INTRODUCTION

We thank you for your purchase of NAOMOTO

Model HSP-440 All Steam Iron.

This Instruction Manual is a guide book for

correct use of this iron. Please read this booklet

carefully before using the iron to ensure its

longest possible life.

This iron features our own Condensate Return

System design and is named the “All Steam

Iron’ as it has no electric heater built-in.

We would like you to become familiar with the

outlined structure and functions of the iron so

that you can operate it correctly and efficiently

to your satisfaction.

NOTES

1. In order to ensure safe and prolonged use of

the iron, it is essential that it is used correctly

and that regular maintenance checks are

carried out. Before undertaking any operation

and maintenance work, please read this

manual carefully as well as other manuals of

related machinery such as ironing tables, etc.

that may be used in conjunction with the iron. If

the iron is defective in any way, please contact

the nearest Naomoto office or agent.

2. If the iron is resold or rented to a third party,

please ensure that this manual accompanies

the iron. If the manual is unavailable, ask us for

an extra copy.

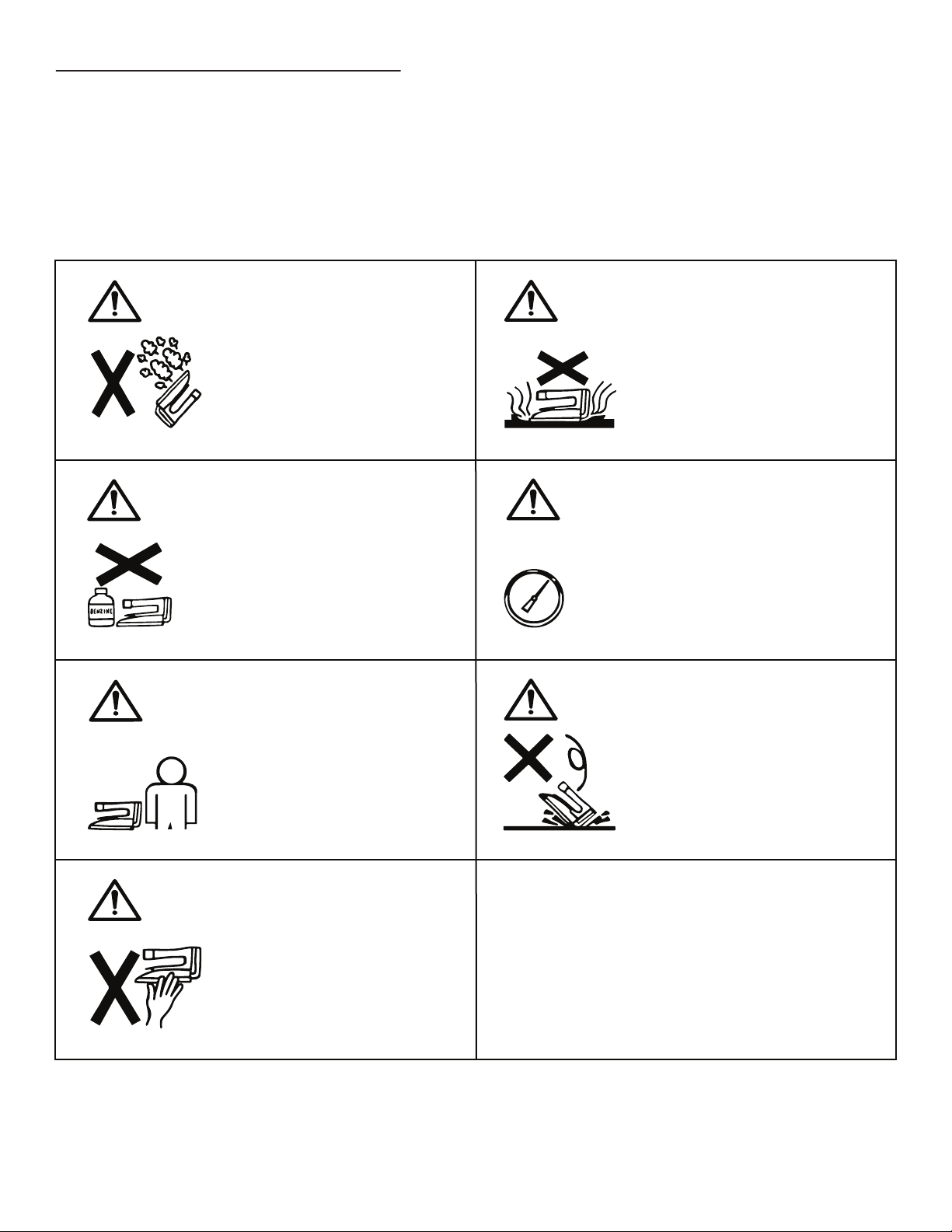

3. In this manual, those actions or conditions

that may cause a fatal accident and/or fire are

marked ”WARNING”, and those that may

cause a breakage and or malfunction of the iron

as well as damage to the fabrin or garment

being worked on are marked “CAUTION”.

4. We do not take any responsibility for injury or

damage arising as a result of the user’s

negligence of the instructions in this manual,

particularly those areas marked as “WARNING”

and “CAUTION”. Any such damage or injury is

not covered under the terms of the warranty.

5. Please note that, as a result of our ongoing

vigorous efforts to improve our products, some

specifications of the machine you have

purchased may slightly differ from those

mentioned in this manual.

CONTENTS

1. SPECIFICATIONS........................................1

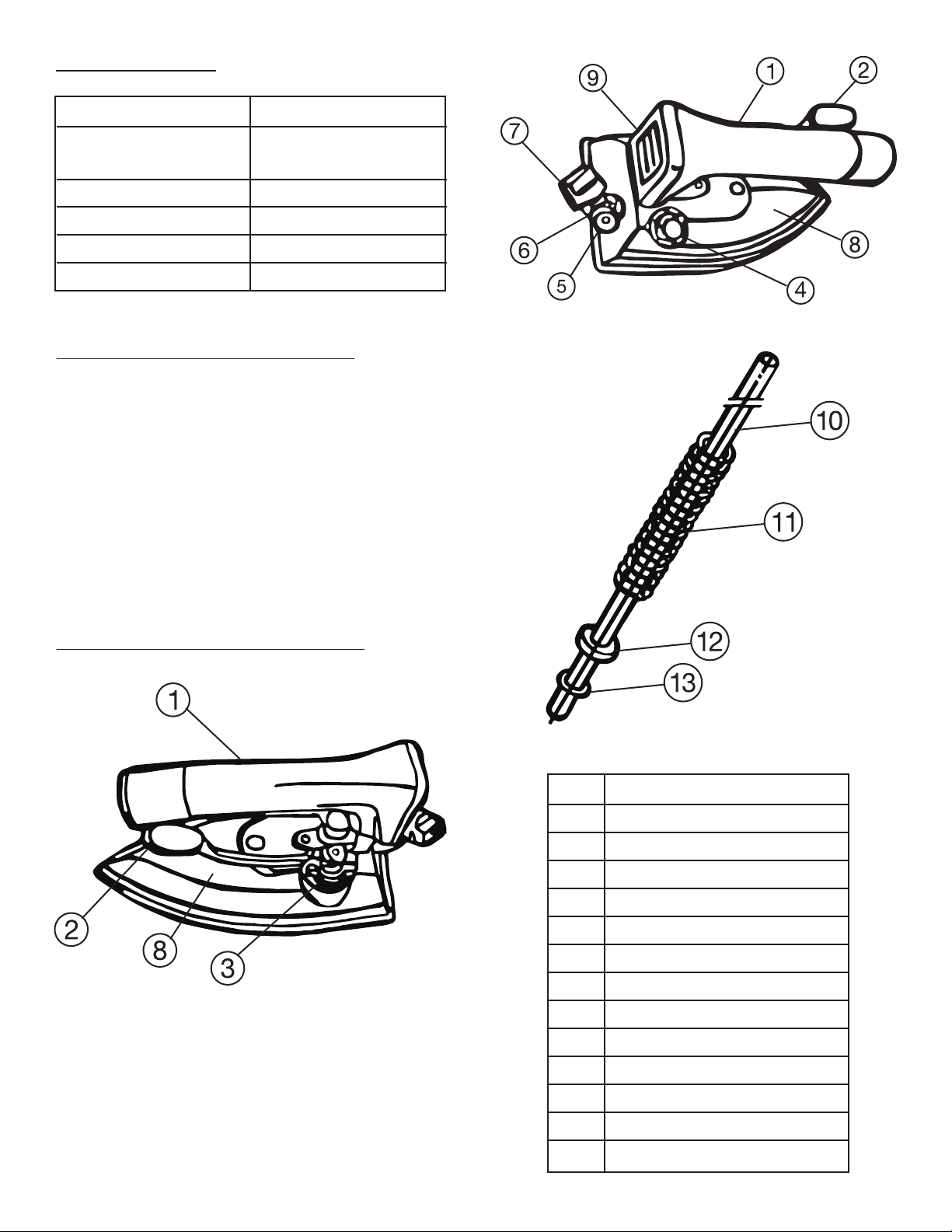

2. ATTACHMENTS & ACCESSORIES..............1

3. NAMES OF COMPONENT PARTS..............1

4. PRECAUTIONS BEFORE OPERATION........2

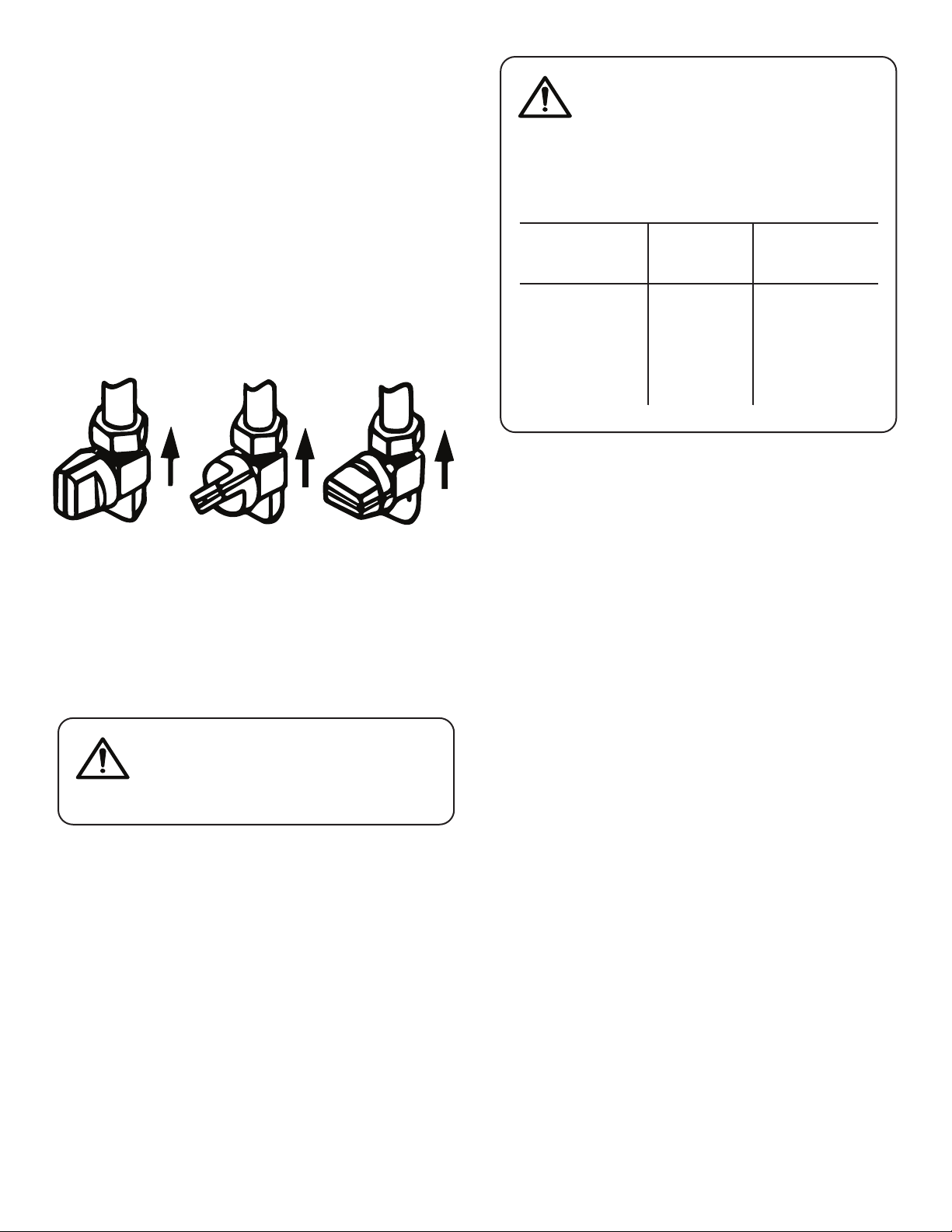

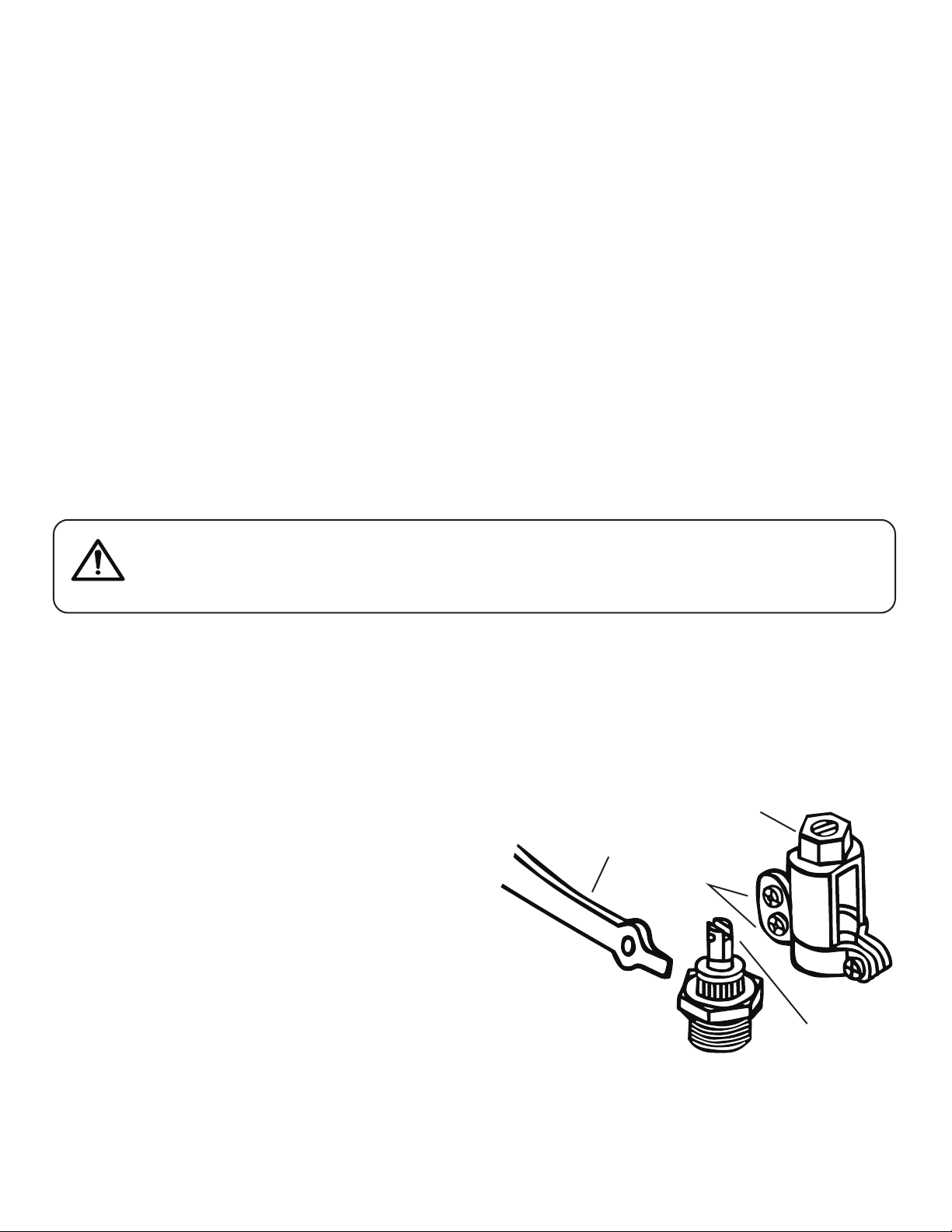

5. INSTALL & ASSEMBLE................................3

6. IRONING OPERATION.................................5

7. MAINTENANCE & CHECKING....................6