

the forklift, repair it immediately.

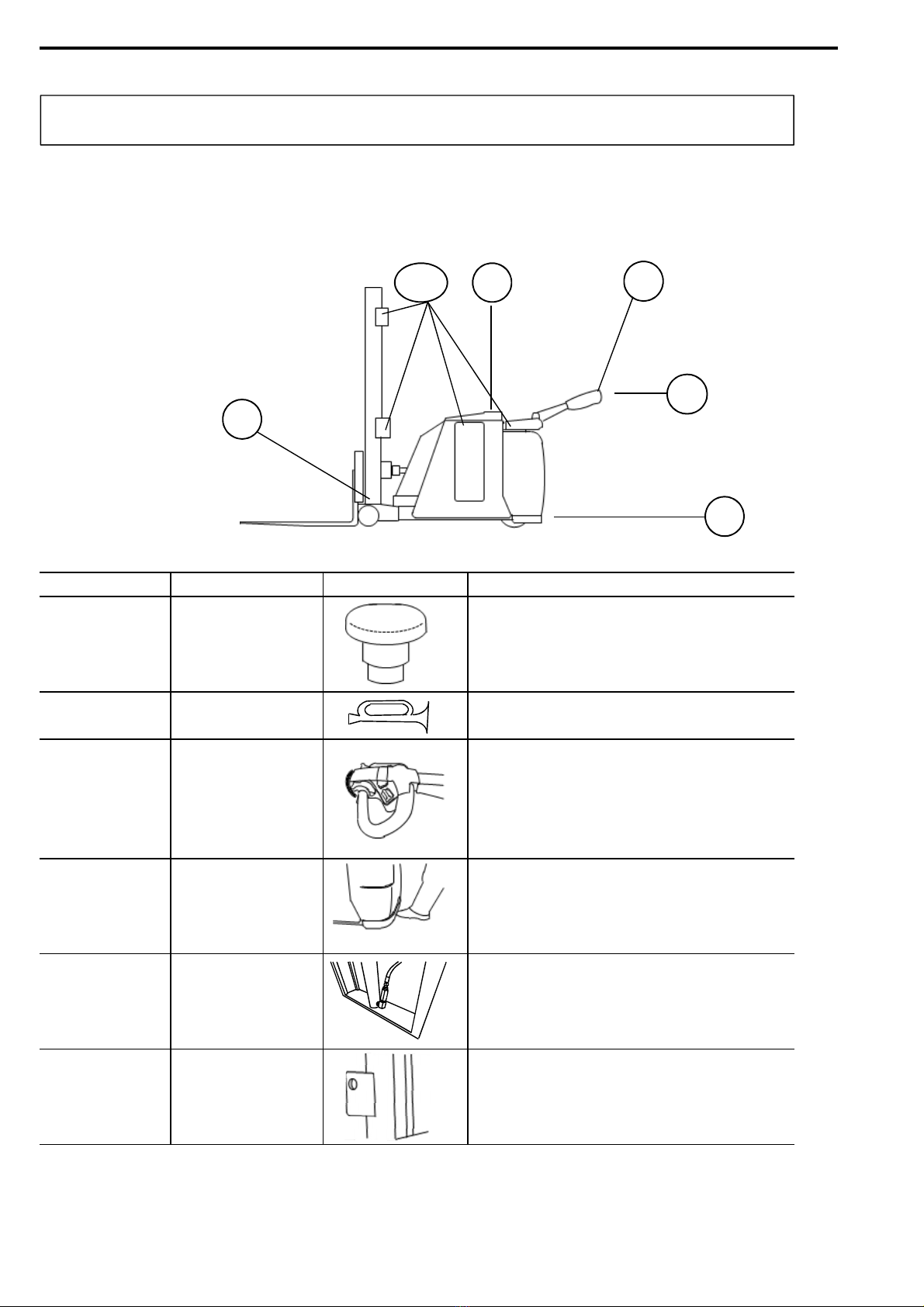

When lowering the fork from the traveling position to the operating

position, hold the fork, and lower it carefully. If you handle the fork roughly,

your hand may get pinched with the fork, resulting in injury such as bone

fracture and bruise.

WARNING

Appoint a work leader.

Remove the key when the forklift is left unused.

When restoring the fork from the traveling position, handle it

carefully.

Do not use a forklift in a fault condition.

Do not attempt to modify the forklift.

Do not attach any part other than the genuine accessories.

WARNING

WARNING

DANGER

DANGER

WARNING