1

Contents

1.The eneral Introduction..........................................................................................................................2

2.Proper usage................................................................................................................................................ 2

Modification............................................................................................................................................... 3

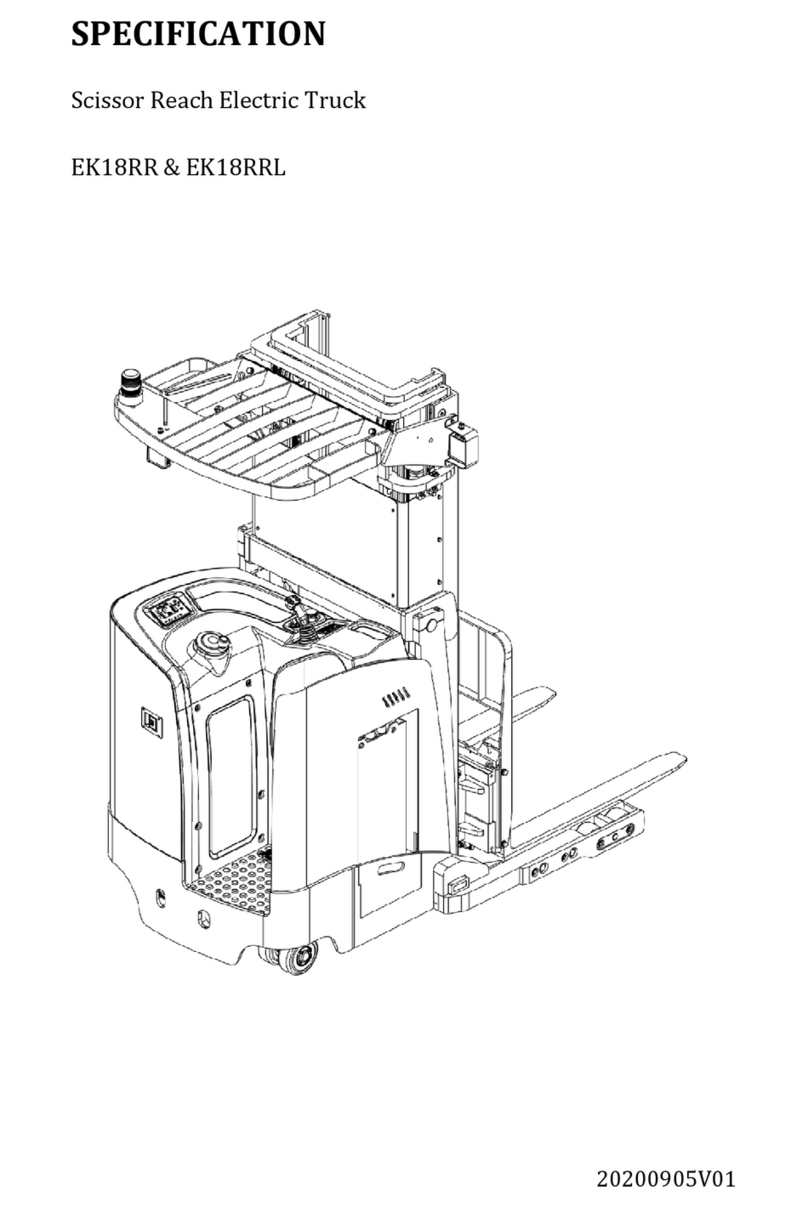

3.Introduction of the product...................................................................................................................... 3

3.1 Model Overview...................................................................................................................................4

3.2 Model.................................................................................................................................................... 4

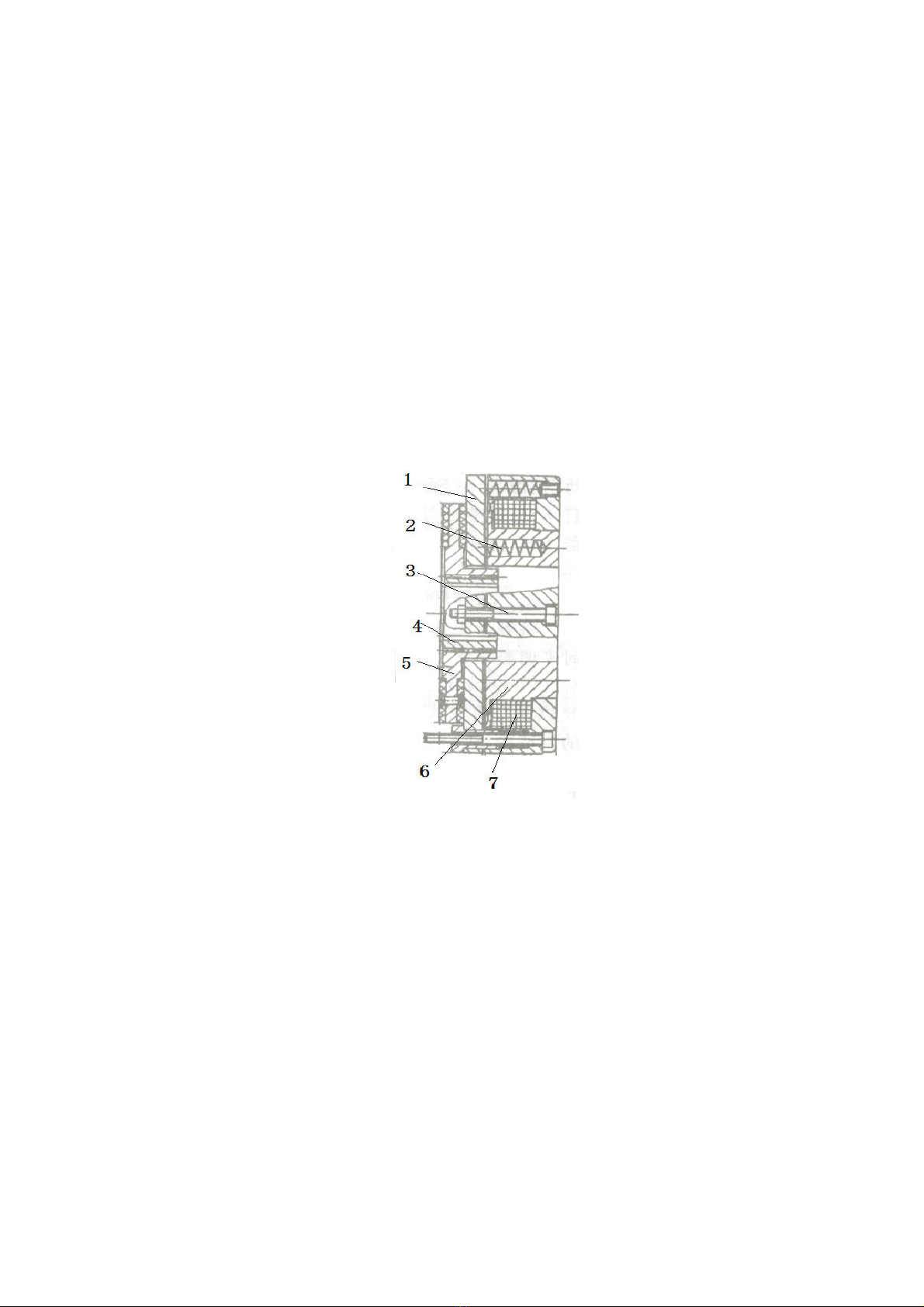

4.Operating principle.................................................................................................................................... 5

Operating mechanism diagram:.................................................................................................................. 6

5.Operating principle.................................................................................................................................... 6

5.1 Running system................................................................................................................................... 7

5.2 Steering system....................................................................................................................................7

5.3 Braking system.................................................................................................................................... 7

5.4 Operating System................................................................................................................................ 8

5.5 lectric System.....................................................................................................................................8

5.6 Hydraulic principle..............................................................................................................................9

6.Electrical schematic diagram....................................................................................................................9

7.Hydraulic Principle Diagram.................................................................................................................. 10

8.Operating instruction...............................................................................................................................11

8.1 Start, run and parking:...................................................................................................................... 11

8.2 The usage of emergency safety switch............................................................................................ 12

8.3 The usage of horn button.................................................................................................................. 12

8.4 Battery capacity indicator.................................................................................................................12

8.5 Handling stacking operation.............................................................................................................12

9.Maintenance...............................................................................................................................................13

9.1 Safety procedures for repair and maintenance.............................................................................. 13

9.2 Daily Maintenance............................................................................................................................. 14

9.3 Professional Maintenance Manual................................................................................................... 14

9.4 Maintenance, Recharging and Replacement of the accumulator.................................................. 16

10.Safety Precautions.................................................................................................................................. 19

10.1 general rules.................................................................................................................................... 19

10.2 Transportation and storage............................................................................................................19

10.3 Check before Using..........................................................................................................................20

10.4 Safe Operation................................................................................................................................. 20

11.Repair Manual......................................................................................................................................... 22

11.1 Malfunction analysis....................................................................................................................... 22

11.2 preparation work before repair.....................................................................................................22

11.3 check the oil content of hydraulic oil.............................................................................................23

11.4 preparation work before use after maintenance..........................................................................23