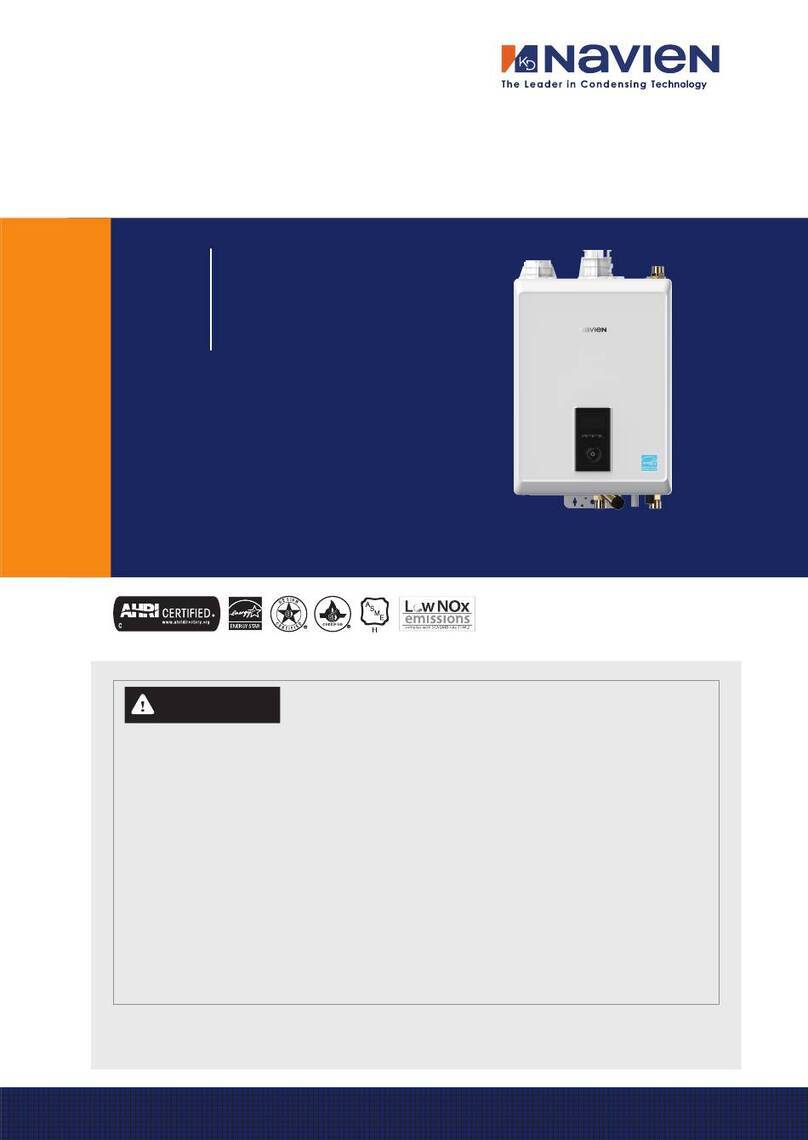

Combination Boiler

Model

NCB-180/210/240

This boiler is configured for Natural Gas

from the factory. If conversion

to Propane Gas is required, the

conversion kit supplied with the boiler

must be used.

WARNING

This conversion kit shall be installed by a qualified service agency* in

accordance with Navien America’s instructions and all applicable codes and

requirements of the authority having jurisdiction. The information in these

instructions must be followed to minimize the risk of fire or explosion or to

prevent property damage, personal injury or death. The qualified service

agency is responsible for the proper installation of this kit. The installation is

not proper and complete until the operation of the converted appliance is

checked as specified in the manufacturer’s instructions supplied with the kit.

٭

A qualified service agency is any individual, firm, corporation or company

which either in person or through a representative is engaged in and is

responsible for the connection, utilization, repair or servicing of gas

utilization equipment or accessories; who is experienced in such work,

familiar with all precautions required, and has complied with all of the

requirements of the authority having jurisdiction.

: The conversion shall be carried out in accordance with

the provincial authorities having jurisdiction

and in accordance with the requirements of the CAN

CAN1‐B149.2 Installation Code.

5/32 in or 4mm Allen Wrench

Combustion Analyzer or Dual Port Manometer

Gas Orifice (refer to below table)

NCB-210 Ø6.10 Ø6.30 Ø4.50 Ø4.80

Gas Pressure and Conversion Kit Number Labels

Once the Gas Orifice is exposed, remove the two screws that

hold the part in place. Remove the Gas Orifice from its housing

and prepare the new Gas Orifice for the LP conversion for

installation.

Figure 4. Access to Gas Orifice in Fan Assembly

WARNING

DO NOT adjust or attempt to measure gas valve outlet

pressure. The gas valve is factory-set for the correct outlet

pressure. This setting is suitable for natural gas and propane,

requiring no field adjustment.

Attempting to alter or measure the gas valve outlet pressure

could result in damage to the valve, causing potential severe

personal injury, death or substantial property damage. Navien

NCB boilers are shipped ready to fire natural gas ONLY.

Figure 5. Exploded View of Gas Pipe Assembly

DANGER

See Figure 5. Inspect the O-ring between the gas valve and gas valve inlet

adapter whenever they are disassembled. The O-

condition and must be installed. Failure to comply will cause a gas leak,

resulting in severe personal injury or death.

Procedure:

1. Turn off both gas and water supply to the boiler.

2. Using a Phillips screwdriver, remove 4 screws (2 from the top and 2 from

the bottom) of the front cover assembly to gain access to the internal

components. See Figure 1 for illustration of the front cover on the unit.

3. Once the front cover is removed, place it in a safe location to prevent

accidental damage.

4. Label all the wires on the PCB.

5. Disconnect all the wires.

6. Loosen the three screws indicated in the figure. (Refer to Figure 2.)

. Remove the PCB assembly.

. With the internal components exposed, locate the gas inlet

pipe and the gas valve in the middle of the unit.

Use a Phillips screwdriver to remove the two screws at location

A - the connection below the gas valve where it connects to the

pipe. See Figure 3 for reference. Once the screws are removed,

carefully separate the pipe from the gas valve.

Once the gas inlet pipe is detached from the gas valve, find

location B - the connection above the gas valve where it is

attached to the fan motor assembly. Carefully remove the four

screws by hand using a Phillips screwdriver and pull the gas

valve away from the fan assembly to access the gas orifice.

Figure 3. Detaching Gas Valve from

Gas Inlet Pipe and Fan Motor Assembly

Figure 6. Orifice identification

12.

Replace the old Orifice piece with the new part for use with LP

gas. Ensure that the Orifice is properly seated inside the port

before proceeding to the next step.

13.

Replace the gas inlet pipe to its original position and use all

screws to secure all connections.

Do not overtighten as this may damage or crack the

DANGER

Inspect the O-ring between the gas valve and gas valve inlet adapter

whenever they are disassembled. The O-ring must be in good condition

and must be insta

lled. Failure to comply will cause a gas leak, resulting

in severe personal injury or death.

14.

Place the PCB assembly back on to the boiler and tighten the

three screws.

15.

Check the labels carefully and then connect all the wires.

16.

Set the front panel Dip Switch to change the gas type. For LP, set Dip

Switch 2 #2 to On. For NG, set DIP SW2 #2 to Off.

WARNING

Ensure that you have turned off the power to the boiler before accessing the

DANGER

When conversion is required, be sure to set the front panel DIP

switches according to the supply gas type.

Failure to properly set the DIP switches could cause carbon

monoxide poisoning, resulting in severe personal injury or death.

17.

Turn on the gas and water supply to the boiler.

Location B: Remove

4 screws here

Remove two (2)

screws here