Setting up CV’s and their values: Optional - Not Required

Method 1:

Any DCC system that has OPs mode programming (Program On the Main) for locomotives

can program CVs. Whenever the “SETUP” button is pressed the AR10 will flash the SHORT

LED at 1 second intervals indicating it is ready to respond to loco OPS mode programming no

matter what locomotive address is used. We recommend choosing an address that is not in

use on your layout (we use 9999). The SHORT LED must be flashing to use this method of

setting CVs. The LED will flash rapidly until an OPs programming command is received by the

AR10 or until 60 seconds has elapsed at which point the AR10 will return to normal

operations.

Using method 1 you must press SETUP before each CV you wish to program.

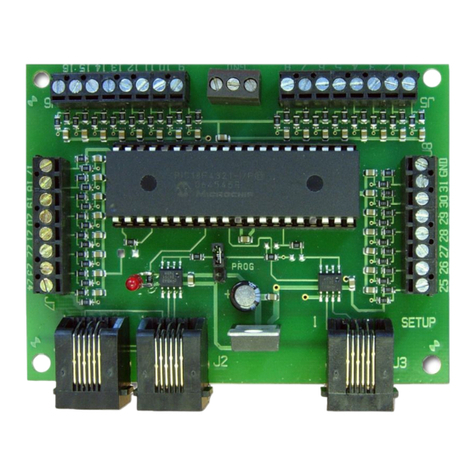

Method 2 (NCE Specific):

If you have an NCE (or other system) that supports OPs mode programming of accessories

you can program CVs without having to press the “SETUP” button for every CV.

The AR10 comes from the factory preprogrammed to the accessory address of 1.

To change the address:

Press the “SETUP” button (the LED will start flashing)

Press SELECT ACCY on your controller

Type in the new address you want to AR10 to use followed by ENTER

Press 1 (for NORMAL) when prompted on your controller

The LED will stop flashing and the AR10 will return to normal operations

The AR10 will now respond to Accessory Programming at the address you just programmed.

Using method 2 you will not need to press the SETUP again to program CVs when using

PROGRAM ACCESSORIES ON THE MAIN mode with an NCE system.

Fine Tuning the AR10

CV129 - Adjustment of short circuit response time (if necessary):

You can adjust the time delay between the occurrence of a short circuit and the time the track

actually gets shut down. The AR10 comes factory set to 16mS (16 milliseconds = 16

thousandths of a second). This setting has been chosen because it can be used without

problem on most layouts. You can lengthen this delay from 16ms (1/60th second) out to

512mS (1/2 second). Program CV129 to the number of milliseconds (divided by 16) you

desire between 16mS and 500mS. A value of 1 = 16mS, a value of 32 = 512mS, etc.

CV130 - Adjustment of short circuit shutdown time (if necessary):

You can adjust the time the track power stays off after a short circuit is detected. The AR10

comes factory set to 2 seconds. This setting has been chosen because it can be used

without problem on most layouts. You can change this delay anywhere from 16mS to 4

seconds. Program CV130 to the number of milliseconds (divided by 16) you desire. A value

of 1 = 16mS, a value of 125= 2 seconds, 250 = 4 seconds, etc.

CV131 - Manual reset enable.

If CV131 is set to 0 the manual reset is disabled and the AR10 will automatically try to turn on

track power after a short circuit. If CV131 is set to 1 the AR10 will not automatically restore

track power after a short circuit until a connection (usually with a pushbutton) is made

between he RST terminals of the four position terminal strip. You can also turn the track

power back on by selecting the accessory address and setting the accessory to ON (also

known as Normal, Thrown or +) .

**Last revised: 3 May 2020 Page 5 AR10