4

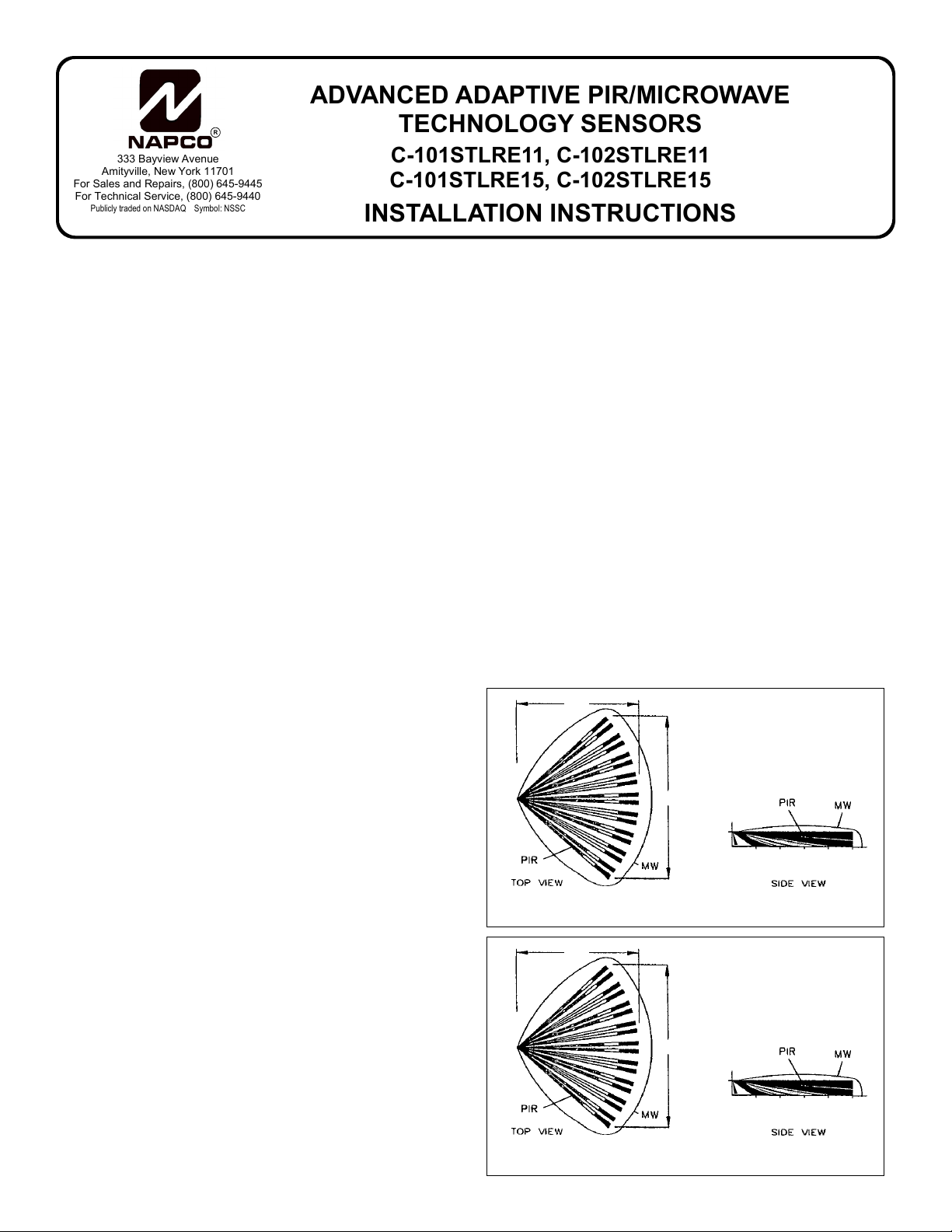

the LED begins to flash. Set the control for the desired range. To

prevent false Dome-of-Protection trips, adjust the DOP Range Con-

trol for the minimum setting required to detect the violation. Turn the

DOP Range Control knob clockwise to increase the size of the dome.

Note: After adjustment, be sure to return the jumpers to their re-

spective positions as the unit is forced into an alarm condition in the

Dome-of-Protection adjustment mode.

DOP Operation

To understand how the Dome of Protection operates, it must first

be clear that, even though the LED indicates entry into the dome, (a)

violation of the dome does not immediately cause a trouble output;

(b) the Dome of Protection cannot be reset for at least 5 seconds;

and (c) the trouble will be cancelled if the unit detects motion outside

the dome by both technologies (verifying that the unit is operating); if

no motion is detected within 90 seconds, a trouble is output to the

control panel. This trouble may be reset by allowing the unit to detect

motion.

So long as motion is detected within the dome, a trouble will not be

output. The intruder (whether it be the installer, a maintenance man,

etc.) leaving the dome, will be detected by both technologies, cancel-

ing the Dome-of-Protection trouble. If the intruder attempts to tamper

with the unit or to defeat its function, as by masking or blocking the

lens, he will not be detected by both technologies and a trouble will be

output within 1 minutes. Similarly, if a large object (such as a skid of

boxes) is placed in front of the dome, a trouble will be output within 1

minutes.

CAUTION: The Dome of Protection may be used only where there

is no possibility of disturbances in close proximity to the sensor (within

the dome). Beware of such conditions as loose ceiling tiles, which

could violate the dome without resetting it. In an environment such as

this, the Dome of Protection should be disabled by reducing the D-O-

P Range Control fully counterclockwise to "Off/Disabled". For best

security when using DOP, the lookdown feature should be dis-

abled by either removing the small lookdown lens located just

below the PIR sensor element, or blocking the lookdown win-

dow located at the bottom of the front cover.

IMPORTANT: Do NOT wire Dome of Protection relay in series

with alarm loop. Use a separate trouble non-alarm zone.

NAPCO SECURITY SYSTEMS, INC. (NAPCO) warrants its products

to be free from manufacturing defects in materials and workmanship for

thirty-six months following the date of manufacture. NAPCO will, within

said period, at its option, repair or replace any product failing to operate

correctly without charge to the original purchaser or user.

This warranty shall not apply to any equipment, or any part thereof,

which has been repaired by others, improperly installed, improperly used,

abused, altered, damaged, subjected to acts of God, or on which any

serial numbers have been altered, defaced or removed. Seller will not be

responsible for any dismantling or reinstallation charges.

THERE ARE NO WARRANTIES, EXPRESS OR IMPLIED, WHICH

EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

THERE IS NO EXPRESS OR IMPLIED WARRANTY OF MERCHANT-

ABILITY OR A WARRANTY OF FITNESS FOR A PARTICULAR PUR-

POSE. ADDITIONALLY, THIS WARRANTY IS IN LIEU OF ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PART OF NAPCO.

Any action for breach of warranty, including but not limited to any im-

plied warranty of merchantability, must be brought within the six months

following the end of the warranty period. IN NO CASE SHALL NAPCO

BE LIABLE TO ANYONE FOR ANY CONSEQUENTIAL OR INCIDEN-

TAL DAMAGES FOR BREACH OF THIS OR ANY OTHER WAR-

RANTY, EXPRESS OR IMPLIED, EVEN IF THE LOSS OR DAMAGE IS

CAUSED BY THE SELLER’S OWN NEGLIGENCE OR FAULT.

In case of defect, contact the security professional who installed and

maintains your security system. In order to exercise the warranty, the

product must be returned by the security professional, shipping costs pre-

paid and insured to NAPCO. After repair or replacement, NAPCO as-

sumes the cost of returning products under warranty. NAPCO shall have

no obligation under this warranty, or otherwise, if the product has been

repaired by others, improperly installed, improperly used, abused, altered,

damaged, subjected to accident, nuisance, flood, fire or acts of God, or on

which any serial numbers have been altered, defaced or removed.

NAPCO will not be responsible for any dismantling, reassembly or rein-

stallation charges.

This warranty contains the entire warranty. It Is the sole warranty

and any prior agreements or representations, whether oral or writ-

ten, are either merged herein or are expressly cancelled. NAPCO

neither assumes, nor authorizes any other person purporting to act

on its behalf to modify, to change, or to assume for it, any other war-

ranty or liability concerning its products.

In no event shall NAPCO be liable for an amount in excess of

NAPCO's original selling price of the product, for any loss or damage,

whether direct, indirect, incidental, consequential, or otherwise arising out

of any failure of the product. Seller’s warranty, as hereinabove set forth,

shall not be enlarged, diminished or affected by and no obligation or liabil-

ity shall arise or grow out of Seller’s rendering of technical advice or ser-

vice in connection with Buyer’s order of the goods furnished hereunder.

NAPCO RECOMMENDS THAT THE ENTIRE SYSTEM BE COM-

PLETELY TESTED WEEKLY.

Warning: Despite frequent testing, and due to, but not limited to, any or

all of the following; criminal tampering, electrical or communications dis-

ruption, it is possible for the system to fail to perform as expected.

NAPCO does not represent that the product/system may not be compro-

mised or circumvented; or that the product or system will prevent any per-

sonal injury or property loss by burglary, robbery, fire or otherwise; nor

that the product or system will in all cases provide adequate warning or

protection. A properly installed and maintained alarm may only reduce

risk of burglary, robbery, fire or otherwise but it is not insurance or a guar-

antee that these events will not occur. CONSEQUENTLY, SELLER

SHALL HAVE NO LIABILITY FOR ANY PERSONAL INJURY, PROP-

ERTY DAMAGE, OR OTHER LOSS BASED ON A CLAIM THE PROD-

UCT FAILED TO GIVE WARNING. Therefore, the installer should in turn

advise the consumer to take any and all precautions for his or her safety

including, but not limited to, fleeing the premises and calling police or fire

department, in order to mitigate the possibilities of harm and/or damage.

NAPCO is not an insurer of either the property or safety of the user’s

family or employees, and limits its liability for any loss or damage including

incidental or consequential damages to NAPCO’s original selling price of

the product regardless of the cause of such loss or damage.

Some states do not allow limitations on how long an implied warranty

lasts or do not allow the exclusion or limitation of incidental or consequen-

tial damages, or differentiate in their treatment of limitations of liability for

ordinary or gross negligence, so the above limitations or exclusions may

not apply to you. This Warranty gives you specific legal rights and you

may also have other rights which vary from state to state.

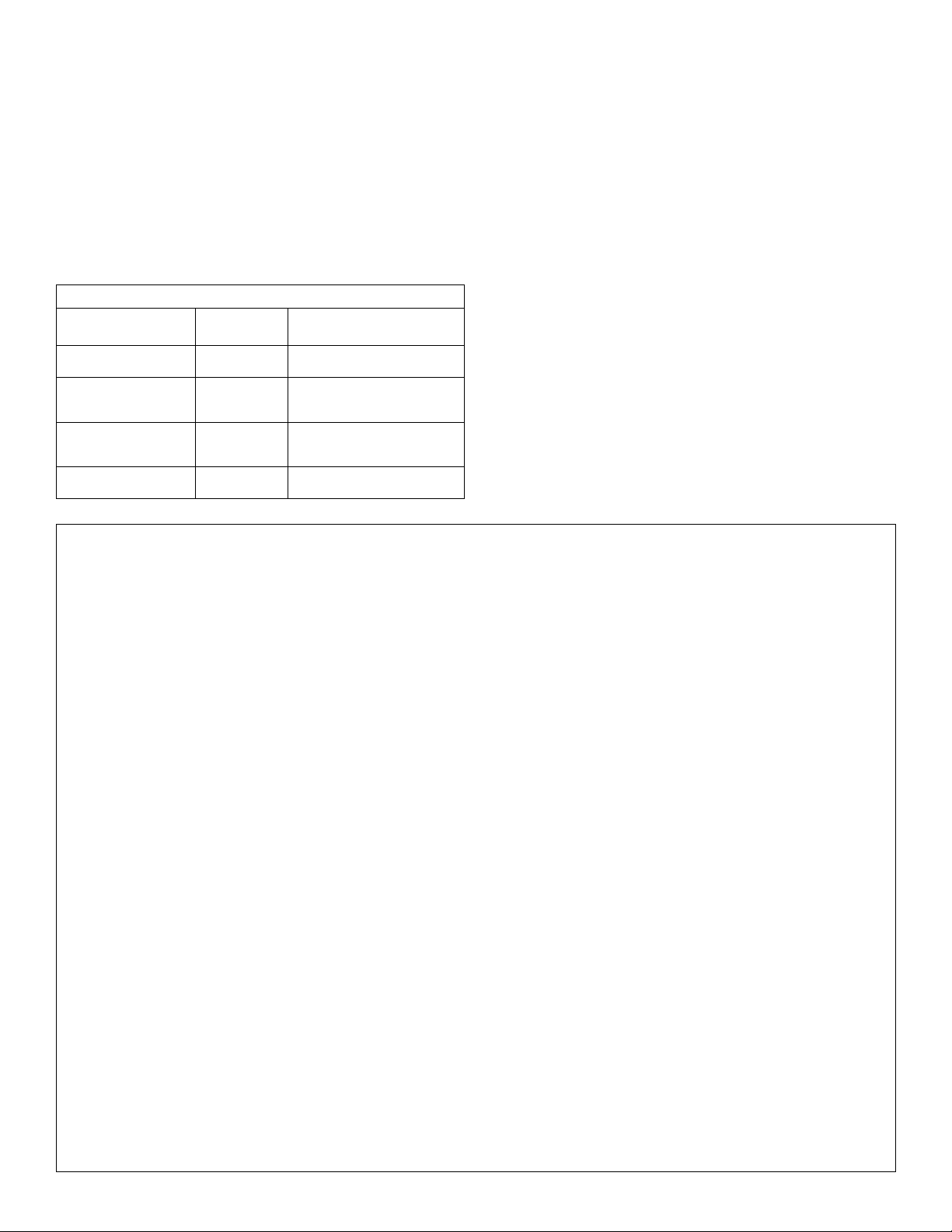

NAPCO LIMITED WARRANTY

SYMPTOM PROBABLE

CAUSE

REMEDY

LED flashing 1 second on,

one second off

DOP violation Check for masking followed by

walk test.

Unit holding loop in alarm Walk-Test Mode

selected.

Check jumper is in Alarm or LED

Disable position.

TROUBLESHOOTING GUIDE

Rapid LED flash, twice a

second

Microwave failure Power down for 5 seconds. Power

up again and wait 1½ minutes. If

symptom persists, return for repair.

High speed LED winking

flash.

PIR Failure Power down for 5 seconds. Power

up again and wait 1½ minutes. If

symptom persists, return for repair.