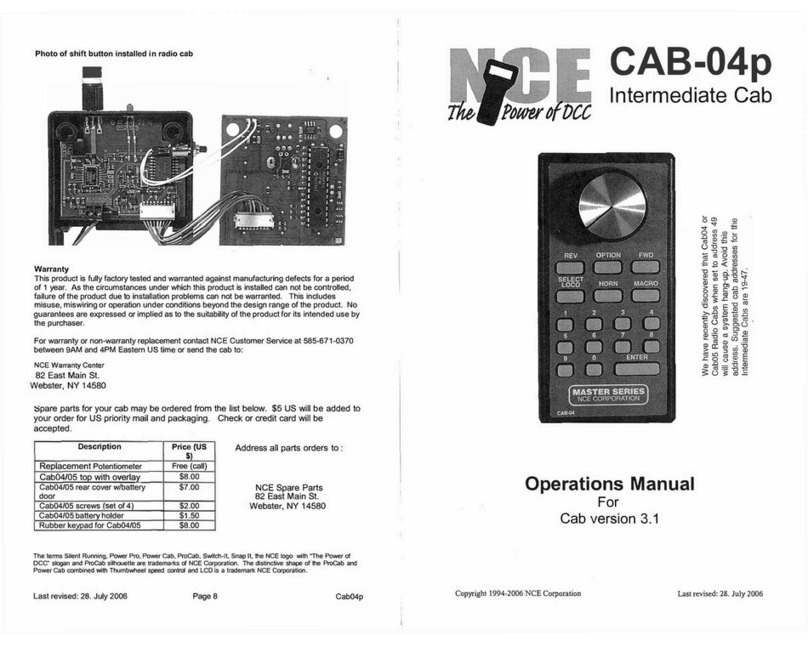

8

TABLE OF CONTENTS

QUICK START ............................................................................................................ 1

COMPLETING THE QUICK START ......................................................................... 2

PROGRAMMING A LOCOMOTIVE ADDRESS ....................................................... 2

RUNNING TWO LOCOMOTIVES WITH ONE CAB ................................................ 3

CUSTOMER SERVICE............................................................................................... 4

REGISTER MY SYSTEM… WHY? ............................................................................ 4

TABLE OF CONTENTS ............................................................................................. 6

INSTALLING DECODERS ......................................................................................... 8

PRECAUTIONARY NOTES FOR DECODERS........................................................ 9

GENERAL SYSTEM INSTALLATION...................................................................... 10

DEVICE LOCATIONS........................................................................................... 10

PROGRAMMING TRACK .................................................................................... 10

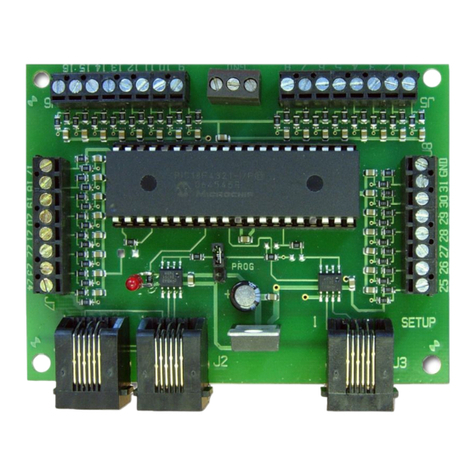

NCE AUTO SWITCH ............................................................................................ 11

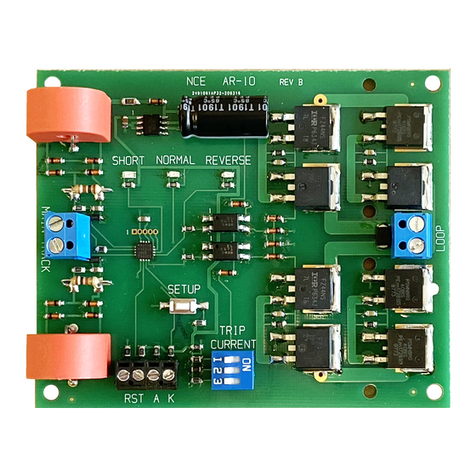

REVERSE BLOCKS, WYES, AND CROSSOVERS ........................................... 11

WIRING.................................................................................................................. 11

SYSTEM POWER PANEL DESCRIPTION ............................................................. 12

THE POWER CABTM SYSTEM UNIT ....................................................................... 13

SET THE PRO CABTM ADDRESS............................................................................ 14

THE LCD SCREEN ............................................................................................... 14

LOCOMOTIVE CONTROL AREA ....................................................................... 14

SPEED CONTROL SECTION ............................................................................. 15

COMMONLY USED BUTTONS........................................................................... 15

LOCO AND ACCESSORY SELECTION GROUP ............................................. 16

DATA ENTRY/FUNCTION CONTROL............................................................... 16

CONSIST SETUP GROUP .................................................................................. 16

PROGRAMMING AND EXTENDED FUNCTION CONTROL........................... 17

CAB SETUP ........................................................................................................... 18

CAB BUTTON NUMBERING SCHEME .............................................................. 20

TABLE OF FACTORY DEFAULT VALUES ........................................................ 21

6 WIRE CAB BUS CABLE WITH RJ-12 CONNECTORS .................................. 21

4 WIRE CAB BUS CABLE WITH RJ-12 CONNECTORS .................................. 22

POWER CABTM SPECIFICATIONS ......................................................................... 22

OPERATING PROCEDURES .................................................................................. 23

THE “NORMAL” DISPLAY.................................................................................... 23

SELECTING A LOCOMOTIVE OR CONSIST ................................................... 23

CONTROLLING HEADLIGHTS AND OTHER DECODER FUNCTIONS........ 24

OLD AND ADVANCED CONSISTS EXPLAINED ................................................... 25

ADVANCED CONSISTS....................................................................................... 25

OLD STYLE CONSISTS (ALSO CALLED BRUTE FORCE OR UNIVERSAL) 25

SETTING UP AN ADVANCED CONSIST ............................................................... 25

DROPPING A LOCOMOTIVE FROM AN ADVANCED CONSIST................... 27

ADDING A LOCO TO AN ADVANCED CONSIST............................................. 27

CLEARING AN ADVANCED CONSIST .............................................................. 28

CHANGING THE LEAD/REAR LOCO ................................................................ 28

OLD STYLE CONSISTS........................................................................................... 29

SETUP AN OLD STYLE CONSIST ..................................................................... 29

ADDING A REAR LOCO TO AN OLD STYLE CONSIST ................................. 29

CLEARING AN OLD STYLE CONSIST .............................................................. 30

CONTROLLING TURNOUTS AND OTHER ACCESSORIES.............................. 31

MOMENTUM BUTTON ............................................................................................ 32

USING MACROS TO CONTROL TURNOUTS ..................................................... 33

MACROS EXPLAINED ......................................................................................... 33

PROGRAMMING PROCEDURES .......................................................................... 34

ACCESSING PROGRAMMING MODES ............................................................ 34

PROGRAMMING MENUS TABLE OF CONTENTS............................................. 35

PROGRAMMING ON THE MAIN ........................................................................ 37