Nova Eclipse TG930 - Users Manual

14

to surface). Thickness readings should not be considered reliable if the

Coupling Indicator intermittently blinks, or flickers.

4.3 Basic Menu-Selections and Controls

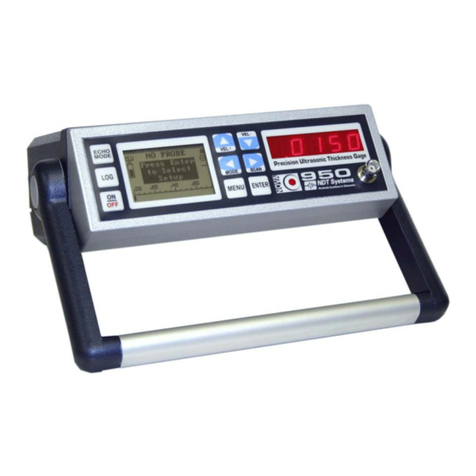

The numerous features that set the NOVA 930 apart from other handheld

thickness gages, and make it so easy to operate, are readily accessed

through intuitive Menus and Sub-Menus. Not all features will be used for

some applications. However, there are many unique User-selectable

features that can be accessed for difficult applications.

MAIN MENU

The Main Menu can be accessed at any time the

NOVA TG930 is powered on by pressing the

MENU Touch Command button. To exit any Menu

or Sub-Menu, press MENU, and the display will

revert to the last-displayed Menu, if in a Sub-Menu,

or to the Measurement display, if in the Main

Menu.

Main Menu Items are:

When the Main Menu is accessed, the first item, DISPLAY, is highlighted.

To scroll to the other items, use the Down and Up ARROW keys.

DISPLAY MENU: Press MENU to display the

Main Menu. By default, DISPLAY is highlighted.

Press the ENTER key. There are four selections

listed: Adjust Scale, Backlite, Contrast, and

Units. To select any of them, use the Down

ARROW key to sequentially highlight them.

Adjust Scale Sub-Menu (Scan Bar): In the

DISPLAY Menu, with Adjust Scale highlighted,

press ENTER. The Measurement Display will

open, as shown:

The objective is to set the range of expected

thicknesses in order to set up the Scan Bar and its

accompanying scale. Use of the Scan Bar is optional. It provides an

analog-like visual cue of acquired digital thickness readings. If it is desired

to use the Scan Bar, its scale can be set by establishing Start and Stop

Nova Eclipse TG930 - Users Manual

15

limits. It can start and end at any values within the NOVA TG930

specifications. Setting Start at a thickness somewhat below the minimum

expected thickness, and Stop at a somewhat greater thickness (say,

approximately 10%), than the maximum expected, will produce optimum

visual enhancement. For example, if the thickness of the test object is

expected to range between 0.050 and 0.100 inch (1.27 and 2.54mm), a good

Start point might be approximately 0.045 inch (1.14 mm) and the Stop point

at approximately 0.110 inch (2.80 mm). This range will produce the greatest

visual motion within the range of expected thickness. On the other hand,

under the example above, if the scale is set to Start and Stop at 0.000 and

2.500 inches (0.00 and 63.50 mm), the range of motion between the

minimum and maximum expected thicknesses would be a very small

proportion of the total scale.

From the example above, where the approximate thickness range is

expected to be from 0.050 and 0.100 inch (1.27 and 2.54mm), set the Stop

point first. With the Measurement Display open, and with Start highlighted,

as shown in the Figure above, use the Down ARROW to highlight Stop. If

the Stop value displayed is greater than the desired Stop point of 0.110 inch

(2.80 mm), press and hold the Left ARROW key. The Stop value will rapidly

scroll downward. At a Stop value approaching 0.110 inch (2.80 mm),

release the Left ARROW key, and toggle it until the desired value is

obtained. If the Stop value is less than that desired, use the Right ARROW

key to scroll/toggle the displayed value. To set the Start point at 0.045 inch

(1.14 mm), repeat the above procedure.

Finally, press the MENU button three times to back through the Adjust

Scale and DISPLAY Sub-Menus and return to the Measurement Display.

Observe that the Scan Bar scale ranges between the desired Start and Stop

values. Measurement readings between Start and Stop will produce the

analog view of the Scan Bar, and both the display reading and the Scan Bar

will remain displayed until the next valid reading is obtained.

If it is chosen not to use the Scan Bar, Adjust Scale settings can be set to

values below the Start value. Measurements within the expected range will

produce an off-scale Scan Bar. Regardless of the settings of the Scan Bar

scale, thickness readings and the accuracy of readings are unaffected.

Backlite Sub-Menu: In the DISPLAY Menu, toggle the Down ARROW to

highlight Backlite. Use the Right (or Left) ARROW to toggle through the

three selections, Auto, Off, and On. In the Auto mode the backlight will turn

on automatically when the transducer has valid coupling with the test object,