1

W415-0682 / B / 06.10.10

$10.00

INSTALLATION

INSTRUCTIONS

INSTALLER: LEAVE THESE INSTRUCTIONS WITH THE APPLIANCE THIS TERMINAL IS SERVING.

CONSUMER: RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE.

THESE INSTRUCTIONS ARE TO BE USED IN CONJUNCTION WITH THE APPLIANCE AND PVA INSTRUCTIONS.

CERTIFIED

Wolf Steel Ltd., 24 Napoleon Rd., Barrie, ON, L4M 4Y8 Canada /

103 Miller Drive, Crittenden, Kentucky, USA, 41030

ID[ZZZQDSROHRQILUHSODFHVFRPDVN#QDSROHRQRQFD

ZZZFRQWLQHQWDOILUHSODFHVFRPDVN#FRQWLQHQWDOILUHRQFD

CERTIFIED UNDER CANADIAN AND AMERICAN NATIONAL STANDARDS: ANSI Z21.88 CSA 2.33 FOR VENTED GAS FIREPLACE HEATERS

AND ANSI Z21.50 CSA 2.22 FOR GAS FIREPLACES.

GENERAL INFORMATION

These Installation Instructions must be used in conjunction

with the appliance and appropriate PVA adapter kit Installation

Instructions. Clearances listed in these Instructions supersede

those in the appliance's Installation Instructions.

Power venting of direct vent appliances may result in the

reduction of efficiencies by as much as ten percent. Consider

this in making any venting and heating decisions in any

installation application.

SELECTING AND INSTALLING THE FIREPLACE

When selecting a gas appliance for use with the GPV, take into

consideration the various requirements and limitations in the

venting installation section for the following models:

Models Equipped with an Intermittent Pilot Ignition (I.P.I.)

It is recommended that the GPV be used with a gas appliance

equipped with an Intermittent Pilot Ignition (I.P.I.). Downward

vertical vent runs are permitted with an I.P.I. system. See

venting section in appropriate PVA Installation Instructions.

Models Equipped with Millivolt/ Standing Pilot

Downward vertical vent runs are not permitted with a standing

pilot system. See venting section in appropriate PVA Installation

Instructions.

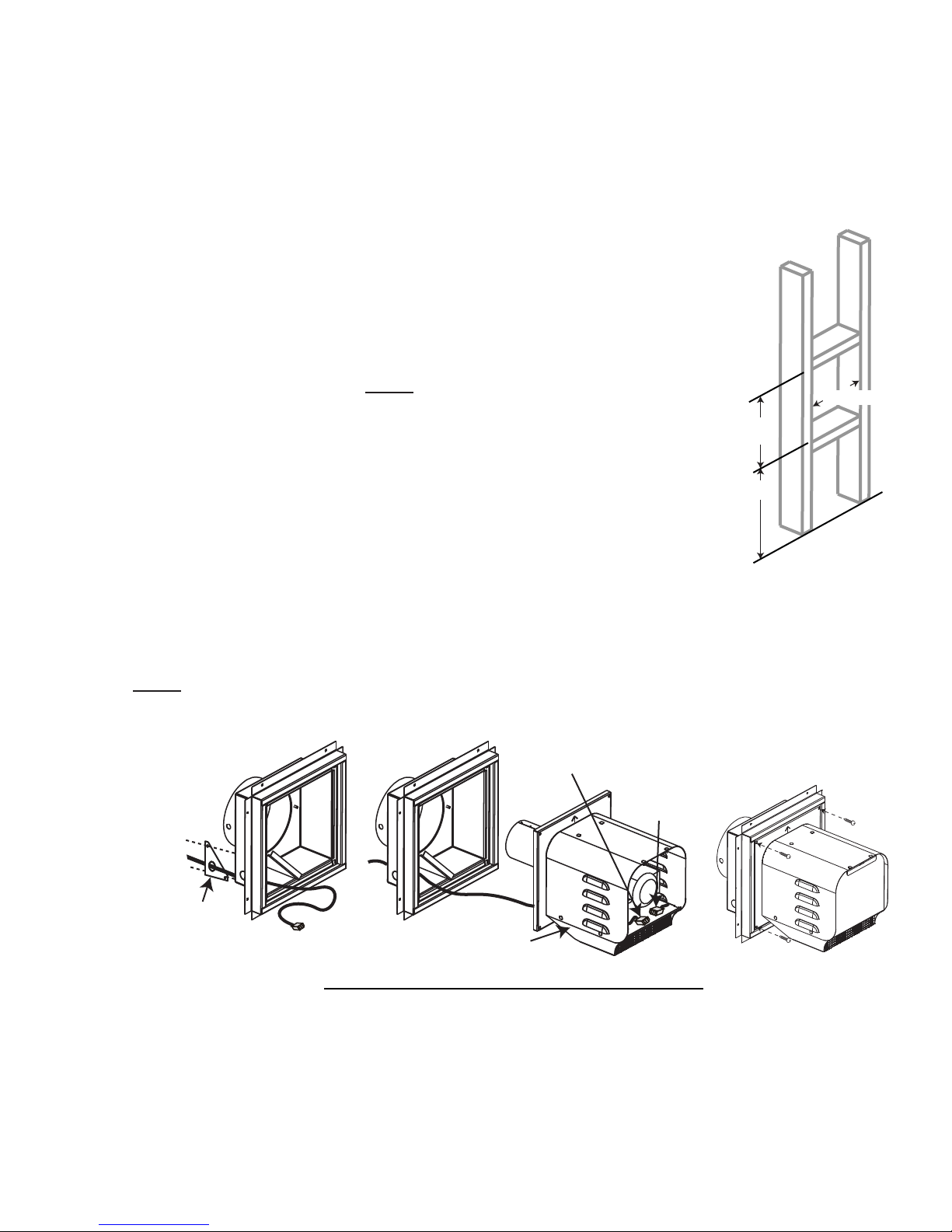

INSTALLATION TO BE DONE BY A QUALIFIED INSTALLER

to conform with local codes. In absence of local codes install

to the current National Building Code in Canada or to regional

building codes in the United States. It must be electrically

connected and grounded in accordance with local codes. In

the absence of local codes, use the current CSA C22.1

CANADIAN ELECTRICAL CODE in Canada or the ANSI/NFPA

70 NATIONAL ELECTRIC CODE in the United States.

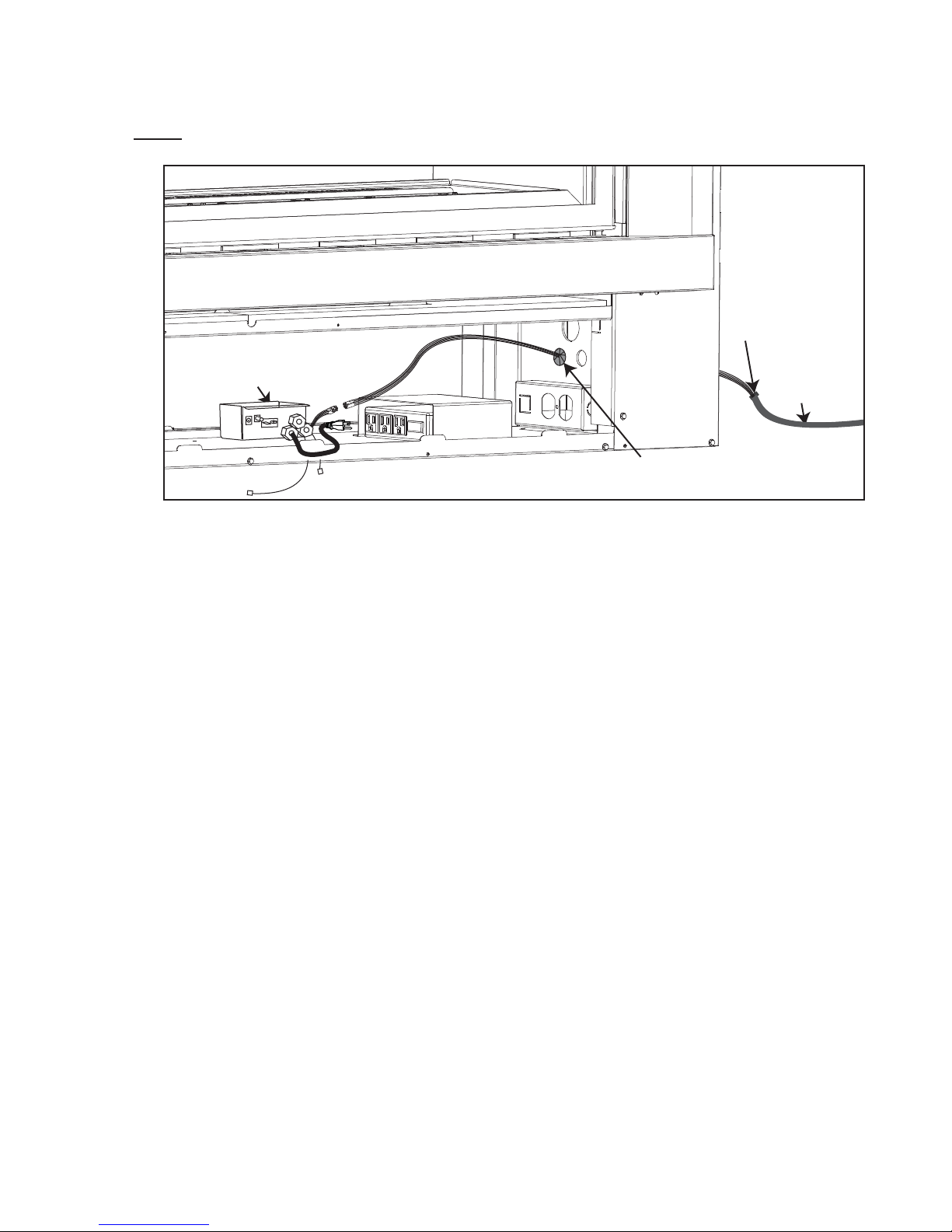

The GPV operates on 120 VAC 60 HZ electrical service which is

supplied at the firebox junction box.

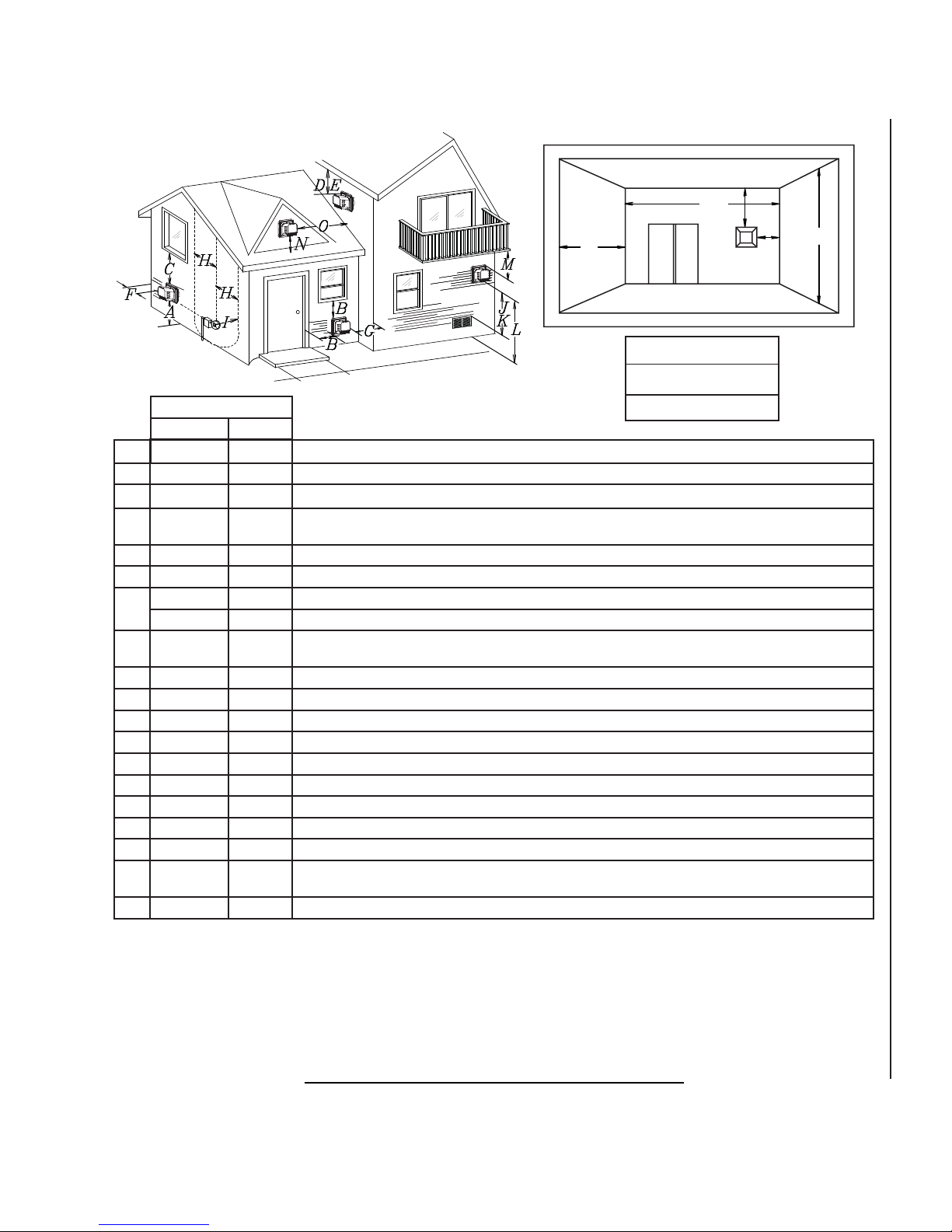

GAS POWER VENT

(GPV) The GPV is a Direct Vent Terminal

designed to allow installation of

gas appliances where typical vent

configurations cannot be achieved.