XDP-II User’s Guide

NDB Technologie Inc. 02/04/08 3

TABLE OF CONTENTS

1. Introducing the XDP-II.............................................................................................. 4

1.1. Partial Discharges............................................................................................. 4

1.2. The XDP-II ........................................................................................................ 4

1.3. Applications....................................................................................................... 4

2. Product Overview..................................................................................................... 5

2.1. Equipment and Accessories.............................................................................. 5

2.2. XDP-II Overview................................................................................................ 6

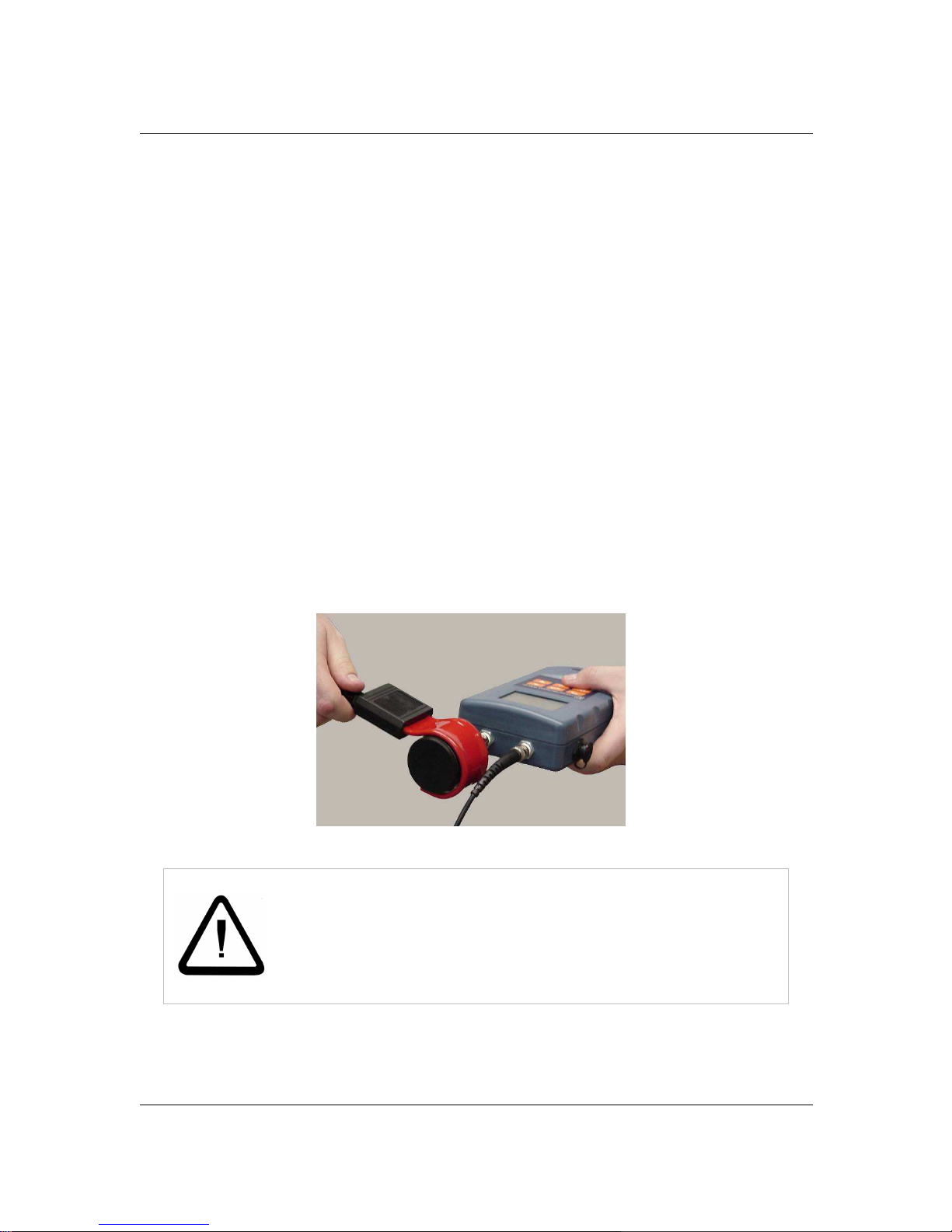

3. Calibration Check (when using xdp-302 capacitive sensor)..................................... 8

4. XDP-II Main Functions and Modes........................................................................... 9

4.1. Menus: .............................................................................................................. 9

4.2. Peak-Angle Mode.............................................................................................10

4.3. Analysis Mode..................................................................................................12

4.4. Edge Mode.......................................................................................................12

5. Applications.............................................................................................................13

5.1. XPLE/EPR TYPE Cable splice & elbow PD check...........................................13

5.2. Filters ...............................................................................................................14

5.3. Off-line partial discharge test kit (using a variable transformer) .......................16

5.4. Off-line partial discharge test kit (using a PD free source) ...............................20

5.5. Switchgears......................................................................................................24

6. Technical Specifications..........................................................................................25

6.1. XDP-II Characteristics......................................................................................25

6.2. Batteries...........................................................................................................25

6.3. Specifications...................................................................................................26