4

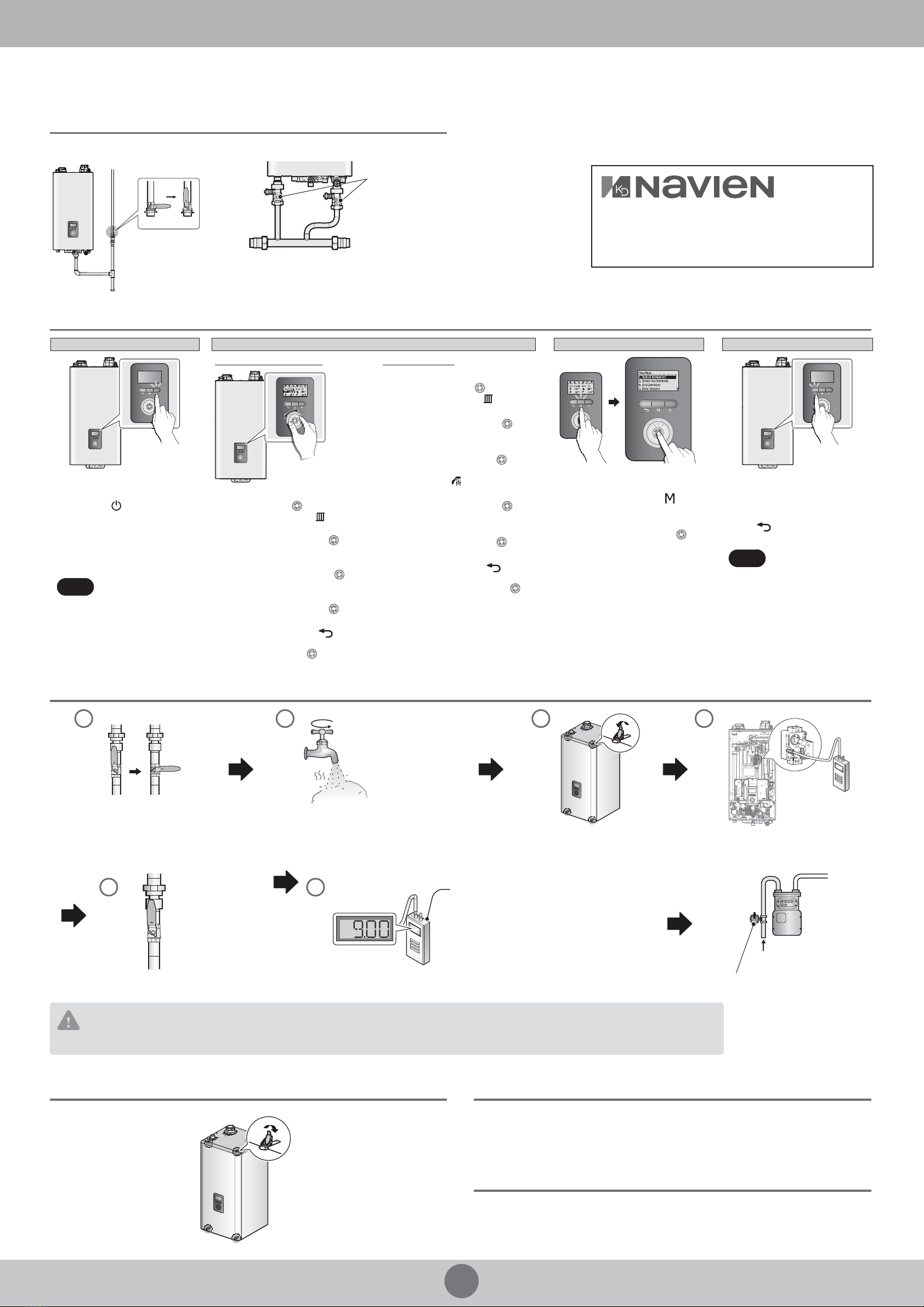

STEP 3 After Installing

Opening All the Valves

>

Gas Valve Space Heating System Valves

23(1

&/26(

3(1

/

(

23(1

&/26(

23(1

&/26(

Gas Valve

OpenedClosed

Shut-o

valves

Power ON Adjust Temperatures View Basic Information Resetting the Boiler

Space Heating Temperature DHW Temperature

1. In normal operation mode, rotate

the Command dial ( ). The space

heating temperature ( ) is

highlighted on the screen.

2. Rotate the Command dial ( ) to

the right to select the DHW

temperature.

3. Press the Command dial ( ) to

select the indirect DHW

temperature ( ). The highlighted

section will ash.

4. Rotate the Command dial ( )to

the right or left to increase or

decrease the temperature.

5. Press the Command dial ( ) to

conrm the new temperature.

6. Press the Back button ( ) to

return to normal operation mode,

or rotate the Command dial ( )

to adjust other operation

conditions.

To turn the boiler on, press the

Power button ( ).

When the power is on, the boiler

automatically enters normal

operation mode, and the boiler’s

operating conditions are displayed

on the screen.

Note

The setup wizard should

run the rst time the unit

is powered on. The wizard

must be completed

before the boiler can be

used. Refer to page 108 in

the Installation &

Operation Manual.

1. In normal operation mode, rotate the

Command dial ( ). The space

heating temperature ( ) is

highlighted on the screen.

2. Press the Command dial ( )to select

the space heating temperature. The

highlighted section will ash.

3. Rotate the Command dial ( )to the

right or left to increase or decrease

the temperature.

4. Press the Command dial ( )to

conrm the new temperature.

5. Press the Back button ( ) to return

to normal operation mode, or rotate

the Command dial ( ) to adjust

other operation conditions.

1. Press the Menu button ( ), and

then select “1. Status

Information”.

2. Rotate the Command dial ( ) to

switch between the information

items.

If an error message appears during

boiler operation, reset the boiler to

resolve the problem. Press the Back

button ( ) on the front panel to

reset the boiler.

Note If resetting does not

solve the problem, refer

to the troubleshooting

section of the User’s

Information Manual or

contact the service

center.

23(1

&/26(

23(1

&/26(

1

Open Closed

2

Open a hot water

faucet. The boiler

should turn on and

the gas in the gas

supply line will be

purged.

3 4

Digital pressure

manometer

Shut o the manual gas valve. Leave the faucet on until the boiler shuts down

due to a lack of gas supply, and then turn o the

hot water faucet.

Unfasten the 4 latches (2 at the top

and 2 at the bottom) to remove

the front cover and gain access to

the internal components.

Loosen the screw indicated in the gure and

connect a manometer to the pressure port.

Reset the manometer to zero before use.

23(1

&/26(

5

Open

Re-open the manual

gas valve and check

for leaks.

Activate multiple

zones to ramp the

boiler up to its

maximum ring rate.

6

NG: 3.5”–10.5”WC

LP: 8.0”–13.0”WC

Recommended

Gas Pressure Settings:

When the boiler reaches its maximum ring rate,

check the inlet gas pressure reading on the manometer.

If not,

Gas supply

Adjust the inlet gas pressure with gas regulator.

CAUTION

The boiler cannot function properly without sucient inlet gas pressure. Measuring the inlet gas pressure should be performed by a licensed professional only.

Navien, Inc.

20 Goodyear, Irvine, CA 92618

Tel: 1-800-519-8794, Fax: 1-949-420-0430

www.navieninc.com

Installing the Front Cover

>

Ensure Maximum Water Flow

>

After running the boiler for the rst 10 minutes, turn it o and clean the cold water lter

and the space heating return strainer to remove any trapped debris.

Final Check

>

A trial run should be performed in accordance with the Installation checklist listed in

the boiler’s Installation & Operation Manual.

Operating the Boiler

>

Measuring the Inlet Gas Pressure

>