Mitsubishi CR760-Q User manual

Other Mitsubishi Controllers manuals

Mitsubishi

Mitsubishi PAC-YG60MCA Service manual

Mitsubishi

Mitsubishi MELSEC-A series User manual

Mitsubishi

Mitsubishi MELSEC-A AJ71PT3 User manual

Mitsubishi

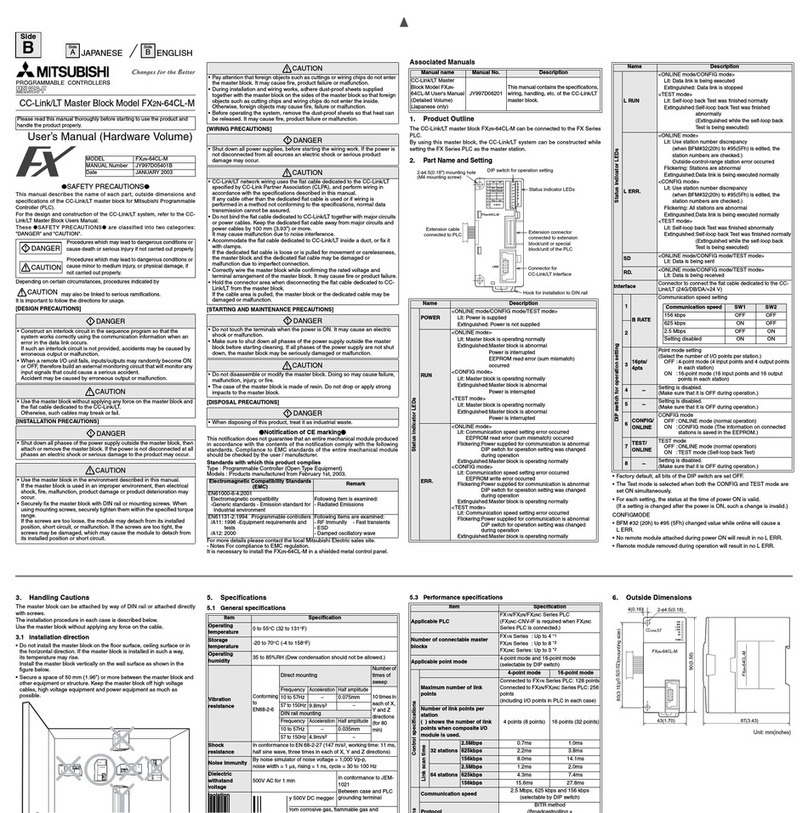

Mitsubishi FX2N-64CL-M User manual

Mitsubishi

Mitsubishi FX3U-485ADP(-MB) User manual

Mitsubishi

Mitsubishi FX2NC-485ADP User manual

Mitsubishi

Mitsubishi L02CPU User manual

Mitsubishi

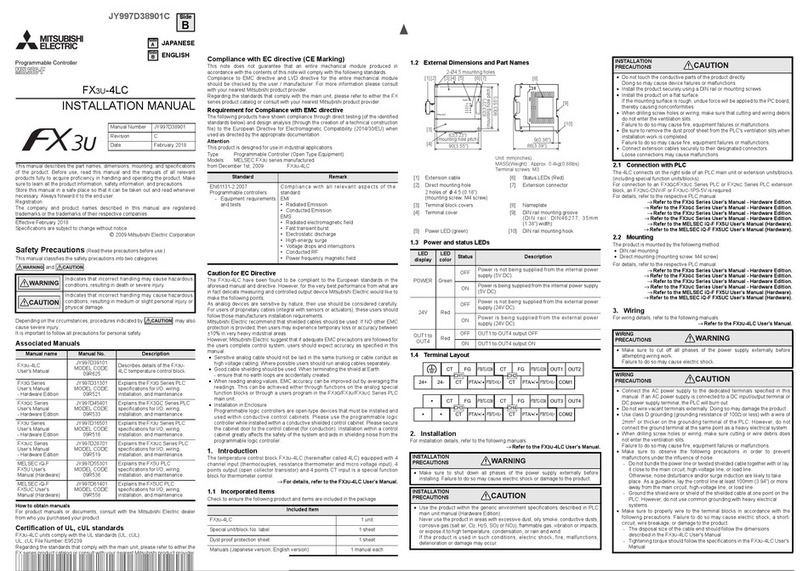

Mitsubishi FX3U-4LC User manual

Mitsubishi

Mitsubishi FBC15N User manual

Mitsubishi

Mitsubishi FX1S Series Owner's manual

Mitsubishi

Mitsubishi FX3U-USB-BD User manual

Mitsubishi

Mitsubishi MELSEC iQ-F FX5 series User manual

Mitsubishi

Mitsubishi AJ65BT-R2 User manual

Mitsubishi

Mitsubishi MELSEC System Q Owner's manual

Mitsubishi

Mitsubishi AG-150A User manual

Mitsubishi

Mitsubishi FX3U-32DP User manual

Mitsubishi

Mitsubishi A1SJ61BT11 User manual

Mitsubishi

Mitsubishi CMB-P-V-F User manual

Mitsubishi

Mitsubishi QJ71GP21S-SX User manual

Mitsubishi

Mitsubishi QS03NB-U-HW Instruction Manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions