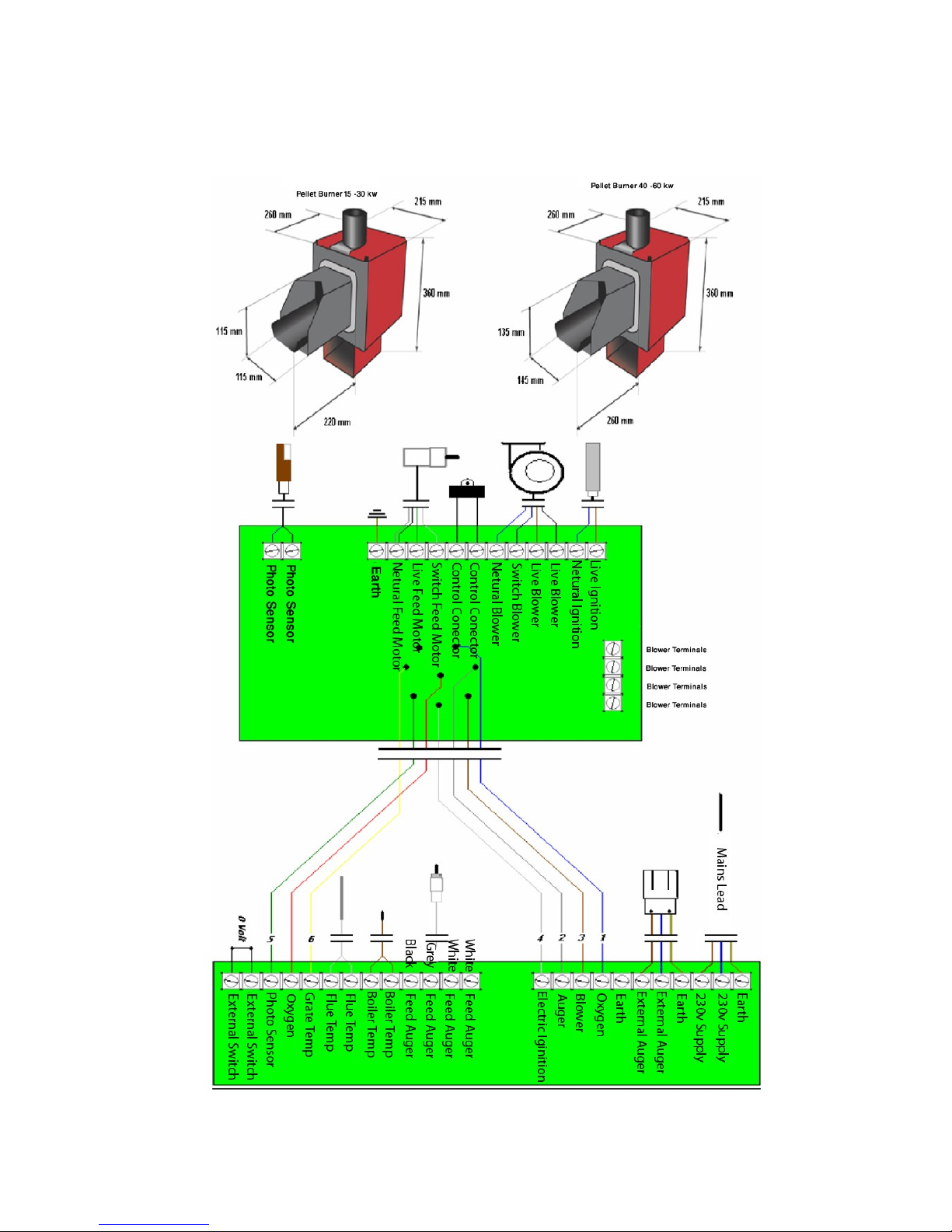

Section 5

Starting the unit for the first time.

1. check all connections on burner, boiler, feed screw, flue, chimney and

power supply.

2. ensure that there are pellets at the inlet of the feed screw in the pellet

silo.

3. activate the forced feed operation by pressing the UP button on the

controller for 10 seconds and turn the mains power on at the same time.

4. when the feed screw has filled with pellets and they are falling into the

burner, turn the power off at mains.

5. The burner is started by switching the mains power on again. The control

box can be started/stopped by pressing the on/off button for 8 seconds.

6. The alarm is cancelled by pressing the DOWN button 2 times within 8

seconds.

To obtain the optimum efficiency from the burner and boiler, correct

adjustment is essential.

Please refer to section 5 on adjusting the burner and section 6 on

cleaning the burner.

Adjusting the burner.

For first time start up, refer to quick start guide on page 15.

The outputs for high and low loads are run by the control system in a 100 step

modulation and the changes between the different steps are made automatically.

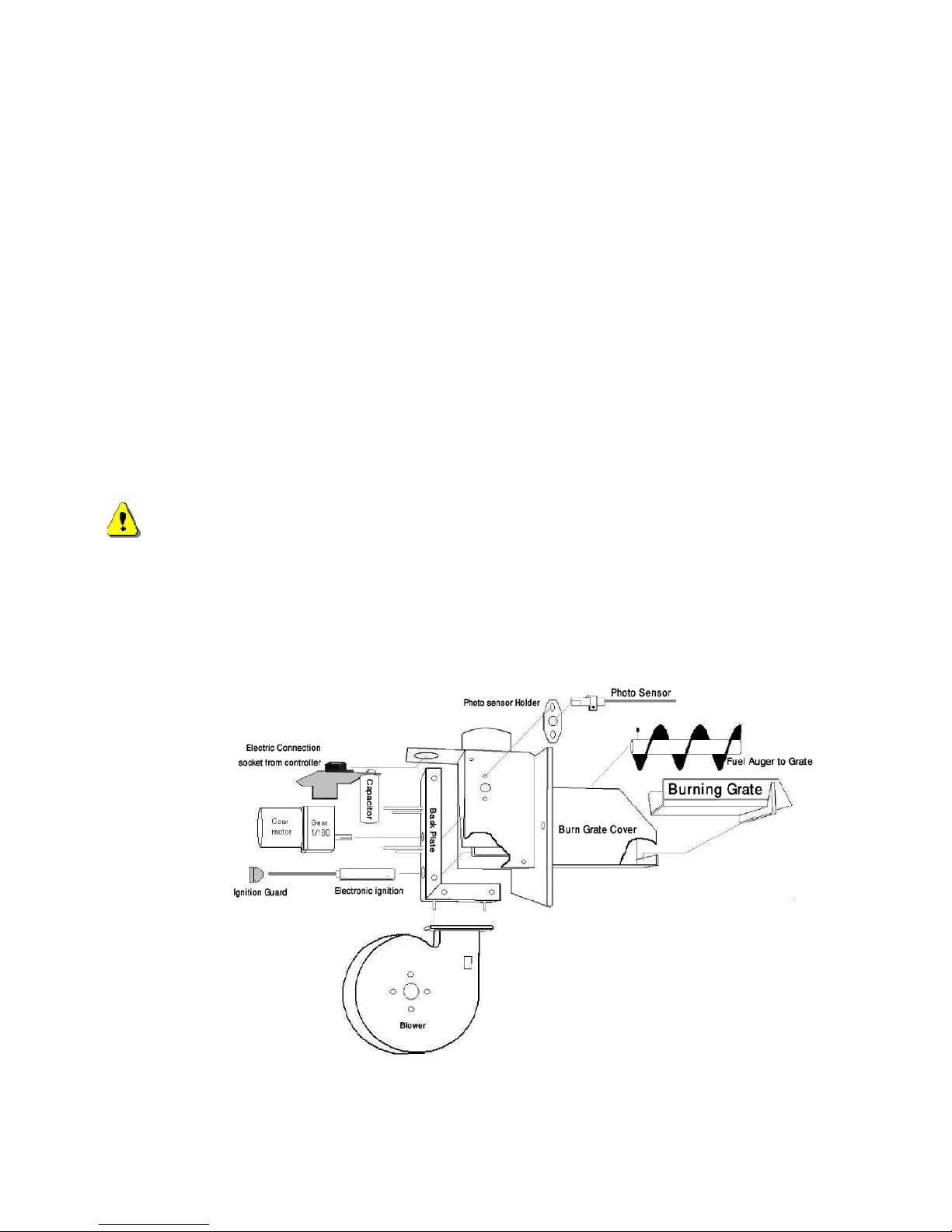

Feed adjustments for high and low loads.

Wood pellets can vary (dust, pellet length etc.) so correct adjustment for fuel

economy and boiler efficiency are essential. The feed screw will supply the pellets

differently and will have an influence on the burn quality. It is necessary to open

the doors to the burner and look at the flame.

If the flame is fat – dark, possibly with black points, or the ash is black with

black pellets, fewer pellets are needed. Reduce steps 2 and 3 in the main menu.

If the flame is thin – little flame and like a sparkler, or the ash is light grey,

more pellets are needed. Increase steps 2 and 3 in the main menu.

* Correct burning adjustments normally produce a dark grey ash. *

The burner is intended for wood pellets between 6-8mm diameter.

If you are in any doubt then subscribe to a service contract. For further

information visit : www.nordjysk-bioenergi.dk

Page 8